-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

SINUMERIK

SINUMERIK 828D

SINUMERIK 840D sl

SINUMERIK Operate — Milling

Control system overview

for machine tools’ sales people

Valid for:

Controls

SINUMERIK 828D / SINUMERIK 840D sl

Software

CNC software version 4.7

2017

A5E41992599B AA

___________________

Preface

___________________

Introduction

___________________

System overview

___________________

CNC operation with

SINUMERIK Operate

___________________

CNC operation in manual

mode (JOG)

___________________

Tool management

___________________

Data memory

___________________

Data transfer

___________________

CNC operation in automatic

mode (AUTO)

___________________

CNC functions

___________________

Tool and mold making

___________________

CNC programming methods

___________________

Workpiece visualization

___________________

CNC technology cycles

___________________

Complete machining

___________________

SINUMERIK Integrate Run

MyRobot

___________________

Tools and information

___________________

Safety functions

___________________

Summary of unique selling

points

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Summary of Contents for Siemens SINUMERIK 828D

(Ocr-Read Summary of Contents of some pages of the Siemens SINUMERIK 828D PPU Series Document (Main Content), UPD: 11 April 2023)

-

104, Switch S2 6FKDOWHU 6 Switch position: «ON» is at the top. Table 7-9 Switch S2 is set as delivered 1 2 3 4 5 6 7 8 9 10 Meaning ON ON PLC I/O Interface OFF OFF OFF OFF OFF OFF OFF OFF PROFINET address «0» The two switches S2-9 and S2-10 must remain set to «ON». The switches S2-1 to S2-8 define the PROFINET address. For a SINUMERIK 828D, the address «64» must always be assigned to …

-

175, Pin Signal name Type Pin Signal name Type 21 DI 2.2 I 22 DI 2.3 I 23 DI 2.4 I 24 DI 2.5 I 25 DI 2.6 I 26 DI 2.7 I 27 Not assigned — 28 Not assigned — 29 Not assigned — 30 Not assigned — 31 DO 0.0 O 32 DO 0.1 O 33 DO 0.2 O 34 DO 0.3 O 35 DO 0.4 O 36 DO 0.5 O 37 DO 0.6 O 38 DO 0.7 O 39 DO 1.0 O 40 DO 1.1 O 41 DO 1.2 O 42 DO 1.3 O 43 DO 1.4 O 44 DO 1.5 O 45 DO 1.6 O 46 DO 1.7 O 47 DOCOM1 VI 48 DOCOM1 VI 49 DOCOM1 VI 50 DOCOM1 VI VI: Voltage input/VO: Voltage Output I: Signal input/O: Signal ou…

-

194, Siemens SINUMERIK 828D PPU Series Name Color Status Meaning Activity Yellow Lit Sending or receiving Off No activity PROFINET address (S1) The right logical address must be assigned to the I/O module for communication with PLC I/O interface using the 10 bit DIP switch S1. Table 7-87 Switch S1 settings 1 2 3 4 5 6 7 8 9 10 Device name Meaning on on on off off on off off off off pp72x48pn9 1. PP module off off off on off off off off pp72x48pn8 2. PP m…

-

108, Parameter Value Temperature limits: ● Storage in acc. with EN 60721-3-1 ● Transportation (in transportation packaging) in acc. with EN 60721-3-2 ● Operation in acc. with EN 60721-3-3 -25 °C … 55 °C -25 °C … 55 ºC 0 … 45 ºC (front) 0 to 55 °C (rear) Cooling By natural convection Climate class ● Storage ● Transportation ● Operation 1K3 in acc. with EN 60721-3-1 2K4 in acc. with EN 60721-3-2 3K5 in acc. with EN 607…

-

166, 7.6 PP 72/48D PN 7.6.1 Description Features The I/O module is a simple module (without a separate enclosure) for connecting digital and analog input/outputs as part of an automation system based on PROFINET IO. The module has the following important features: ● 72 digital inputs and 48 digital outputs ● PLC I/O Interface connection (max. 100 MBaud) ● On-board status display via two diagnostic LEDs ● The three plug-in connector…

-

167, Illustration *URXQGLQJ VFUHZ 3/& ,2 ,QWHUIDFH ; ; ; ; ; 6 3RUW 3RUW /(‘V + + Figure 7-39 PP 72/48D PN I/O module Connectable components 7.6 PP 72/48D PN PPU Manual, 01/2014, 6FC5397-2DP40-3BA3 167

… -

159, Siemens SINUMERIK 828D PPU Series Additional options Optionally, you can use the following brackets for connection of the mini HHU: ● Angle box An angle box is available as an option, which permits the cable outlet direction to be rotated through 90°. Note The angular socket can only be used in conjunction with the non-assembled connection kit. ● Adapter plate To install the metal flange socket in the location for plastic flange sockets, an adapter plate is available. …

-

23, $UWLFOH QXPEHU 6HULDO QXPEHU ,’ QXPEHU +: YHUVLRQ &RPSRQHQW QDPH Figure 2-5 Horizontal PPU type plate $UWLFOH QXPEHU 6HULDO QXPEHU ,’ QXPEHU +: YHUVLRQ &RPSRQHQW QDPH Figure 2-6 Vertical PPU type plate Note MAC addresses The MAC addresses printed on the type plate of the PPU are required for configuring the PLC I/O Interface communications networks based on PROFINET and Industrial Ethernet. …

-

48, Panel cutout of the vertical PPU variant ① Mounting frame ② Pressure point for tensioners ③ Seal area Figure 4-5 Vertical PPU panel cutout Installing 4.1 Mounting positions PPU 48 Manual, 01/2014, 6FC5397-2DP40-3BA3

… -

144, Pin Signal name Type Pin Signal name Type 25 DI117.3 26 DO117.3 27 DI117.4 28 DO117.4 29 DI117.5 30 DO117.5 31 DI117.6 32 DO117.6 33 DI117.7 34 DO117.7 35 DI121.0 36 DI121.1 I 37 DI121.2 38 DI121.3 I 39 Reserved 40 Reserved Table 7-50 Assignment of connector X114 Pin Signal name Type Pin Signal name Type 1 Ground V 2 Ground V 3 DI118.0 I 4 DO118.0 O 5 DI118.1 6 DO118.1 7 DI118.2 8 DO118.2 9 DI118.3 10 DO118.3 1…

-

105, Byte Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0 EB115 RESET Keyswitch position 1 Single block Feedrate override E (2 4 ) D (2 3 ) C (2 2 ) B (2 1 ) A (2 0 ) EB116 Direction keys Keyswitch position 3 Axis selection + R15 — R13 Rapid traverse R14 X R1 4. axis R4 7. axis R7 R10 EB117 Axis selection Y R2 Z R3 5. axis R5 Drive command in MCS/WCS R11 9. axis R9 8. axis R8 6. axis R6 EB118 Unassigned customer key…

-

135, Rotary switch: Feed override X30 / spindle override X31 Connector designation: X30/X31 Connector type: 2 x 5-pin plug connector, according to EN 60603-13 with coding Table 7-31 Assignment of connector X30 / X31 Pin Signal name Signal type Meaning 1 N.C. — Not assigned 2 N.C. — Not assigned 3 M V Ground 4 N.C. — Not assigned 5 P5 V 5 V supply 6 DI122.4 / DI123.4 I Rotary override switch, position/value 16 7 DI122.3 / DI123.3 Rotary override switch, position/value 8 8 DI122…

-

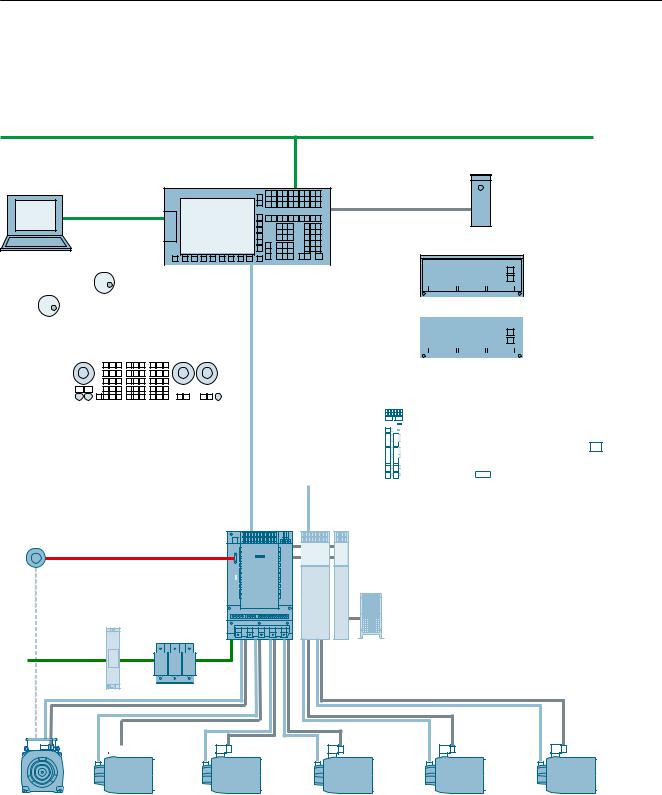

63, 5.5 Topology example with Safety Integrated functions Note Additional notes on Safety Integrated functions are available under: SINAMICS S120 Safety Integrated Function Manual. Topology with SINAMICS S120 booksize and six plus two axes 338 3DQHO 3URFHVVLQJ 8QLW 1; 1XPHULF &RQWURO ([WHQVLRQ $/0 $FWLYH /LQH 0RGXOH 600 6LQJOH 0RWRU 0RGXOH ’00 ‘RXEOH 0RWRU 0RGXOH 60[ 0RWRU HQFRGHU 70 7HUPLQDO 0RGXOH 60\ GLUHFW PHDVXULQ…

-

57, ● The sampling times (p0115[0] and p4099) of all components that are connected to a DRIVE- CLiQ line must be divisible by one another with an integer result. If the current controller sampling time on a DO has to be changed to another pattern that does not match the other DOs on the DRIVE-CLiQ line, the following options are available: – Reconnect the DO to a separate DRIVE-CLiQ line. – Als…

-

231, Note Tools for configuring and analyzing PROFINET components To configure and analyze PROFINET components, Siemens Automation and Drives Service & Support provides the following tools at no cost: ● Primary Setup Tool (PST) Using the Primary Setup Tool (PST), you can configure PROFINET components, e.g. you can allocate the PN/PN coupler a device name. You can find this tool in the Internet at the following address: (http:// support.automation.siemens.com/WW/view/en/19440…

-

157, 7.5.2 Mounting Dimensions of the mini handheld unit SLQ FRQQHFWRU :LWK VFUHZ FDS 0DJQHWLF FODPS 6WUDLJKW FDEOH +HOL[ FRQQHFWLQJ FDEOH Figure 7-32 Dimension drawing of the mini HHU Connectable components 7.5 Mini handheld unit PPU Manual, 01/2014, 6FC5397-2DP40-3BA3 157

… -

30, Siemens SINUMERIK 828D PPU Series ● Only use memory cards that have been approved by Siemens for use with SINUMERIK. Even though SINUMERIK follows general industry standards for memory cards, it is possible that memory cards from some manufacturers will not function perfectly in this device or are not completely compatible with it (you can obtain information on compatibility from the memory card manufacturer or supplier). ● For SINUMERIK 828D, only the memory card (2 GB) with order number 6FC5313-5AG00-0AA…

SINUMERIK

SINUMERIK 828D PPU

Manual

Preface

|

Safety notes |

1 |

|

System description |

2 |

|

Application planning |

3 |

|

Installing |

4 |

|

Rulesforpermittedtopologies |

5 |

|

Interface description |

6 |

|

Connectable components |

7 |

|

Technical data |

8 |

|

Spare parts and accessories |

9 |

|

Appendix |

A |

Valid for: SINUMERIK 828D PPU 24x.3 BASIC PPU 26x.3 PPU 28x.3

01/2014

6FC5397-2DP40-3BA3

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are graded according to the degree of danger.

indicates that death or severe personal injury will result if proper precautions are not taken.

indicates that death or severe personal injury may result if proper precautions are not taken.

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be used. A notice warning ofinjuryto persons with a safety alert symbol may also include a warning relating toproperty damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific taskinaccordancewiththerelevantdocumentation,inparticularitswarningnoticesandsafetyinstructions.Qualified personnel are those who, based on their training and experience, are capable of identifying risks and avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems. The permissible ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in this publication is reviewed regularly and any necessary corrections are included in subsequent editions.

|

Siemens AG |

Order number: 6FC5397-2DP40-3BA3 |

Copyright © Siemens AG 2009 — 2014. |

|

Industry Sector |

01/2014 Technical data subject to change |

All rights reserved |

|

Postfach 48 48 |

||

|

90026 NÜRNBERG |

||

|

GERMANY |

Preface

SINUMERIK documentation

The SINUMERIK documentation is organized into the following categories:

●General documentation

●User documentation

●Manufacturer/service documentation

Additional information

You can find information on the following topics under the link (www.siemens.com/ motioncontrol/docu):

●Ordering documentation / current documentation overview

●Additional links to download documents

●Using documentation online (finding and searching in manuals/information)

Please send any questions about the technical documentation (e.g. suggestions for improvement, corrections) to the following address: (mailto:docu.motioncontrol@siemens.com)

My Documentation Manager (MDM)

Under the following link you will find information to individually compile OEM-specific machine

documentation based on the Siemens content: MDM (www.siemens.com/mdm)

Training

For information about the range of training courses, refer to:

●SITRAIN (www.siemens.com/sitrain) — training courses from Siemens for automation products, systems and solutions

●SinuTrain (www.siemens.com/sinutrain) — training software for SINUMERIK

FAQs

You can find Frequently Asked Questions in the Service&Support pages under Product

Support (www.siemens.com/automation/service&support).

|

PPU |

3 |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

Preface

SINUMERIK

You can find information on SINUMERIK under the following link: (www.siemens.com/ sinumerik)

Target group

This documentation is intended for manufacturers of machine tools, particularly:

●Project engineers, electricians and installers

●Maintenance and service personnel

Benefits

The information in this manual facilitates installation and connection of the SINUMERIK 828D numerical control.

Standard version

This documentation only describes the functionality of the standard version. Extensions or changes made by the machine manufacturer are documented by the machine manufacturer.

Other functions not described in this documentation might be executable in the control. However, no claim can be made regarding the availability of these functions when the equipment is first supplied or in the event of servicing.

Further, for the sake of simplicity, this documentation does not contain all detailed information aboutalltypesoftheproductandcannotcovereveryconceivablecaseofinstallation,operation or maintenance.

Technical support

Country-specific telephone numbers for technical support are provided in the Internet under «Contact» (www.siemens.com/automation/service&support).

EC Declaration of Conformity

The EC declaration of conformity for the EMC directive can be found in the Internet (http:// support.automation.siemens.com/WW/view/de/10805517/134200).

|

4 |

PPU |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

Table of contents

|

Preface……………………………………………………………………………………………………………………………………… |

3 |

||

|

1 |

Safety notes……………………………………………………………………………………………………………………………….. |

9 |

|

|

1.1 |

Danger notices……………………………………………………………………………………………………………… |

9 |

|

|

1.2 |

ESD notices………………………………………………………………………………………………………………… |

11 |

|

|

2 |

System description……………………………………………………………………………………………………………………. |

13 |

|

|

2.1 |

Controller features……………………………………………………………………………………………………….. |

13 |

|

|

2.2 |

PPU version 24x.3 BASIC…………………………………………………………………………………………….. |

15 |

|

|

2.3 |

PPU versions 26x.3 and 28x.3………………………………………………………………………………………. |

18 |

|

|

2.4 |

Operator controls and display elements………………………………………………………………………….. |

21 |

|

|

2.5 |

Type plate…………………………………………………………………………………………………………………… |

22 |

|

|

2.6 |

System overview…………………………………………………………………………………………………………. |

24 |

|

|

2.7 |

Connectable components……………………………………………………………………………………………… |

26 |

|

|

2.8 |

Ordering data……………………………………………………………………………………………………………… |

27 |

|

|

2.9 |

CompactFlash Cards……………………………………………………………………………………………………. |

29 |

|

|

2.9.1 |

CompactFlash card system…………………………………………………………………………………………… |

29 |

|

|

2.9.2 |

Inserting the system CompactFlash Card……………………………………………………………………….. |

30 |

|

|

2.9.3 |

CompactFlash card for user data…………………………………………………………………………………… |

32 |

|

|

3 |

Application planning………………………………………………………………………………………………………………….. |

35 |

|

|

3.1 |

Secondary electrical conditions……………………………………………………………………………………… |

35 |

|

|

3.1.1 |

Protective Separation as per EN 61800-5-1…………………………………………………………………….. |

35 |

|

|

3.1.2 |

Grounding concept………………………………………………………………………………………………………. |

35 |

|

|

3.1.3 |

RI suppression measures……………………………………………………………………………………………… |

37 |

|

|

3.2 |

Climatic and mechanical environmental conditions…………………………………………………………… |

39 |

|

|

3.2.1 |

Ambient conditions………………………………………………………………………………………………………. |

39 |

|

|

3.2.2 |

Transport and Storage Conditions…………………………………………………………………………………. |

39 |

|

|

3.2.3 |

Operating Conditions……………………………………………………………………………………………………. |

40 |

|

|

3.3 |

Recycling and disposal…………………………………………………………………………………………………. |

41 |

|

|

4 |

Installing………………………………………………………………………………………………………………………………….. |

43 |

|

|

4.1 |

Mounting positions………………………………………………………………………………………………………. |

43 |

|

|

4.2 |

Dimension drawings…………………………………………………………………………………………………….. |

50 |

|

|

5 |

Rules for permitted topologies…………………………………………………………………………………………………….. |

53 |

|

|

5.1 |

Topology rules for S120 Combi……………………………………………………………………………………… |

53 |

|

|

5.2 |

Topology rules for S120 Booksize………………………………………………………………………………….. |

54 |

|

|

5.3 |

Topology rules for Safety Integrated functions…………………………………………………………………. |

58 |

|

PPU |

5 |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

Table of contents

|

5.4 |

Topology example without Safety Integrated functions……………………………………………………… |

59 |

|

|

5.5 |

Topology example with Safety Integrated functions………………………………………………………….. |

63 |

|

|

6 |

Interface description………………………………………………………………………………………………………………….. |

67 |

|

|

6.1 |

Interface overview……………………………………………………………………………………………………….. |

67 |

|

|

6.2 |

Power supply connection……………………………………………………………………………………………… |

69 |

|

|

6.2.1 |

Requirements for the power supply………………………………………………………………………………… |

69 |

|

|

6.2.2 |

Connecting the power supply………………………………………………………………………………………… |

71 |

|

|

6.3 |

Ethernet……………………………………………………………………………………………………………………… |

71 |

|

|

6.4 |

PLC I/O Interface based on PROFINET …………………………………………………………………………. |

73 |

|

|

6.4.1 |

Addressing the I/O modules………………………………………………………………………………………….. |

75 |

|

|

6.5 |

Digital inputs/outputs……………………………………………………………………………………………………. |

76 |

|

|

6.5.1 |

Terminal connection diagram………………………………………………………………………………………… |

81 |

|

|

6.5.2 |

Example: Connecting an inductive proximity switch (BEROs) …………………………………………. |

82 |

|

|

6.5.3 |

Technical data ……………………………………………………………………………………………………………. |

83 |

|

|

6.6 |

DRIVE-CLiQ……………………………………………………………………………………………………………….. |

84 |

|

|

6.6.1 |

DRIVE-CLiQ interface………………………………………………………………………………………………….. |

84 |

|

|

6.6.2 |

SINAMICS components……………………………………………………………………………………………….. |

86 |

|

|

6.7 |

Handwheel…………………………………………………………………………………………………………………. |

87 |

|

|

6.8 |

USB…………………………………………………………………………………………………………………………… |

89 |

|

|

6.9 |

RS 232 serial interface…………………………………………………………………………………………………. |

90 |

|

|

7 |

Connectable components…………………………………………………………………………………………………………… |

93 |

|

|

7.1 |

MCP 483C PN…………………………………………………………………………………………………………….. |

93 |

|

|

7.1.1 |

Operator controls and display elements………………………………………………………………………….. |

94 |

|

|

7.1.2 |

Mounting…………………………………………………………………………………………………………………….. |

97 |

|

|

7.1.3 |

Connecting…………………………………………………………………………………………………………………. |

98 |

|

|

7.1.4 |

Parameterization……………………………………………………………………………………………………….. |

104 |

|

|

7.1.5 |

Technical data…………………………………………………………………………………………………………… |

107 |

|

|

7.1.6 |

Spare parts and accessories……………………………………………………………………………………….. |

108 |

|

|

7.2 |

MCP 310C PN…………………………………………………………………………………………………………… |

111 |

|

|

7.2.1 |

Operator controls and display elements………………………………………………………………………… |

113 |

|

|

7.2.2 |

Mounting…………………………………………………………………………………………………………………… |

116 |

|

|

7.2.3 |

Connecting……………………………………………………………………………………………………………….. |

118 |

|

|

7.2.4 |

Parameterization……………………………………………………………………………………………………….. |

123 |

|

|

7.2.5 |

Technical data…………………………………………………………………………………………………………… |

126 |

|

|

7.2.6 |

Spare parts and accessories……………………………………………………………………………………….. |

127 |

|

|

7.3 |

MCP Interface PN……………………………………………………………………………………………………… |

130 |

|

|

7.3.1 |

Mounting…………………………………………………………………………………………………………………… |

133 |

|

|

7.3.2 |

Connection……………………………………………………………………………………………………………….. |

134 |

|

|

7.3.3 |

Parameter assignment……………………………………………………………………………………………….. |

146 |

|

|

7.3.4 |

Technical data…………………………………………………………………………………………………………… |

148 |

|

|

7.4 |

Electronic handwheel…………………………………………………………………………………………………. |

148 |

|

|

7.4.1 |

Description……………………………………………………………………………………………………………….. |

148 |

|

|

7.4.2 |

Mounting…………………………………………………………………………………………………………………… |

151 |

|

|

7.4.3 |

Connection……………………………………………………………………………………………………………….. |

152 |

|

6 |

PPU |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

|

Table of contents |

|||

|

7.4.4 |

Technical specifications……………………………………………………………………………………………… |

153 |

|

|

7.4.5 |

Spare parts and accessories……………………………………………………………………………………….. |

154 |

|

|

7.5 |

Mini handheld unit……………………………………………………………………………………………………… |

154 |

|

|

7.5.1 |

Description……………………………………………………………………………………………………………….. |

154 |

|

|

7.5.2 |

Mounting…………………………………………………………………………………………………………………… |

157 |

|

|

7.5.3 |

Connecting……………………………………………………………………………………………………………….. |

160 |

|

|

7.5.4 |

Parameterization……………………………………………………………………………………………………….. |

162 |

|

|

7.5.5 |

Technical data ………………………………………………………………………………………………………….. |

163 |

|

|

7.5.6 |

Spare parts and accessories……………………………………………………………………………………….. |

164 |

|

|

7.6 |

PP 72/48D PN…………………………………………………………………………………………………………… |

166 |

|

|

7.6.1 |

Description……………………………………………………………………………………………………………….. |

166 |

|

|

7.6.2 |

Mounting…………………………………………………………………………………………………………………… |

169 |

|

|

7.6.3 |

Connecting……………………………………………………………………………………………………………….. |

171 |

|

|

7.6.3.1 |

X1 power supply………………………………………………………………………………………………………… |

172 |

|

|

7.6.3.2 |

X2 PROFINET…………………………………………………………………………………………………………… |

173 |

|

|

7.6.3.3 |

X111, X222 and X333 pin assignment………………………………………………………………………….. |

174 |

|

|

7.6.3.4 |

Specification of the digital inputs………………………………………………………………………………….. |

177 |

|

|

7.6.3.5 |

Specification of the digital outputs………………………………………………………………………………… |

178 |

|

|

7.6.4 |

Parameter assignment……………………………………………………………………………………………….. |

179 |

|

|

7.6.4.1 |

Input / output images………………………………………………………………………………………………….. |

179 |

|

|

7.6.4.2 |

Diagnostics via input image…………………………………………………………………………………………. |

181 |

|

|

7.6.5 |

Technical data…………………………………………………………………………………………………………… |

183 |

|

|

7.7 |

PP 72/48D 2/2A PN……………………………………………………………………………………………………. |

184 |

|

|

7.7.1 |

Description……………………………………………………………………………………………………………….. |

184 |

|

|

7.7.2 |

Assembling……………………………………………………………………………………………………………….. |

187 |

|

|

7.7.3 |

Connection……………………………………………………………………………………………………………….. |

189 |

|

|

7.7.3.1 |

X1 power supply………………………………………………………………………………………………………… |

190 |

|

|

7.7.3.2 |

X2 PROFINET…………………………………………………………………………………………………………… |

193 |

|

|

7.7.3.3 |

X111, X222 and X333 pin assignment………………………………………………………………………….. |

194 |

|

|

7.7.3.4 |

Specification of the digital inputs………………………………………………………………………………….. |

197 |

|

|

7.7.3.5 |

Specification of the digital outputs………………………………………………………………………………… |

198 |

|

|

7.7.3.6 |

Analog X3 inputs/outputs……………………………………………………………………………………………. |

199 |

|

|

7.7.4 |

Assigning parameters…………………………………………………………………………………………………. |

203 |

|

|

7.7.4.1 |

Input / output images………………………………………………………………………………………………….. |

203 |

|

|

7.7.4.2 |

Diagnostics via input image…………………………………………………………………………………………. |

205 |

|

|

7.7.4.3 |

Assigning parameters to the analog inputs / outputs………………………………………………………. |

207 |

|

|

7.7.4.4 |

Analog value representation………………………………………………………………………………………… |

209 |

|

|

7.7.4.5 |

Examples………………………………………………………………………………………………………………….. |

212 |

|

|

7.7.5 |

Technical data…………………………………………………………………………………………………………… |

213 |

|

|

7.8 |

NX10.3…………………………………………………………………………………………………………………….. |

214 |

|

|

7.8.1 |

Description……………………………………………………………………………………………………………….. |

214 |

|

|

7.8.2 |

Mounting…………………………………………………………………………………………………………………… |

217 |

|

|

7.8.3 |

Connecting……………………………………………………………………………………………………………….. |

219 |

|

|

7.8.4 |

Technical Data………………………………………………………………………………………………………….. |

223 |

|

|

8 |

Technical data………………………………………………………………………………………………………………………… |

225 |

|

|

9 |

Spare parts and accessories…………………………………………………………………………………………………….. |

227 |

|

|

9.1 |

SINAUT modem………………………………………………………………………………………………………… |

227 |

|

|

9.2 |

PN/PN coupler…………………………………………………………………………………………………………… |

229 |

|

PPU |

7 |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

Table of contents

|

9.2.1 |

Principle of operation ………………………………………………………………………………………………….. |

229 |

|

|

9.2.2 |

Configuration …………………………………………………………………………………………………………….. |

230 |

|

|

9.3 |

SENTRON PAC3200/PAC4200 …………………………………………………………………………………… |

233 |

|

|

9.4 |

SITOP power supply ………………………………………………………………………………………………….. |

235 |

|

|

9.5 |

Terminal strip converter ………………………………………………………………………………………………. |

236 |

|

|

A |

Appendix |

………………………………………………………………………………………………………………………………… |

237 |

|

A.1 |

Abbreviations …………………………………………………………………………………………………………….. |

237 |

|

|

A.2 …………………………………………………………………. |

Documentation overview SINUMERIK 828D |

239 |

|

|

Index……………………………………………………………………………………………………………………………………… |

241 |

|

8 |

PPU |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

1.1Danger notices

The following notices are intended firstly for your personal safety and secondly to prevent damage occurring to the product described or any connected devices and machines. Nonobservance of the warnings can result in severe personal injury or property damage.

Qualified personnel

Only appropriately qualified personnel may commission/start-up SINUMERIK equipment.

The personnel must take into account the information provided in the technical customer documentation for the product, and be familiar with and observe the specified danger and warning notices.

When electrical equipment and motors are operated, the electrical circuits automatically conduct a dangerous voltage.

When the system is operating, dangerous axis movements may occur throughout the entire work area.

A potential fire hazard exists due to the energy being transferred in the equipment and the work materials used.

All work on the electrical system must be performed after the system has been switched off and disconnected from the power supply.

Supply voltage

External power supply units for supplying components of the drive control must have safety isolation from circuits with dangerous voltages (DVC A according to EN 61800-5-1; SELV/ PELV).Inadditiononlypowerunitswithcontrolcircuitsthathavesafetyisolationfromcircuits with dangerous voltages may be connected.

|

PPU |

9 |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

Safety notes

1.1 Danger notices

Commissioning and operation of the devices

Proper transportation, expert storage, installation and mounting, as well as careful operation and maintenance are essential for this SINUMERIK device to operate correctly and reliably.

The details in the catalogs and proposals also apply to the design of special equipment versions.

In addition to the danger and warning information provided in the technical customer documentation, the applicable national, local, and system-specific regulations and requirements must be taken into account.

Only class DVC A protective extra-low voltages (PELVs) may be connected to connections and terminals up to 60 V DC in accordance with EN 61800-5-1.

Should it be necessary to test or take measurements on live equipment, then the specifications and procedural instructions defined in Accident Prevention Regulation BGV A2 must be adhered to, in particular § 8 «Permissible deviations when working on live components». Suitable electric tools should be used.

Carrying out of repairs

Repairs to devices that we have supplied may only be carried out by Siemens Customer Service or by repair centers authorized by Siemens.

When replacing parts or components, only use those parts that are included in the spare parts list.

EMERGENCY STOP/EMERGENCY OFF devices according to EN 60204-1 (VDE 0113 Part 1)mustremainactiveinallmodesoftheautomationequipment.ResettingtheEMERGENCY STOP/EMERGENCY OFF device must not cause an uncontrolled or undefined restart.

Anywhere in the automation equipment where faults might cause physical injury or major material damage, in other words, where faults could be dangerous, additional external precautions must be taken, or facilities must be provided, that guarantee or enforce a safe operational state, even when there is a fault (e.g. using an independent limit value switch, mechanical locking mechanisms, EMERGENCY STOP/EMERGENCY OFF devices).

|

10 |

PPU |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

Safety notes

1.2 ESD notices

1.2ESD notices

NOTICE

Handling ESD modules:

The modules contain electrostatically sensitive devices. Discharge yourself of electrostatic energy before touching the components. The easiest way to do this is to touch a conductive, grounded object immediately beforehand (for example, bare metal parts of control cabinet or the protective ground contact of a socket outlet).

●When handling electrostatically sensitive devices, make sure that operator, workplace and packing material are properly grounded.

●Generally, electronic modules must not be touched unless work has to be carried out on them. When handling PC boards make absolutely sure that you do not touch component pins or printed conductors.

●Touch components only if:

–you are constantly grounded via an ESD arm band,

–ESD shoes or ESD shoe grounding strips if there is an ESD floor.

●Boards/modules must only be placed on conductive surfaces (table with ESD surface, conductive ESD foam, ESD packaging, ESD transport container).

●Keep modules away from visual display units, monitors or TV sets (minimum distance from screen 10 cm).

●Do not bring ESD-sensitive modules into contact with chargeable and highly-insulating materials, such as plastic, insulating table tops or clothing made of synthetic materials.

●Measurements on modules are allowed only if:

–The measuring instrument is properly earthed (e.g., protective conductor) or

–Beforemeasuringwithafloatingmeasuringinstrument,theprobeisbrieflydischarged (e.g., touch the bare metal parts of the control housing).

|

PPU |

11 |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

System description |

2 |

2.1Controller features

Features

The SINUMERIK 828D is a tailor-made CNC solution for milling and turning machines in the medium performance range.

SINUMERIK828Disapanel-basedCNC(panelprocessingunit).ACNC,PLC,operatorpanel and axis control for six drives (standard) are combined in a single unit. This design provides a high degree of robustness by eliminating the need for hardware interfaces between the CNC electronics board and the operator panel. In order to guarantee that operation is as lowmaintenance as possible, there are no wearing parts such as fans or back-up batteries.

●CNC operator panel with tailor-made system software versions for turning and milling technologies. PPU 28x, PPU 26x and PPU 24x BASIC

●Two operator panel versions for horizontal and vertical operator panel housings.

●Integrated full QWERTY CNC keyboard with mechanical short-stroke keys.

This enables the user to enter text for part-program names or tool identifiers and plain-text language commands directly, without using the keys of the second input level (shift key). The keys have IP65 degree of protection.

●USB, CompactFlash card and Ethernet interface on the operator panel front.

●Additional Ethernet interface on the rear of the CNC for a permanent factory network.

●PLC I/O Interface based on PROFINET for the connection of PLC I/O devices and a machine control panel.

●PP 72/48D PN and PP 72/48D 2/2A PN as PLC I/O module.

●Three handwheels can be connected.

●Optional GSM modem connection possible.

●Up to six axes/spindles for milling applications and up to eight axes/spindles for turning applications.

●One machining channel / mode group.

●IntegratedPLCbasedontheSIMATICS7-200commandsetwithladderlogicprogramming.

●Standardized 3/8″ threads are embedded in the upper edges of the operator panel. These threads can be used for attaching commercially available additional components such as holders for diagrams or similar.

Control system versions

The SINUMERIK 828D is available in different versions (horizontal or vertical; turning or milling).

The SINUMERIK 828D is available in the following versions:

|

PPU |

13 |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

System description

2.1Controller features

●PPU 240.3 BASIC (vertical operator panel)

●PPU 241.3 BASIC (horizontal operator panel)

●PPU 260.3 (vertical operator panel)

●PPU 261.3 (horizontal operator panel)

●PPU 280.3 (vertical operator panel)

●PPU 281.3 (horizontal operator panel)

Quantity structure

The following table shows the quantity structures for the different control versions:

|

Function |

PPU 240.3 / 241.3 |

PPU 260.3 / 261.3 |

PPU 280.3 / 281.3 |

||||

|

BASIC |

|||||||

|

Turning |

Milling |

Turning |

Milling |

Turning |

Milling |

||

|

Non-volatile memory (NVRAM): |

|||||||

|

● |

For OEM data |

512 KB |

512 KB |

512 KB |

512 KB |

512 kB |

512 kB |

|

● |

For user data |

3 MB |

3 MB |

5 MB |

5 MB |

8 MB |

8 MB |

|

Number of axes/spindles |

3 |

4 |

3 |

4 |

3 |

4 |

|

|

Maximum number of axes/spindles |

5 |

5 |

6 |

6 |

6 / 8 * |

6 |

|

|

Maximum number of axes with drive- |

5 |

5 |

6 |

6 |

6 / 8 * |

6 |

|

|

based Safety Integrated |

|||||||

|

Axis expansion with NX10.3 |

— |

— |

— |

1 |

1 |

1 |

|

|

Number of DRIVE-CLiQ interfaces |

3 |

3 |

3 |

3 |

3 |

3 |

|

|

Maximum number of I/O modules |

3 |

3 |

4 |

4 |

5 |

5 |

|

|

(digital/analog) |

Note

Axis extensions for PPU 28x.3

With the help of a NX10.3, the following extensions can be connected:

●The maximum number of axes can be increased to eight, six of which can be connected to the PPU and two to the NX10.3.

●One high-speed spindle (e.g. 24,000 rpm with four pole pairs) can be connected to the NX10.3 and five axes to the PPU.

|

14 |

PPU |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

System description

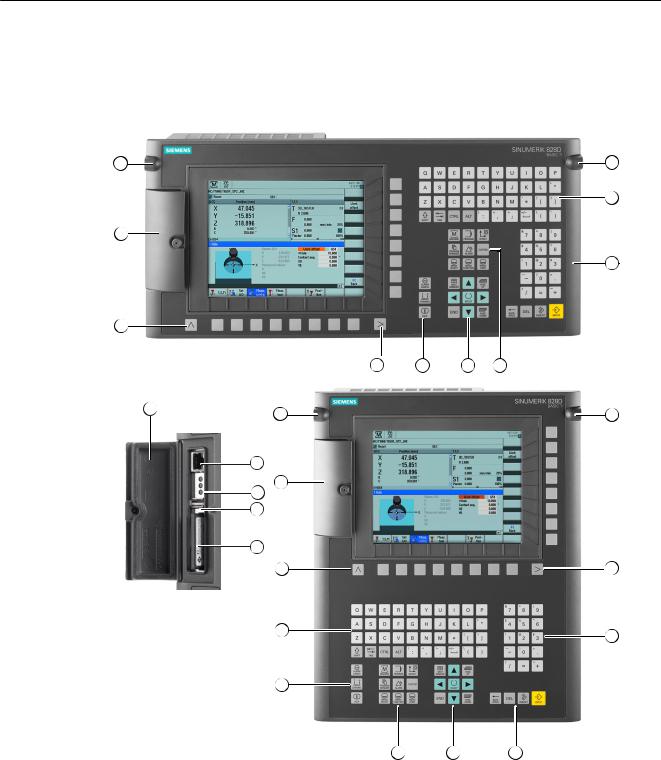

2.2 PPU version 24x.3 BASIC

2.2PPU version 24x.3 BASIC

Front side of the PPU 24x.3 BASIC

|

PPU |

15 |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

System description

2.2 PPU version 24x.3 BASIC

Front cover Menu back key

Alphabetic key group Control key group Hotkey group Cursor key group Numerical block Menu forward key

3/8″ threads for additional components X127 Ethernet (service socket)

Status LED: RDY, NC, CF X125 USB interface

Slot for CompactFlash card with user data

Figure 2-1 System versions

|

16 |

PPU |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

System description

2.2 PPU version 24x.3 BASIC

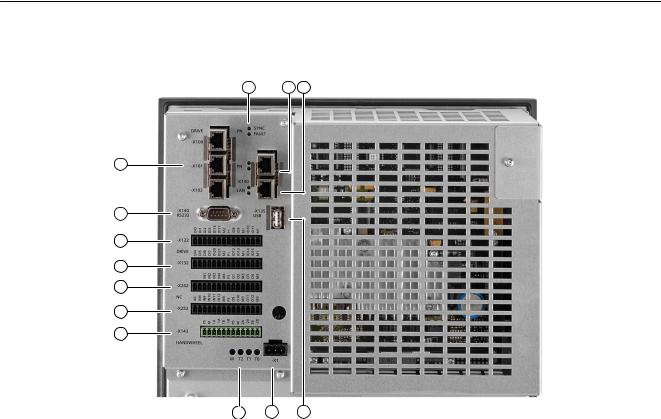

Rear side of the PPU 24x.3 BASIC

|

X122, X132 |

Digital inputs/outputs, drive |

|

|

X242, X252 |

Digital inputs/outputs for NC; controller of the analog spindle (X252) |

|

|

X143 |

Handwheels |

|

|

M, T2, T1, T0 |

Measuring sockets |

|

|

X1 |

Power supply |

|

|

X135 |

USB interface: For service purposes only |

|

|

X130 |

Ethernet LAN |

|

|

PN |

PLC I/O Interface |

|

|

SYNC, FAULT |

Status LEDs |

X100, X101, X102 DRIVE-CLiQ interfaces

|

X140 |

Serial interface RS232 |

Figure 2-2 Interfaces at the rear

|

PPU |

17 |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

System description

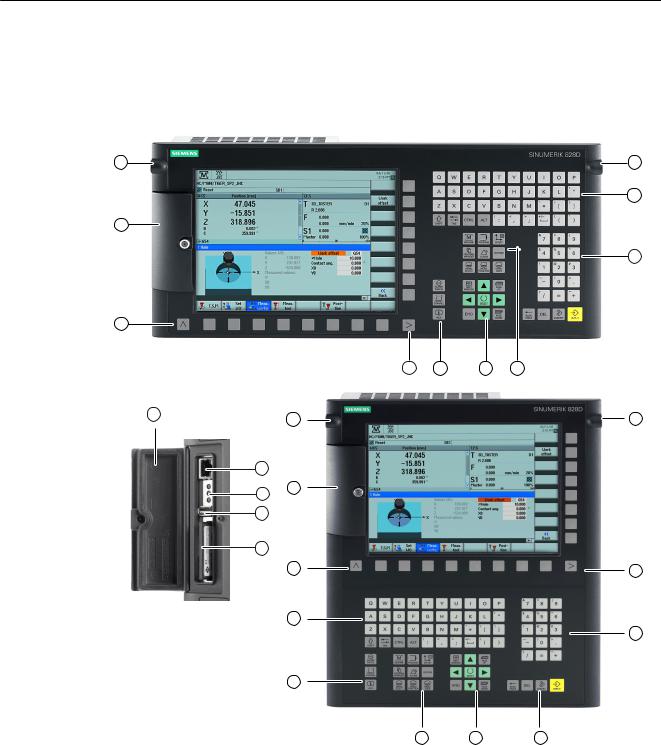

2.3 PPU versions 26x.3 and 28x.3

2.3PPU versions 26x.3 and 28x.3

Front of the PPU versions 26x.3 and 28x.3

|

18 |

PPU |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

System description

2.3 PPU versions 26x.3 and 28x.3

Front cover Menu back key

Alphabetic key group Control key group Hotkey group Cursor key group Numerical block Menu forward key

3/8″ threads for additional components Front cover

X127 Ethernet (service socket) Status LED: RDY, NC, CF

X125 USB interface

Slot for CompactFlash card with user data

Figure 2-3 System versions

|

PPU |

19 |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

System description

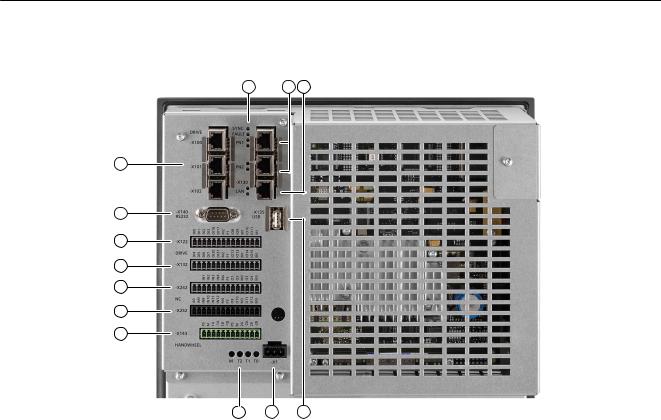

2.3 PPU versions 26x.3 and 28x.3

Rear of the PPU versions 26x.3 and 28x.3

|

X122, X132 |

Digital inputs/outputs, drive |

|

X242, X252 |

Digital inputs/outputs for NC; controller of the analog spindle (X252) |

|

X143 |

Handwheels |

|

M, T2, T1, T0 |

Measuring sockets |

|

X1 |

Power supply |

|

X135 |

USB interface: For service purposes only |

|

X130 |

Ethernet LAN |

|

PN 1, PN 2 |

PLC I/O Interface |

|

SYNC, FAULT |

Status LEDs |

|

X100, X101, X102 |

DRIVE-CLiQ interfaces |

|

X140 |

Serial interface RS232 |

Figure 2-4 Interfaces at the rear of the PPU

|

20 |

PPU |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

System description

2.4 Operator controls and display elements

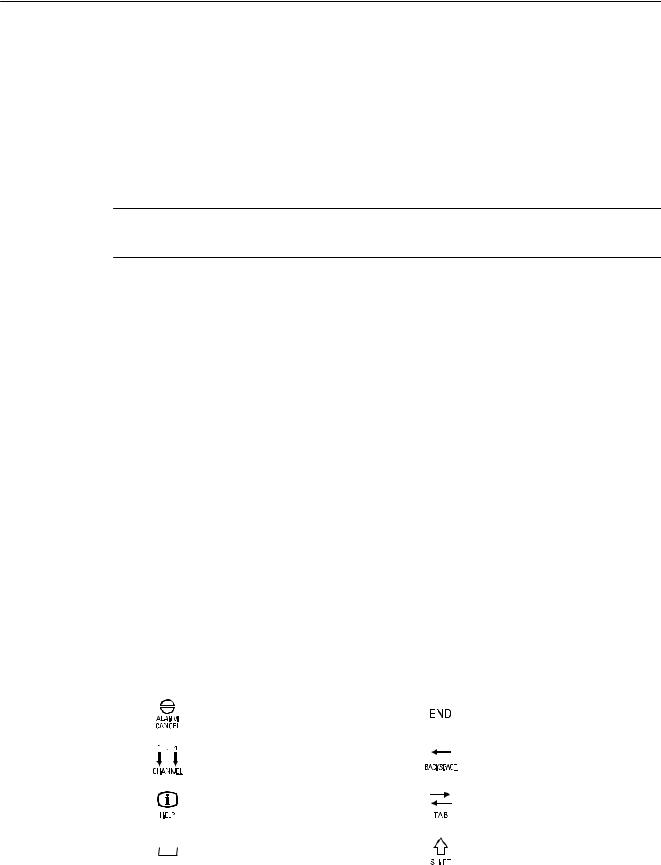

2.4Operator controls and display elements

TFT color display

The TFT color display has a diagonal size of 10.4″ (PPU 26x.3/28x.3) or 8.4″ (PPU 24x.3). The resolution is 800 x 600 pixels. The softkeys are arranged in an 8 + 8 layout; this makes the CNC easy to operate using only a very small number of menu levels.

Note

Pixel error acc. to DIN EN ISO 13406-2 Class II.

Keyboard

Several keys and key pads are installed on the operator panel front:

●The alphabetic key group contains the letters A … Z and the space character for entering text.

●The numeric key group contains the digits 0 — 9, arithmetic/special characters and the decimal point for entering numeric characters and operators.

●The cursor key group is used to navigate on the screen.

●The control key group includes special functions.

●The area changeover displays the operating areas.

●The menu forward key allows the horizontal softkey bar to be extended in the same menu.

●The softkeys call up functions that are available on screen via a menu bar.

●The machine area key switches directly into the «Machine» operating area.

●The menu back key returns to the superordinate menu, one window is closed.

The keys used on the operator panel front along with the corresponding function keys on the PC keyboard are shown in the following overview:

|

Key |

Function corresponds to PC |

Key |

Function corresponds to PC |

||||||||||||

|

key function |

key function |

||||||||||||||

|

Esc |

End |

||||||||||||||

|

F11 |

Backspace |

||||||||||||||

|

F12 |

Tabulator |

||||||||||||||

|

Spaces |

(only for internal keyboard |

||||||||||||||

|

changeover) |

|||||||||||||||

|

PPU |

21 |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

System description

2.5 Type plate

|

Key |

Function corresponds to PC |

Key |

Function corresponds to PC |

|||||||||||||

|

key function |

key function |

|||||||||||||||

|

Home |

CTRL key |

|||||||||||||||

|

Page up |

ALT key |

|||||||||||||||

|

Page down |

Delete |

|||||||||||||||

|

Cursor up |

Insert |

|||||||||||||||

|

Cursor left |

Enter |

|||||||||||||||

|

Cursor right |

F9 |

|||||||||||||||

|

Cursor down |

F10 |

|||||||||||||||

|

5 (in numeric key group) |

A … Z |

A … Z |

||||||||||||||

|

<Shift> F9 |

<Shift> F10 |

|||||||||||||||

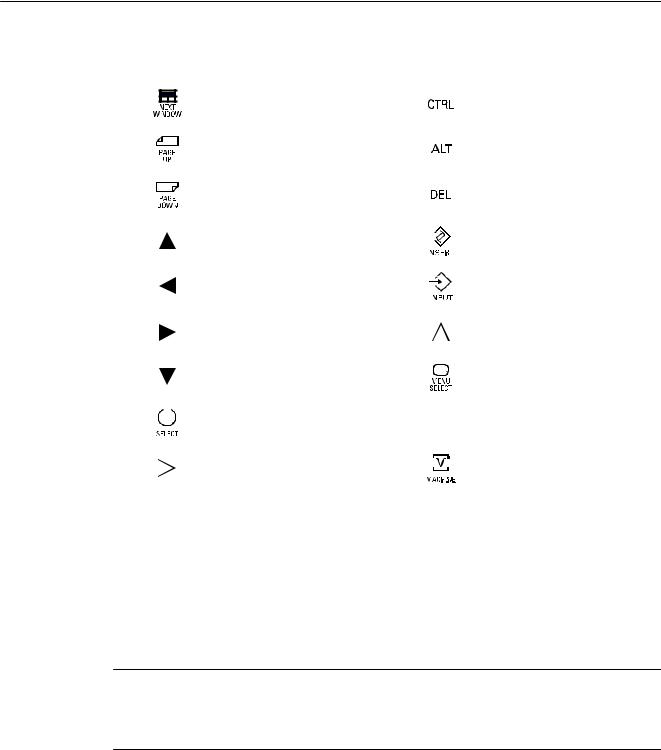

2.5Type plate

Type plates

The PPU type plate is located on the rear side.

Note

The contents of the individual type plate fields on the current controller may differ from those described in this Manual (e.g. updated product status, approvals and identifications not yet issued, etc.).

The following images display all the information required to uniquely identify a PPU.

|

22 |

PPU |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

System description

2.5 Type plate

|

$UWLFO QXP |

U |

|

|

6 UL O QXP |

U |

|

|

,’ QXP |

U |

+: Y UVLRQ

Figure 2-5 Horizontal PPU type plate

|

&RPSRQ QW Q P |

||||

|

$UWLFO QXP |

U |

|||

|

6 UL O QXP |

U |

|||

|

,’ QXP |

U |

Figure 2-6 Vertical PPU type plate

Note

MAC addresses

The MAC addresses printed on the type plate of the PPU are required for configuring the PLC I/O Interface communications networks based on PROFINET and Industrial Ethernet.

There is a similar situation for the machine control panels and the I/O modules.

|

PPU |

23 |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

System description

2.6 System overview

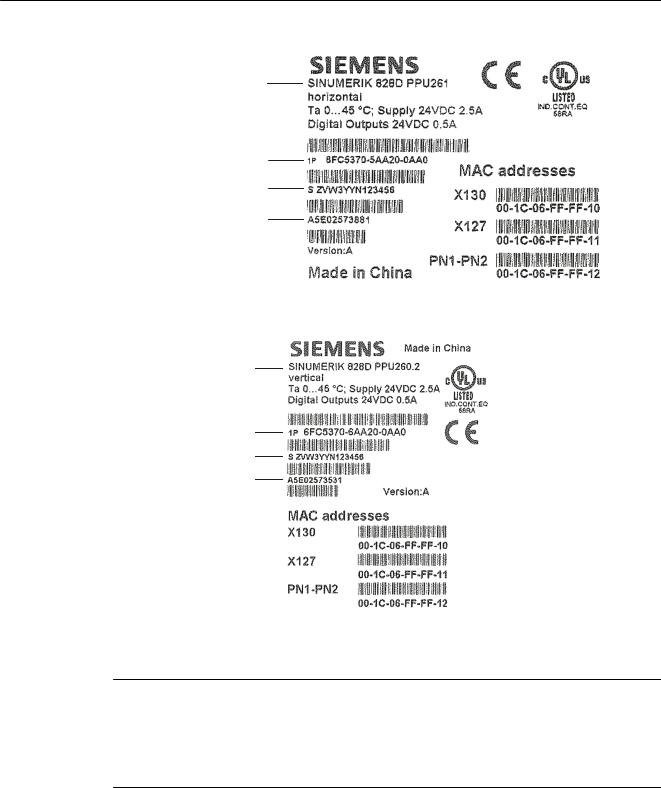

2.6System overview

Configuration with four axes (basic configuration)

The following configuration shows a typical example with SINAMICS S120 booksize:

&RPS Q\ QHWZRUN ,QGXVWUL O (W HUQHW

|

6,180(5,. ‘ |

||||||||||||||||||||||||||||||

|

3HHU WR SHHU |

||||||||||||||||||||||||||||||

|

1XOO PRGHP |

||||||||||||||||||||||||||||||

|

F OH |

||||||||||||||||||||||||||||||

|

6,1$87 0′ |

||||||||||||||||||||||||||||||

|

3* 3& |

||||||||||||||||||||||||||||||

|

‘5,9( &/L4 |

||||||||||||||||||||||||||||||

|

3/& , 2 LQWHUI FH VHG |

||||||||||||||||||||||||||||||

|

[ QGZ HHO |

RQ 352),1(7 |

6,1$0,&6 6 |

||||||||||||||||||||||||||||

0&3 31

60&

|

6/0 |

600 |

600 |

600 |

600 |

|||||||||

33 ‘ 31

6\QF URQRXV

|

33 ‘ $ 31 |

6\QF URQRXV PRWRU |

||

|

$V\QF URQRXV PRWRU |

|||

6\QF URQRXV PRWRU

Figure 2-7 Configuration example 1: Basic configuration with four axes

|

24 |

PPU |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

System description

2.6 System overview

Configuration with S120 Combi and six axes

The following configuration shows the maximum expansion stage with SINAMICS S120 Combi:

&RPS Q\ QHWZRUN ,QGXVWUL O (WKHUQHW

6,180(5,. ‘

1XOO PRGHP F OH

3HHU WR SHHU

3* 3&

|

33 ‘ 31 |

|||||||||||||||||||||||||||||||

|

[ K QGZKHHO |

|||||||||||||||||||||||||||||||

|

3/& , 2 LQWHUI FH VHG |

|||||||||||||||||||||||||||||||

|

RQ 352),1(7 |

|||||||||||||||||||||||||||||||

|

33 ‘ $ 31 |

|||||||||||||||||||||||||||||||

|

70 ) |

|||||||||||||||||||||||||||||||

|

‘0& ‘0( |

8S WR ILYH |

||||||||||||||||||||||||||||||

|

0&3 31 |

|||||||||||||||||||||||||||||||

|

‘5,9( &/L4 |

/LQH U VF OHV |

||||||||||||||||||||||||||||||

|

6,1$0,&6 |

|||

|

77/ VSLQGOH HQFRGHU |

6 &RP L |

♣ ‘RX OH 0RWRU 0RGXOH %RRNVL]H &RPS FW |

|

|

3RZHU 0RGXOH |

♣ &RQWURO 6XSSO\ 0RGXOH |

||

|

♣ %U NLQJ 0 RGXOH %U NLQJ UHVLVWRU |

|||

|

2SWLRQ |

O |

||

|

/LQH ILOWHU |

/LQH UH FWRU |

||

$& 9

0RWRU F OH

‘5,9( &/L4

|

6SLQGOH PRWRU |

6HUYR PRWRU |

6HUYR PRWRU |

6HUYR PRWRU |

6HUYR PRWRU |

6HUYR PRWRU |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

6XSSOHPHQW |

U\ |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

VSLQGOH |

Figure 2-8 Configuration example 2: Maximum expansion stage with six axes and with Safety Integrated

|

PPU |

25 |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

System description

2.7 Connectable components

2.7Connectable components

Component overview

The following components can be connected to the PPU:

●Machine Control Panel MCP 310C PN, MCP 483C PN

Contains the keys and switches required for the operation of a machine (turning or milling machine).

●Interface module MCP Interface PN

The MCP Interface PN module enables customer-specific machine control panels to be connected. Further, a 3rd handwheel can be connected via the module.

●Handwheels

A maximum of three handwheels can be connected.

●Mini handheld unit

A mini HHU can be integrated into the SINUMERIK 828D system using a connection kit.

●I/O modules PP 72/48D PN / PP 72/48D 2/2A PN

The modules are used to connect digital as well as analog inputs and outputs. To supply the module and the outputs, an external power supply unit (24 VDC) is required, which provides safety isolation from dangerous voltages.

●GSM modem

ConnectionofaSINAUTMD720-3GSMmodemforsendingandreceivingSMSmessages (Easy Message) via the serial RS232 interface.

●PN/PN coupler

A PN/PN coupler can be connected in order to link a SINUMERIK 828D to PROFINET networks.

●SENTRON PAC 3200/PAC 4200

The connection of a SENTRON PAC 3200 / PAC 4200 makes available functions for increasing the energy efficiency of machine tools.

SINAMICS S120 drive system

Only the SINAMICS S120 Line Modules and Motor Modules are used for drive control. Motor Modules can be used to connect servo motors as type 1FK7, 1FT7, and 1PH8 feed and main spindle motors. Type 1FW6 torque motors can also be connected.

See also

Connectable components (Page 93)

SINAMICS components (Page 86)

●Rules for permitted topologies (Page 53)

●Interface description (Page 67)

|

26 |

PPU |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

System description

2.8 Ordering data

2.8Ordering data

Ordering data of the components

SINUMERIK 828D is generally marketed in sales packages with drives, motors and accessories. For orders, please contact your local Siemens sales representative.

|

Table 2-1 |

Components |

||

|

Designation |

Article number |

||

|

Panel Processing Unit without system software |

|||

|

● PPU 241.3 BASIC horizontal |

6FC5370-3AA30-0AA0 |

||

|

● PPU 240.3 BASIC vertical |

6FC5370-4AA30-0AA0 |

||

|

● |

PPU 261.3 horizontal |

6FC5370-5AA30-0AA0 |

|

|

● |

PPU 260.3 vertical |

6FC5370-6AA30-0AA0 |

|

|

● |

PPU 281.3 horizontal |

6FC5370-7AA30-0AA0 |

|

|

● |

PPU 280.3 vertical |

6FC5370-8AA30-0AA0 |

|

|

CompactFlash card with system software and license |

|||

|

● For PPU 241.3 / PPU 240.3: Turning |

6FC5835-1GY40- YA0 |

||

|

● For PPU 241.3 / PPU 240.3: Milling |

6FC5835-2GY40- YA0 |

||

|

● For PPU 261.3 / PPU 260.3: Turning |

6FC5834-1GY40- YA0 |

||

|

● For PPU 261.3 / PPU 260.3: Milling |

6FC5834-2GY40- YA0 |

||

|

● For PPU 281.3 / PPU 280.3: Turning |

6FC5833-1GY40- YA0 |

||

|

● For PPU 281.3 / PPU 280.3: Milling |

6FC5833-2GY40- YA0 |

||

|

Axis extension: |

|||

|

● Numeric Control Extension NX10.3 |

6SL3040-1NC00-0AA0 |

||

|

Machine control panels: |

|||

|

● |

MCP 483C PN |

6FC5303-0AF22-0AA1 |

|

|

● |

MCP 310C PN |

6FC5303-0AF23-0AA1 |

|

|

Interface module |

|||

|

● |

MCP Interface PN |

6FC5303-0AF03-0AA0 |

|

|

Mini handheld unit: |

|||

|

● With spiral connection cable |

6FX2007-1AD03 |

||

|

● |

With straight cable |

6FX2007-1AD13 |

|

|

I/O modules: |

|||

|

● PP 72/48D PN (digital) |

6FC5311-0AA00-0AA0 |

||

|

● PP 72/48D 2/2A PN (analog) |

6FC5311-0AA00-1AA0 |

|

PPU |

27 |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

System description

2.8 Ordering data

Spare parts

|

Table 2-2 |

Spare parts |

|

|

Designation |

Article number |

|

|

Set of tensioners (9 units) |

6FC5248-0AF14-0AA0 |

|

|

CompactFlash card (empty), 2 GB |

6FC5313-5AG00-0AA2 |

|

|

Front flap with fastening |

6FC5348-2AA00-0AA0 |

Accessories

|

Table 2-3 |

Accessories |

|

|

Designation |

Article number |

|

|

SENTRON PAC3200 Power Monitoring Device |

7KM2112-0BA00-3AA0 |

|

|

SENTRON PAC4200 Power Monitoring Device |

7KM4212-0BA00-3AA0 |

|

|

PROFINET Switched Ethernet expansion module |

7KM9300-0AE00-0AA0 |

|

|

SINAUT MD720-3 GSM/GPRS MODEM |

6NH9720-3AA00 |

|

|

SINAUT ANT 794-4MR ANTENNA |

6NH9860-1AA00 |

|

|

RS232 modem cable |

6NH7701-5AN |

|

|

SIMATIC DP PN/PN coupler |

6ES7158-3AD00-0XA0 |

|

|

Terminal strip converter, 50-pin |

6EP5406-5AA00 |

|

|

Cable set comprising: |

6EP5306-5BG00 |

|

|

● 6 m ribbon cable, 50-pin |

||

|

● 8 insulation displacement connectors, 50-pin |

||

|

IP20 PLC I/O interface connecting cable (corresponds to |

6FX2002-1DC00-… |

|

|

DRIVE-CLiQ signal cable) |

||

|

Blanking plates for the DRIVE-CLiQ interface |

6SL3066-4CA00-0AA0 |

|

|

USB flash drive, 8 GB |

6ES7648-0DC50-0AA0 |

|

|

CompactFlash card (empty as user memory), 8 GB |

6FC5313-6AG00-0AA0 |

|

|

Stabilized power supply SITOP lite 10 A |

6EP1334-1LB00 |

|

|

24 VDC, 1-phase |

||

|

Stabilized power supply SITOP smart 10 A |

6EP1334-2BA01 |

|

|

24 VDC, 1-phase |

||

|

Stabilized power supply PSU100S 20 A |

6EP1336-2BA10 |

|

|

24 VDC, 1-phase |

||

|

Stabilized power supply PSU300S 10 A |

6EP1434-2BA10 |

|

|

24 VDC, 3-phase |

||

|

Stabilized power supply PSU300S 20 A |

6EP1436-2BA10 |

|

|

24 VDC, 3-phase |

|

28 |

PPU |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

System description

2.9 CompactFlash Cards

2.9CompactFlash Cards

2.9.1CompactFlash card system

Overview

The PPU has two slots for CompactFlash cards:

●The slot for the user CompactFlash card is located at the front behind the front flap.

●The slot for the system CompactFlash card with the system software is at the rear.

CompactFlash card with system software

The system CompactFlash card is shipped in a bootable condition. It is not supplied with the PPU and must be ordered as a separate component.

The system CompactFlash card is essential for the operation of the PPU.

In addition to the technology-specific system software for SINUMERIK 828D and the firmware for SINAMICS, the system CompactFlash card also contains:

●Version information (serial number, version, type designation)

●Licensekey:AllowstheCompactFlashcardtobeinsertedintoanotherPPUwithouthaving to change the licenses.

Note the following when using a system CompactFlash card:

●SINUMERIK CNC supports the file systems FAT16 and FAT32 for CompactFlash cards. You may need to format the memory card if you want to use a memory card from another device or if you want to ensure the compatibility of the memory card with the SINUMERIK. However, formatting the memory card will permanently delete all data on it.

●Do not remove the memory card while it is being accessed. This can lead to damage of the memory card and the SINUMERIK as well as the data on the memory card.

●If you cannot use a memory card with the SINUMERIK, it is probably because the memory card is not formatted for the control system (e.g. Ext3 Linux file system), the memory card file system is faulty or it is the wrong type of memory card.

●Insertthememorycardcarefullyandtherightwayroundintothememorycardslot(observe indicatorssuchasarroworsimilar).Thiswayyouavoidmechanicaldamagetothememory card or the device.

|

PPU |

29 |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

System description

2.9CompactFlash Cards

●Only use memory cards that have been approved by Siemens for use with SINUMERIK. Even though SINUMERIK follows general industry standards for memory cards, it is possible that memory cards from some manufacturers will not function perfectly in this device or are not completely compatible with it (you can obtain information on compatibility from the memory card manufacturer or supplier).

●For SINUMERIK 828D, only the memory card (2 GB) with order number 6FC5313-5AG00-0AA2 is permitted.

NOTICE

CompactFlash card system

●The CompactFlash card always comes formatted! You must not reformat it under any circumstances!

●To ensure that the system CompactFlash card functions properly, the card must not be repartitioned.

●In the event of a defect, the system software card must be replaced.

For information about restoring your system using an empty CompactFlash card, refer to the Service Manual.

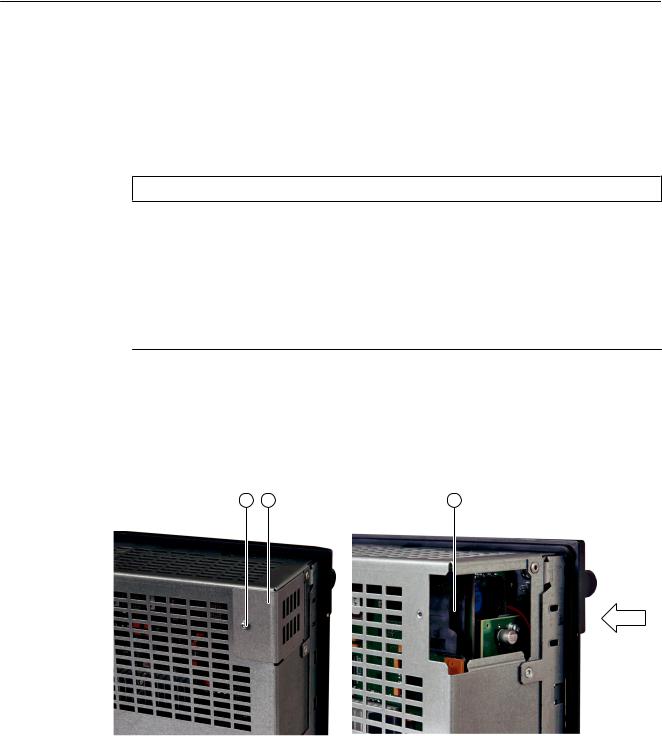

2.9.2Inserting the system CompactFlash Card

Slot and mounting position

M3 screw Metal cover Slot

The CompactFlash card has an edge on the opposite side to the pins. This edge must always be on the right when inserting the card.

|

30 |

PPU |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

System description

2.9 CompactFlash Cards

Figure 2-9 Mounting position

Replacing the system CompactFlash card

Electrostatic Device (ESD)

Before you touch a CompactFlash card, discharge yourself at the cabinet or at the ground terminal.

The CompactFlash cards may only be inserted or removed when the control unit is disconnected from the power supply.

Procedure:

1.Switch off the power supply.

2.Loosen the screw .

3.Swing the metal cover to the side and remove.

|

PPU |

31 |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

System description

2.9CompactFlash Cards

4.Pull out the CompactFlash card sideways.

5.Gently insert the new CompactFlash card into slot until it clicks into place.

6.Re-attachthemetalcover byfirstguidingitinbackward,thentiltingintotheendposition and finally screwing in the screw (max. tightening torque, 0.8 Nm).

NOTICE

Plugging in the CompactFlash card

Please ensure that the CompactFlash card is inserted with care. Otherwise, the card may be damaged.

7.Switch the power supply on again.

2.9.3CompactFlash card for user data

CompactFlash card for user data

You can write to the user CompactFlash card as follows:

●The user CompactFlash card is inserted in the front slot of the PPU and is written to via the operating software.

●The user CompactFlash card can be written to using a suitable memory card adapter directly via the PG/PC.

Note

A permanently inserted CompactFlash card can also be used as an extension of the CNC user memory, e.g. for oversized mold making programs, which exceed the storage capacity integrated in the CNC user memory.

|

32 |

PPU |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

System description

2.9 CompactFlash Cards

Inserting the CompactFlash card

To correctly insert the CompactFlash card in the slot, note the position the edge (arrow) in the figure below:

Figure 2-10 Direction to insert the user CompactFlash card

|

PPU |

33 |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

Application planning |

3 |

3.1Secondary electrical conditions

3.1.1Protective Separation as per EN 61800-5-1

Protective separation of the interfaces

Note

By using an extra-low voltage, all interfaces have protective separation according to Class DVC A (SELV/PELV).

3.1.2Grounding concept

Components

The SINUMERIK 828D system consists of a number of individual components which have been designed so that the system complies with the appropriate EMC and safety standards. The individual system components are:

●Panel Processing Unit PPU

●Machine Control Panel

●PLC I/O modules

Grounding measures

The PPU and MCP are attached with tensioners to a metal panel on the operator panel. Both have a protective conductor connection for grounding (grounding screw) at the rear of the device, which must be connected to the grounding bar of the control cabinet.

The SINAMICS S120 drive system is installed in the control cabinet. The electronics unit grounds of the modules are connected to each other via DRIVE-CLiQ. The modules are grounded either via the galvanized mounting plate or via the grounding lugs on the front of the modules.

The PLC I/O device modules are installed in the control cabinet and grounded via a grounding screw.

|

PPU |

35 |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

Application planning

3.1 Secondary electrical conditions

|

6ZLWF LQ |

F |

LQHW |

2SHU |

WRU S |

QHO |

||

|

36 |

33 |

‘ |

338 |

||||

|

36 |

|||||||

|

36 |

|||||||

|

0&3 |

|||||||

|

6,1$0,&6 |

|||||||

|

6 |

|||||||

|

36 LQ PRWRU F OH |

|||||||

|

36 |

0% |

||||||

|

34 |

* |

0b |

|||||

|

34 |

|||||||

|

*URXQGLQ |

U |

36 |

|||||

|

36 |

)HUURXV P F LQH |

||||||

|

FRQVWUXFWLRQ |

|||||||

|

([WHUQ O SURWHFWLYH FRQGXFWRU |

|

MB |

Shielded signal cable with reference ground |

MMotor

GEncoder

|

PA |

Equipotential bonding conductor |

|

PS |

Protective connection (via metal design or green-yellow protective conductors) |

|

Figure 3-1 |

Grounding concept |

The following rules apply for external cable cross sections:

●PA cross-section ≥ 10 mm2

●The conductor cross-section of the external protective conductor is calculated from the conductor cross-section of the line connection as follows:

|

Line connection S (mm2) |

External protective conductor min. (mm2) |

|

S ≤ 16 |

S |

|

16 ≤ S ≤ 35 |

16 |

|

S ≥ 35 |

S/2 |

|

36 |

PPU |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

Application planning

3.1 Secondary electrical conditions

3.1.3RI suppression measures

Shielded signal cables

In addition to the protective grounding of system components, special precautions must be taken to ensure safe, fault-free operation of the system. These measures include shielded signal cables, special equipotential bonding, isolation, and shielding measures.

●For safe and fault-free operation of the system, the specified cables must be used.

●For digital signal transmission, the shield must have a conductive connection at both sides of the housing.

Exception:

Standard shielded cables grounded on only one side can be used for devices from other manufacturers (printers, programming devices, etc.). However, these devices must not be connectedtothecontrollerduringnormaloperation.However,ifthesystemcannotoperate without them, then the cable shields must be connected at both ends. Furthermore, the non-Siemensdevicemustbeconnectedtothecontrollerviaanequipotentialbondingcable.

Cable definitions

The following cables are permissible:

●Signal cables:

–Data cables (Ethernet, PROFINET, DRIVE-CLiQ, sensor cables, etc.)

–Ribbon cables for digital inputs/outputs

–Emergency Stop cables

●Power cables:

–Low-voltage supply cables (230 VAC, 24 VDC, etc.)

–Supply cables to contactors (primary and secondary circuit)

Rules for routing cables

In order to maximize noise immunity for the complete system (controller, power section, machine) the following EMC measures must be observed:

●Signal cables and power cables must be routed at the greatest possible distance from one another.

●If necessary, signal and power cables may cross one another (if possible at an angle of 90°), but must never be laid close or parallel to one another.

●Signal cables may not be routed close to strong external magnetic fields (e.g. motors and transformers).

●Pulse-loaded HC/HV lines must always be laid completely separately from all other lines.

|

PPU |

37 |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

Application planning

3.1Secondary electrical conditions

●If signal lines cannot be routed a sufficient distance away from other cables, they must be installed in grounded cable ducts (metal).

●The clearance (interference injection area) between the following lines must be kept to a minimum:

–Signal line and electrical circuit signal line (twisted)

–Signal line and associated equipotential bonding conductor

–Equipotential bonding conductor and protective conductor (routed together)

References

For more information about interference suppression measures and connection of shielded cables and specified cables:

●EMC Installation Guideline Configuration Manual/Basic system requirements

●SINAMICS S120 Combi Manual

EMC limit values in South Korea

The EMC limit values to be complied with for South Korea correspond to the limit values of the EMC product standard for variable-speed electric drives EN 61800-3, Category C2, or limit valueclassA,Group1accordingtoEN55011.Byapplyingsuitablesupplementarymeasures, the limit values according to Category C2 or according to limit value class A, Group 1, are maintained. Further, additional measures may be required, for instance, using an additional radio interference suppression filter (EMC filter).

The measures for EMC-compliant design of the system are described in detail in this manual respectively in the Installation Guideline EMC.

Pleasenotethatthefinalstatementoncompliancewiththestandardisgivenbytherespective label attached to the individual unit.

|

38 |

PPU |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

Application planning

3.2 Climatic and mechanical environmental conditions

3.2Climatic and mechanical environmental conditions

3.2.1Ambient conditions

Observing the ambient conditions

The controller is tested for compliance with the ambient conditions specified below. Fault-free operation is only ensured if:

●These ambient conditions are maintained when storing, transporting and operating the equipment.

●Original components and spare parts are used. This applies in particular to the use of specified cables and connectors.

●The equipment is correctly installed and commissioned.

Standard requirements

The SINUMERIK 828D system components meet the following standard requirements:

|

Long-term storage |

EN 60721-3-1 |

|

Transport |

EN 60721-3-2 |

|

Stationary operation |

EN 60721-3-3 |

Assistance and support

Compliance with environmental requirements must be ensured during installation of the complete system. Please contact your sales representative for assistance and support.

3.2.2Transport and Storage Conditions

Components in original packaging

The following specifications apply to components in transport packaging:

|

Table 3-1 |

Climatic environmental conditions |

||

|

Transport |

Storage |

||

|

Standard / class |

EN 60721-3-2 / 2K4 |

EN 60721-3-1 / 1K4 |

|

|

Temperature range |

-20 |

… + 60 °C |

-25 … + 55 °C |

|

Temperature change |

-40 |

°C / +30 °C and +70 °C / +15 °C **) |

< 0.5 K / min ( 30 K / h) *) |

|

PPU |

39 |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

Application planning

3.2 Climatic and mechanical environmental conditions

|

Relative humidity |

5 … 95% |

10 … 100% |

|

|

Permissible change in |

max. 0.1% / min ( 6% / h) |

||

|

relative humidity |

Averaged over 5 min

Assuming a direct change in the specified air temperatures

3.2.3Operating Conditions

Note

Before commissioning components with display, remove the foil which is used to protect the components during transport.

Climatic environmental conditions

If the specified values cannot be maintained, then a heat exchanger or air conditioner must be provided.

|

Table 3-2 |

Climatic environmental conditions to EN 60721-3-3, Class 3K5 |

||||

|

Temperature range |

Front side: 0 … 45 °C |

Rear side: 0 … 55 °C |

|||

|

Temperature change |

< 0.5 K / min ( 30 K / h) averaged over 5 min |

||||

|

Humidity |

Relative: 5 … 90% at 25 °C |

Absolute: ≤ 25 g / m3 |

|||

|

Permissible change in relative |

max. 0.1% / min ( 6% / h) |

||||

|

humidity |

|||||

|

Moisture condensation and |

Not permissible |

||||

|

ice formation |

|||||

|

Dripping water, spray, splash |

Permissible |

||||

|

water, water jets |

|||||

|

Supply air |

Without aggressive gases, dusts and oils |

||||

|

Air pressure |

106 to 92 kPa or 0 to 1000 m above sea level |

||||

|

Derating |

At altitudes over 1,000 to 4,000 m above sea level, the upper |

||||

|

temperature limit must be reduced by 3.5 °C / 500 m. |

|||||

|

Active environmental |

Chemical: |

Mechanical: |

Biological: |

||

|

conditions |

Class 3C2 |

Class 3S2 |

Class 3B1 |

|

40 |

PPU |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

Application planning

3.3 Recycling and disposal

Function-impairing dust

When working in areas where gases, dust and oils may be hazardous to functionality, the controlsystemmustbeoperatedinanenclosurewithaheatexchangerorwithsuitablesupply air.

|

Table 3-3 |

Maximum permissible dust content in the air |

|

|

Suspended component |

0.2 mg/m3 |

|

|

Deposits |

1.5 mg/m2h |

Note

Dust deposits must be removed at regular intervals.

Radio interference

Applicable standards: EN 61800-3

Table 3-4 Limit values for radio interference suppression in industrial environments

|

Limit class according to EN 61800-3 |

|

|

Conducted radio interference |

C3 |

|

Radio interference |

C3 |

Note

The user must consider interference radiation for the complete system. Particular attention should be paid to cabling. Please contact your sales representative for assistance and support.

If compliance with limit value class C2 is required, please contact your local Siemens sales partner.

Note

Please see the relevant SINAMICS documentation for EMC notes on how to deal with line filters and reactors.

3.3Recycling and disposal

Products should be disposed of corresponding to the relevant national regulations.

The products described in this manual can be mostly recycled due to the fact that they contain very few damaging substances. To recycle and dispose of your old device in an environmentally friendly way, please contact an appropriate disposal company.

|

PPU |

41 |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

Installation notes

PPU modules may only be installed in housings, cabinets or in isolated electrical business establishments. Housings, cabinets, or isolated electrical business establishments may only be accessed by trained or authorized personnel.

Risk of electric shock

The entire system must be voltage-free when mounting or wiring the SINUMERIK 828D.

Components in the control cabinet

The SINAMICS components and the axis expansion modules are installed in a control cabinet.

References

Notes for mounting components of the SINAMICS S120 product family are contained in the following manuals:

●SINAMICS S120 Booksize Power Units Manual

●SINAMICS S120 Combi Manual

For further details on the control cabinet installation, refer to:

●«Control Cabinet Integration, SINAMICS S120 Booksize / SIMODRIVE» System Manual

4.1Mounting positions

Permitted mounting positions

The PPU is secured with special tensioning elements and tensioners in the operator panel housing. The tensioners are included in the scope of delivery.

Note

Installing the PPU

The maximum permissible tightening torque for the tensioning screws is 0.5 Nm and this value must not be exceeded.

|

PPU |

43 |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

Installing

4.1 Mounting positions

Installation of the horizontal PPU variant

Mounting frame

Figure 4-1 Clearance for ventilation and cables in the horizontal PPU

|

44 |

PPU |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

Installing

4.1 Mounting positions

Panel cutout of the horizontal PPU variant

Mounting frame Seal area

Pressure point for tensioners

Figure 4-2 Horizontal PPU panel cutout

|

PPU |

45 |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

Installing

4.1 Mounting positions

[ P 5]

$

Mounting frame Tensioner (10 parts) Seal

Shield contact Grounding screw M5 Interfaces

Figure 4-3 Horizontal PPU mounting

|

46 |

PPU |

|

Manual, 01/2014, 6FC5397-2DP40-3BA3 |

Installing

4.1 Mounting positions

Installation of the vertical PPU variant

Figure 4-4 Clearance for ventilation and cables in the vertical PPU

|

PPU |

47 |

|