-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

System Manual · 02/2008

SIRIUS 3RA6 Compact Starter

SIRIUS Infeed System for 3RA6

sirius

COMPACT STARTER

Related Manuals for Siemens Sirius Series

Summary of Contents for Siemens Sirius Series

-

Page 1

System Manual · 02/2008 SIRIUS 3RA6 Compact Starter SIRIUS Infeed System for 3RA6 sirius COMPACT STARTER… -

Page 3

Introduction Product-specific information System description SIRIUS industrial switchgear Configuration Load feeders, motor and soft starters Communication via AS-Interface SIRIUS 3RA6 Compact Starter Description of the hardware System Manual Functions Installation/Removal Connecting Commissioning Diagnostics Accessories Service Technical data Dimension drawings Circuit diagrams 02/2008 Appendix GWA 4NEB 560 0601-02 DS 02… -

Page 4

Trademarks All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this publication may be trademarks whose use by third parties for their own purposes could violate the rights of the owner. -

Page 5: Table Of Contents

Table of contents Introduction…………………………9 Product-specific information……………………11 Standards/Regulations/Approvals ………………..11 Use as prescribed ……………………12 System description ……………………..13 System overview ……………………..13 System configuration ……………………15 3.2.1 System configuration without optional AS-i mounting module………….16 3.2.2 System configuration with optional AS-i mounting module…………17 System components ……………………18 Configuration ……………………….

-

Page 6

Table of contents Removing the SIRIUS 3RA6 compact starter and AS-i mounting module ……… 64 8.2.1 Removing the compact starter from a DIN rail…………….64 8.2.2 Removing the compact starter from a level surface (screw fastening)……..65 8.2.3 Removing the compact starter from a SIRIUS infeed system for 3RA6 ……..66 8.2.4 Removing the AS-i mounting module ……………… -

Page 7

Table of contents 12.6 Terminal for Type E combination motor controller, UL 508 …………127 12.6.1 Installing the terminal for a Type E self-protected combination motor controller (UL 508)..127 12.6.2 Connecting the terminal for a Type E self-protected combination motor controller (UL 508) ……………………….128 12.7 Door-coupling rotary operating mechanism…………….129… -

Page 8

Table of contents Tables Table 1-1 Chapter overview …………………….. 9 Table 1-2 Symbols……………………….10 Table 3-1 Compact starter communication options………………13 Table 3-2 Accessories for the 3RA6 compact starter……………… 14 Table 3-3 Control circuit (configuration) …………………. 15 Table 4-1 Maximum rated current (3RA6 compact starter)…………….. 26 Table 4-2 Maximum rated current (infeed system for 3RA6) ………….. -

Page 9

Table of contents Table 12-5 Screw-type infeed (25/35 mm²) (L1, L2, L3) and PE infeed, 25/35 mm², with screw-type connection technology …………………..114 Table 12-6 Screw-type infeed (50/70 mm²) (L1, L2, L3) …………….114 Table 12-7 Spring-loaded infeed (L1, L2, L3) and PE infeed, 25/35 mm², with spring-loaded connection technology …………………..115 Table 12-8 Screw-type infeed (25/35 mm²) (T1, T2, T3), screw-type infeed (50/70 mm²) (T1, T2, T3),… -

Page 10

Table of contents Figure 12-7 Configuration involving 3-phase busbar………………118 Figure 12-8 Configuration involving 3-phase busbar to UL 508 (Type E) ………… 119 Figure 12-9 Installing the door-coupling rotary operating mechanism …………129 Figure 12-10 Door-coupling rotary operating mechanism; operating information ………. 131 Figure 12-11 Door-coupling rotary operating mechanism, securing ………….. -

Page 11: Introduction

Introduction Purpose of this manual This SIRIUS 3RA6 Compact Starter Manual describes the compact starter and its functions. It contains information about configuration, commissioning and servicing. As well as providing information about the compact starter itself, the manual also deals with compatible infeed systems.

-

Page 12: Table 1-2 Symbols

Introduction Chapter Contents Accessories Provides information about accessories (control kit, auxiliary switch block for compact starter, infeed system for 3RA6, 3-phase busbar, 8US busbar adapter, type E terminal, door-coupling rotary operating mechanism). This information includes a description of the hardware as well as the installation/removal and connection processes.

-

Page 13: Product-Specific Information

US market. Confirmation of approvals, test certificates and characteristic curves is available via the Internet: www.siemens.de/lowvoltage/technical-assistance Compact starter degree of protection The compact starter’s degree of protection is IP20. In the terminal area it features IP00 degree of protection.

-

Page 14: Use As Prescribed

IEC / EN 60204-1. Characteristic curves If required, you can request the characteristic curves for all setting ranges by sending an e- mail to our Technical Assistance team: technical-assistance@siemens.com. Alternatively, you can get them by visiting the following website: www.siemens.de/lowvoltage/technical-assistance…

-

Page 15: System Description

System description System overview General The SIRIUS 3RA6 compact starter is a universal motor feeder that meets the requirements of IEC / EN 60947-6-2 (weld-free). It combines the functions of a circuit breaker, a solid-state overload relay and a contactor within a single housing and can be used in any application involving the direct starting of standard induction motors with a rating of up to 32 A (approx.

-

Page 16: Table 3-2 Accessories For The 3Ra6 Compact Starter

System description 3.1 System overview Accessories As well as providing details of the compact starter and AS-i mounting module, this document also describes the following accessories: Table 3-2 Accessories for the 3RA6 compact starter Accessories Description Chapter Auxiliary switch block for Optional auxiliary switch block in External auxiliary switch block compact starter…

-

Page 17: System Configuration

System description 3.2 System configuration System configuration Main circuit The following supply options are available for the compact starter’s main circuit: ● Parallel wiring ● Infeed system for 3RA6 (For additional information, please refer to «SIRIUS infeed system for 3RA6 (Page 95)».) ●…

-

Page 18: System Configuration Without Optional As-I Mounting Module

System description 3.2 System configuration 3.2.1 System configuration without optional AS-i mounting module Configuration The compact starter is connected to the control system via parallel wiring. Control takes place via the following terminals: ● Direct starter: A1+, A2- ● Reversing starter: A1+, A2/B2-, B1+ View WARNING WARNING…

-

Page 19: System Configuration With Optional As-I Mounting Module

System description 3.2 System configuration 3.2.2 System configuration with optional AS-i mounting module The compact starter with 24 V control voltage can be controlled via an AS-Interface. The actuator sensor interface (AS-Interface) is a modular networking system for sensors and actuators at the lowest field level.

-

Page 20: System Components

System description 3.3 System components System components SIRIUS 3RA6 compact starter System component Order number Image 3RA61 compact starter 3RA61 direct starter 3RA62 compact starter 3RA62 reversing starter Main conductor terminal (2 terminals/package for incoming and outgoing terminals) — Screw-type connection technology 3RA6920-1A — Spring-loaded connection 3RA6920-2A…

-

Page 21

System description 3.3 System components System component Order number Image Auxiliary switch block for compact starter — Screw-type connection technology: 2 NO contacts 3RA6911-1A 2 NC contacts 3RA6912-1A 1 NO contact + 1 NC contact 3RA6913-1A — Spring-loaded connection technology: 2 NO contacts 3RA6911-2A 2 NC contacts… -

Page 22

System description 3.3 System components SIRIUS infeed system for 3RA6 System component Order number Image Left infeed, 50/70 mm² screw terminal with three slots, outgoing terminals with — Screw-type connection technology 3RA6813-8AB — Spring-loaded connection 3RA6813-8AC technology Incl. PE bar (for installing Type E starters in accordance with UL 508) Left infeed, 25/35 mm²… -

Page 23

System description 3.3 System components System component Order number Image Extension module with three slots, outgoing terminals with — Screw-type connection technology 3RA6823-0AB — Spring-loaded connection 3RA6823-0AC technology Incl. PE bar Left or right infeed, 25/35 mm², 3RA6830-5AC with spring-loaded connection technology PE infeed, 25/35 mm², with — Screw-type connection technology… -

Page 24

System description 3.3 System components System component Order number Image 45 mm adapter for infeed system for 3RA6890-0BA 3RA6 (for mounting size S0 circuit breakers (max. 12.5 A / 400 V; I < 53 kA) on the infeed system for 3RA6) Extension connector for 3RV19 3RA6890-1AA (connects SIRIUS infeed system for… -

Page 25

System description 3.3 System components System component Order number Image 3-phase infeed terminal 3RV1925-5EB for installing Type E starters, UL 508 with screw-type connection technology 8US busbar adapter System component Order number Image Busbar adapter 8US1211-1NS10 for 60 mm system Device holder for side mounting on 8US1250-1AA10 busbar adapter… -

Page 26

System description 3.3 System components Door-coupling rotary operating mechanism System component Order number Image Door-coupling rotary operating mechanism — 130 mm long 3RV1926-0B EMERGENCY OFF door-coupling rotary operating mechanism — 130 mm long 3RV1926-0C SIRIUS 3RA6 Compact Starter System Manual, 02/2008, GWA 4NEB 560 0601-02 DS 02… -

Page 27: Configuration

Configuration SIRIUS 3RA6 compact starter Assembly group installation The module can be installed horizontally (i.e. on a vertically installed DIN rail) or vertically (i.e. on a horizontally installed DIN rail). Safe isolation The following limit values must be observed to ensure safe isolation of the compact starters in accordance with IEC / EN 60947-1: ●…

-

Page 28: Table 4-1 Maximum Rated Current (3Ra6 Compact Starter)

Configuration 4.1 SIRIUS 3RA6 compact starter Required control power supply Depending on the version, the compact starter requires the following control power supply (AC/DC): ● 24 V ● 42 to 70 V ● 110 to 240 V Operating temperature The compact starter has been designed for use with ambient temperatures ranging from — 20 °C to + 40 °C.

-

Page 29: Figure 4-1 Distance Of Compact Starter From Neighboring Components (Dimensions In Mm)

Configuration 4.1 SIRIUS 3RA6 compact starter Short-circuit protection The compact starter has a rated ultimate short-circuit breaking capacity I of 53 kA at 400 V. If the short-circuit current at the installation point exceeds the compact starter’s specified rated ultimate short-circuit breaking capacity, then you will need to use a backup fuse.

-

Page 30: Supply Possibilities In Main Circuit

Configuration 4.2 Supply possibilities in main circuit Supply possibilities in main circuit The following supply options are available for the compact starter’s main circuit: ● Infeed via parallel wiring of individual compact starters ● Infeed via SIRIUS infeed system for 3RA6 ●…

-

Page 31

Configuration 4.2 Supply possibilities in main circuit WARNING Danger, high voltage! The maximum rated current for the extension connector is 63 A, regardless of the infeed block. If the rated current is exceeded, the extension connector will be damaged beyond repair. -

Page 32: Figure 4-2 Multi-Tier Configuration Of The Infeed System For 3Ra6

Configuration 4.2 Supply possibilities in main circuit Configuration The infeed system for 3RA6 can be installed horizontally or vertically. The main conductors can be connected to the screw-type infeeds of the infeed system from both the top and the bottom. Therefore, the infeed system for 3RA6 is particularly suitable for multi-tier configuration.

-

Page 33: Table 4-3 Short-Circuit Protection For Sirius Infeed System For 3Ra6

Configuration 4.2 Supply possibilities in main circuit Distance from neighboring components When installing the infeed system, the following distances from grounded or live parts and from neighboring components must be observed. ● Lateral distance from grounded parts: 10 mm ● Arcing space, top and bottom: 30 mm Figure 4-3 Distance of infeed system for 3RA6 from neighboring components (dimensions in mm) The installation guidelines for compact starters and circuit breakers/fuseless load feeders…

-

Page 34: Table 4-4 Short-Circuit Protection For Terminal Block (3Rv1917-5D)

Configuration 4.2 Supply possibilities in main circuit Conductor cross-sections Recommendation regarding upstream d,max short-circuit protection device (53 kA/400 VAC) Short-circuit protection for — Left infeed, 25/35 mm² screw terminal with three slots, outgoing terminals with screw-type connection technology, incl. PE bar (3RA6812-8AB) — Left infeed, 50/70 mm²…

-

Page 35: Figure 4-4 Combination With Other Sizes (Sirius Infeed System For 3Ra6)

Configuration 4.2 Supply possibilities in main circuit Options for combining the equipment with other products from the SIRIUS modular system Figure 4-4 Combination with other sizes (SIRIUS infeed system for 3RA6) The SIRIUS infeed system for 3RA6 combined with: The 3RV19 infeed system using the extension connector for 3RV19 (3RA6890-1AA). SIRIUS size S0 circuit breakers (max.

-

Page 36: 3-Phase Busbar

Configuration 4.2 Supply possibilities in main circuit 4.2.2 3-phase busbar Rated current/operating voltage ● Rated operating voltage: 690 V ● Rated current: 63 A Combination with other sizes The compact starters can be combined with size S0 circuit breakers using the 3-phase busbar (3RV1915-1.B) as well as with size S00 circuit breakers using the connection piece (3RV1915-5DB).

-

Page 37: 8Us Busbar Adapter

Configuration 4.2 Supply possibilities in main circuit 4.2.3 8US busbar adapter The compact starters are mounted on the 8US busbar adapter and connected on the line side. This ready-to-use unit plugs directly onto the busbar systems, thereby taking care of mechanical fastening and electrical connection at the same time.

-

Page 38: Infeed In Accordance With Ul 508 (Type E)

Configuration 4.2 Supply possibilities in main circuit 4.2.4 Infeed in accordance with UL 508 (Type E) According to UL 508 and CSA 22.2, a motor feeder is required to fulfill 4 sub-functions: Table 4-5 Sub-functions of motor feeders according to UL 508 and CSA 22.2 Sub-function Description Disconnect…

-

Page 39: Figure 4-7 Terminals For Infeed In Accordance With Ul 508 (Type E)

Configuration 4.2 Supply possibilities in main circuit The following supply possibilities are available for ensuring that the creepage and clearance requirements of UL 508 are met: Figure 4-7 Terminals for infeed in accordance with UL 508 (Type E) Type of infeed Infeed terminal (in accordance with UL 508, Type E) Order number Parallel wiring…

-

Page 40

Configuration 4.2 Supply possibilities in main circuit SIRIUS 3RA6 Compact Starter System Manual, 02/2008, GWA 4NEB 560 0601-02 DS 02… -

Page 41: Communication Via As-Interface

Communication via AS-Interface The actuator sensor interface (AS-Interface) is a modular networking system for sensors and actuators at the lowest field level. As far as the program in the control system is concerned, it makes no difference whether parallel wiring is used or whether the AS-Interface is used. As a result, it is possible to switch over to the AS-Interface even on existing systems, as you can continue to use any programs that are already installed.

-

Page 42

For additional information on addressing, please refer to «Addressing via AS-Interface (Page 82)». Certification by the AS-International association Siemens AS-Interface products are tested at an accredited test laboratory in accordance with the relevant testing regulations and certified by the AS-International association. SIRIUS 3RA6 Compact Starter… -

Page 43: Description Of The Hardware

Description of the hardware SIRIUS 3RA61 compact starter direct starter Features The 3RA61 compact starter direct starter is made up of the following components: ● Direct starter ● Two removable main conductor terminal blocks ● Two 6-pin removable auxiliary and control conductor terminal blocks (A1+/A2-, «overload»…

-

Page 44

Description of the hardware 6.1 SIRIUS 3RA61 compact starter direct starter 3RA61 compact starter direct starter Front view Function «Overload trip» mechanical display «Reset overload trip» button «Manual/auto reset» selector switch WARNING «Current setting I » setting wheel SIRIUS «Overload trip class» selector switch «Overload protection»… -

Page 45

Description of the hardware 6.1 SIRIUS 3RA61 compact starter direct starter Function Marking Description OFF: Compact starter is out of service Device status • • READY OFF and eye for padlock pulled out: Compact • • starter is out of service and secured against TRIPPED •… -

Page 46: Sirius 3Ra62 Compact Starter Reversing Starter

Description of the hardware 6.2 SIRIUS 3RA62 compact starter reversing starter SIRIUS 3RA62 compact starter reversing starter Features The 3RA62 compact starter reversing starter is made up of the following components: ● Reversing starter ● Two removable main conductor terminal blocks ●…

-

Page 47

Description of the hardware 6.2 SIRIUS 3RA62 compact starter reversing starter Configuration of 3RA62 compact starter reversing starter Front view Function «Overload trip» mechanical display «Reset overload trip» button «Manual/auto reset» selector switch WARNING «Current setting I » setting wheel «Overload trip class»… -

Page 48

Description of the hardware 6.2 SIRIUS 3RA62 compact starter reversing starter Function Marking Description OFF: Compact starter is out of service Device status • • READY OFF and eye for padlock pulled out: Compact • • starter is out of service and secured against TRIPPED •… -

Page 49: As-I Mounting Module For Compact Starter

Description of the hardware 6.3 AS-i mounting module for compact starter AS-i mounting module for compact starter Features The AS-i mounting module is mounted on the compact starter with 24 V control voltage, thereby enabling it to be controlled via an AS-Interface. The following components are required for this purpose: ●…

-

Page 50

Description of the hardware 6.3 AS-i mounting module for compact starter Configuration of AS-i mounting module with 2 local inputs for safe shutdown (3RA6970-3B) View Function 24 VDC PELV power supply unit connection AS-i data cable connection AS-i/Fault LED AUX Power LED Addressing unit connection Terminal for connecting a limit switch Display elements and operator controls on the AS-i mounting module… -

Page 51: Functions

Functions Normal switching duty Compact starters are mainly used for switching and protecting motors and also as main switches and disconnectors. The actuator can be used to switch the compact starter manually; together with the «ON I» LED it indicates the compact starter’s current status. The actuator has three positions: ●…

-

Page 52: Table 7-2 Actuator Display Elements Off (Reversing Starter)

Functions 7.1 Normal switching duty When the actuator is in the OFF position, the 3RA62 compact starter reversing starter can adopt the following statuses: Table 7-2 Actuator display elements OFF (reversing starter) Actuator LEDs Compact starter status ON I 1 ON I 2 A1/A2 B1/B2…

-

Page 53: Table 7-4 Actuator Display Elements Ready (Reversing Starter)

Functions 7.1 Normal switching duty When the actuator is in the READY position, the 3RA62 compact starter reversing starter can adopt the following statuses: Table 7-4 Actuator display elements READY (reversing starter) Actuator LEDs Compact starter status ON I 1 ON I 2 A1/A2 B1/B2…

-

Page 54

Functions 7.1 Normal switching duty Note Turning the actuator manually to the TRIPPED position The actuator can also be moved to the TRIPPED position manually. In this case, it is not possible to say whether a short circuit has occurred or whether the actuator has been moved to the TRIPPED position manually simply by looking at the display elements. -

Page 55: Overload Protection Function

Functions 7.2 Overload protection function Overload protection function Function The compact starter protects three-phase motors against overload. Consequently, the compact starter can shut down without the breaker latching mechanism having to open. The compact starter is also equipped with phase failure protection in order to minimize heating of the load in the event of a phase failure during single-phase operation.

-

Page 56: Figure 7-1 Manual/Auto Reset Following An Overload Trip

Functions 7.2 Overload protection function Manual/auto reset Figure 7-1 Manual/auto reset following an overload trip Overload trip Auto reset Manual reset (t < 3 minutes following overload trip) Manual reset (t < 3 minutes following overload trip) Overload trip Manual reset (t > 3 minutes following overload trip) If the «Manual/auto reset»…

-

Page 57

Functions 7.2 Overload protection function NOTICE Risk of a new overload trip! If a manual reset is performed within 3 minutes of the overload trip and the compact starter switches on, there is a risk of a new overload trip occurring immediately due to the fact that the motor/motor model may not yet have had a chance to cool down sufficiently (curve (4)). -

Page 58: Short-Circuit Protection Function

Functions 7.3 Short-circuit protection function Short-circuit protection function Function The SIRIUS 3RA6 compact starter’s short-circuit releases are designed to isolate the faulty load feeder from the supply system in the event of a short circuit in order to prevent any further damage.

-

Page 59: Shutdown On Malfunction

Functions 7.4 Shutdown on malfunction Shutdown on malfunction Type of malfunction There is a patented mechanism for detecting malfunctions, which opens the main contacts. The following malfunctions can be detected: ● End of service life – Worn switching contacts. (For additional information on electrical endurance, please refer to «Technical data (Page 145)».) –…

-

Page 60: Disabling The Actuator

Functions 7.5 Disabling the actuator Disabling the actuator Disabling the actuator You can disable the actuator to protect it against unauthorized closing by locking it with a padlock (shackle diameter 3.5 — 4.5 mm). Before you can do this, the actuator must be set to OFF position and the actuator eye must be pulled out.

-

Page 61: Installation/Removal

Installation/Removal Installing the SIRIUS 3RA6 compact starter and AS-i mounting module The sections below explain how to install the SIRIUS 3RA6 compact starter on: ● A DIN rail ● A level surface (screw fastening) ● The infeed system for 3RA6 The process of installing the AS-i mounting module on the compact starter (24 V) is also described.

-

Page 62: Installing The Compact Starter On A Level Surface (Screw Fastening)

Installation/Removal 8.1 Installing the SIRIUS 3RA6 compact starter and AS-i mounting module 8.1.2 Installing the compact starter on a level surface (screw fastening) Requirements ● Look up the order numbers pertaining to the adapters for screw fastening by referring to the list in «System components (Page 18)».

-

Page 63: Figure 8-1 Installing A 3Ra62 Compact Starter On A Level Surface (Screw Fastening)

Installation/Removal 8.1 Installing the SIRIUS 3RA6 compact starter and AS-i mounting module Virtually the same process is used for installing the reversing starter on a level surface as for the direct starter. However, in this case 2 additional adapters just need to be snapped onto the reversing starter and a single lug is used for surface mounting.

-

Page 64: Installing The Compact Starter On A Sirius Infeed System For 3Ra6

Installation/Removal 8.1 Installing the SIRIUS 3RA6 compact starter and AS-i mounting module 8.1.3 Installing the compact starter on a SIRIUS infeed system for 3RA6 Requirements ● The SIRIUS infeed system for 3RA6 must be correctly installed. For additional information on installing the infeed system, please refer to «SIRIUS infeed system for 3RA6 (Page 95)».

-

Page 65: Installing The As-I Mounting Module

Installation/Removal 8.1 Installing the SIRIUS 3RA6 compact starter and AS-i mounting module 8.1.4 Installing the AS-i mounting module Requirements NOTICE There is a risk of damage to the AS-i mounting module. If you install the AS-i mounting module on a compact starter that has a control voltage of more than 24 V, the AS-i mounting module will be supplied with too much power.

-

Page 66: Removing The Sirius 3Ra6 Compact Starter And As-I Mounting Module

Installation/Removal 8.2 Removing the SIRIUS 3RA6 compact starter and AS-i mounting module Removing the SIRIUS 3RA6 compact starter and AS-i mounting module The sections below explain how to remove the SIRIUS 3RA6 compact starter from: ● A DIN rail ● A level surface (screw fastening) ●…

-

Page 67: Removing The Compact Starter From A Level Surface (Screw Fastening)

Installation/Removal 8.2 Removing the SIRIUS 3RA6 compact starter and AS-i mounting module 8.2.2 Removing the compact starter from a level surface (screw fastening) Requirements ● The compact starter must be switched off (actuator set to OFF position). ● The control and auxiliary conductor terminals must be disconnected. DANGER Danger, high voltage! If removing the compact starter when the system is live, you must remember to set the…

-

Page 68: Removing The Compact Starter From A Sirius Infeed System For 3Ra6

Installation/Removal 8.2 Removing the SIRIUS 3RA6 compact starter and AS-i mounting module 8.2.3 Removing the compact starter from a SIRIUS infeed system for 3RA6 Requirements ● Screwdriver with max. diameter of 7.5 mm and minimum shaft length of 100 mm for releasing the compact starter ●…

-

Page 69

Installation/Removal 8.2 Removing the SIRIUS 3RA6 compact starter and AS-i mounting module When removing a reversing starter, you will need to insert two screwdrivers into the neighboring openings at the same time. Step Instructions Image Insert 2 screwdrivers into the opening above the reversing starter. -

Page 70: Removing The As-I Mounting Module

Installation/Removal 8.2 Removing the SIRIUS 3RA6 compact starter and AS-i mounting module 8.2.4 Removing the AS-i mounting module Requirements NOTICE There is a risk of damage to the AS-i mounting module. When removing the AS-i mounting module, please observe the ESD regulations, as electrostatic charging can damage it.

-

Page 71: Connecting

Connecting General connection information The SIRIUS 3RA6 compact starter is universally available with screw-type and spring-loaded connection technology. Stripping lengths A stripping length of 10 mm applies in respect of the main, auxiliary and control conductor connections. The terminals are marked to make it easier to determine the stripping length. The correct stripping length can be achieved by lining the conductor up with this marking.

-

Page 72: Figure 9-2 Test Probe Openings On The 3Ra6 Compact Starter

Connecting 9.1 General connection information Openings for test probes On the compact starter with screw-type connection technology, the test probes are attached to the terminal screws. On the compact starter with spring-loaded connection technology, all terminals are equipped with special test probe openings. Figure 9-2 Test probe openings on the 3RA6 compact starter Openings for test probes on…

-

Page 73: Table 9-1 Conductor Cross-Sections Of Main Conductor Terminals

Connecting 9.1 General connection information Conductor cross-sections of main conductor terminals Table 9-1 Conductor cross-sections of main conductor terminals Compact starter … 12 A 8 … 32 A … 12 A 8 … 32 A 8WA2 803 ∅ 6 mm/PZ 2 (3.5 x 0.5) mm 2 ……

-

Page 74: Table 9-2 Conductor Cross-Sections Of Auxiliary Conductor Terminals

Connecting 9.1 General connection information Conductor cross-sections of auxiliary and control conductor terminals Table 9-2 Conductor cross-sections of auxiliary conductor terminals (0.5 x 3.0) mm ∅ 6 mm/PZ 2 DIN ISO 2380-1A 0.8 … 1.2 Nm (7 to 10.3 lb·in) 1 x (0.5 ……

-

Page 75: Connecting Terminal Blocks

Connecting 9.2 Connecting terminal blocks Connecting terminal blocks DANGER Danger, high voltage! Electrical voltage can result in electric shocks or burns. Before starting work, disconnect the system and devices from the power supply. Requirements for screw terminals ● The connection cables must have been bared correctly. ●…

-

Page 76

Connecting 9.2 Connecting terminal blocks Requirements for spring-loaded terminals ● Main conductor terminals: Flat-head screwdriver with (3.5 x 0.5 mm) blade (8WA2 803) ● Auxiliary conductor terminals: Flat-head screwdriver with (3.0 x 0.5 mm) blade (DIN ISO 2380-1A) Procedure for spring-loaded terminal block Step Instructions Image… -

Page 77: Connecting The Compact Starter Without Optional As-I Mounting Module

Connecting 9.3 Connecting the compact starter without optional AS-i mounting module Connecting the compact starter without optional AS-i mounting module Connection method All auxiliary and control conductor connections on the compact starter converge at the same central point: the outgoing terminal. The terminals are universally available with screw-type or spring-loaded connection technology.

-

Page 78: Table 9-4 Pin Assignments For 3Ra62 Compact Starter Reversing Starter

Connecting 9.3 Connecting the compact starter without optional AS-i mounting module Table 9-4 Pin assignments for 3RA62 compact starter reversing starter Terminal Description Image 1L1, 3L2, 5L3 Main conductor terminals (line side) A1+, A2/B2-, B1+ Control voltage connection (AC/DC 24 V, 42 — 70 V or 110 — 240 V) A: Direction of rotation 1 B: Direction of rotation 2 WARNING…

-

Page 79: Connecting The Compact Starter (24 V) With Optional As-I Mounting Module

Connecting 9.4 Connecting the compact starter (24 V) with optional AS-i mounting module Connecting the compact starter (24 V) with optional AS-i mounting module To enable communication via an AS-Interface, the AS-i mounting module must first be installed on the compact starter (24 V). Then the AS-i mounting module can be connected to the AS-Interface using the AS-i cables.

-

Page 80: Connecting Limit Switches

Connecting 9.4 Connecting the compact starter (24 V) with optional AS-i mounting module 9.4.2 Connecting limit switches The AS-i mounting module for compact starters with two local inputs for safe shutdown (3RA6970-3B) can have equipment such as a limit switch connected to it. Consequently, safe shutdown up to category 2 in accordance with EN ISO 13849-1 is supported.

-

Page 81: Disconnecting Terminal Blocks

Connecting 9.5 Disconnecting terminal blocks Disconnecting terminal blocks Requirements ● The compact starter must be switched off (actuator set to OFF position). DANGER Danger, high voltage! Electrical voltage can result in electric shocks or burns. Before starting work, disconnect the system and devices from the power supply. Procedure for screw terminals Step Instructions…

-

Page 82

Connecting 9.5 Disconnecting terminal blocks Procedure for spring-loaded terminals Step Instructions Image Insert the flat-head screwdriver into the square opening of the spring-loaded terminal as far as it will go. Please observe a 10° horizontal angular deviation of the screwdriver to the oval opening. -

Page 83: Commissioning

Commissioning 10.1 Settings on the compact starter All settings are made on the device itself. CLASS 10/20 The CLASS (overload trip class) indicates the tripping time t of the compact starter (from cold) at 7.2 times the current setting I .

-

Page 84: As-Interface

Commissioning 10.2 AS-Interface 10.2 AS-Interface 10.2.1 Addressing via AS-Interface Before it can participate in data exchange with the master, each module must be assigned an individual address on the AS-Interface. Each address can only be used once on each AS-i network. On the AS-i mounting module, an extended master can be used to access the extended address mode (A/B technology).

-

Page 85

Commissioning 10.2 AS-Interface Procedure The AS-i mounting module is addressed via an addressing socket, e.g. using the AS-Interface addressing unit. The connecting cable is used to connect this unit to the addressing socket. Step Instructions Image If the AS-i mounting module on the compact starter is to be addressed via the addressing socket, remember to switch off the AS-i voltage. -

Page 86: Process Data And Process Images

Commissioning 10.2 AS-Interface 10.2.2 Process data and process images Process image The process image is used for buffering input and output data. When the control system starts cyclic program execution, the signal states of the compact starter are transferred to the process input image of the higher-level control system.

-

Page 87: Diagnostics

Diagnostics 11.1 Compact starter diagnostics Direct starter display concept Table 11-1 Display concept of the 3RA61 compact starter direct starter Compact starter status Actuator LED display Mechanical display ON I A1/A2 RLT 0% TRIP Switched off (delivery condition) Control voltage present with actuator set to OFF Ready READY…

-

Page 88: Table 11-2 Display Concept Of The 3Ra62 Compact Starter Reversing Starter

Diagnostics 11.1 Compact starter diagnostics Reversing starter display concept Table 11-2 Display concept of the 3RA62 compact starter reversing starter Compact starter status Actuator LED display Mechanical display ON I 1 ON I 2 A1/A2 RLT 0% TRIP B1/B2 Switched off (delivery condition) Attempt to switch on (direction of rotation 1 or 2)

-

Page 89: As-I Mounting Module Diagnostics

Diagnostics 11.2 AS-i mounting module diagnostics 11.2 AS-i mounting module diagnostics The status of the AS-i mounting module is indicated by means of two LEDs, which will either light up continuously or flash. Making straightforward diagnostics available directly on the AS-i mounting module in this way enables the user to troubleshoot quickly and efficiently.

-

Page 90

Diagnostics 11.2 AS-i mounting module diagnostics SIRIUS 3RA6 Compact Starter System Manual, 02/2008, GWA 4NEB 560 0601-02 DS 02… -

Page 91: Accessories

Accessories 12.1 Control kit 12.1.1 Description of the hardware Features The control kit is a tool for checking the wiring of the main and auxiliary circuits as well as the motor direction. The control kit is installed on the compact starter and bypasses the electromechanical operating mechanism so that electrical control can be simulated for the compact starter.

-

Page 92

Accessories 12.1 Control kit Requirements ● The compact starter must be switched off (actuator set to OFF position). Procedure Step Instructions Image Turn the actuator to the OFF position. Plug the control kit into the connection point (2a), inserting it from the bottom at an angle. -

Page 93: External Auxiliary Switch Block

Accessories 12.2 External auxiliary switch block 12.2 External auxiliary switch block 12.2.1 Description of the hardware An auxiliary switch block can be mounted on the 3RA61 compact starter direct starter. Two auxiliary switch blocks can be mounted on the 3RA62 compact starter reversing starter. The contacts of the auxiliary switch open and close along with the main contacts.

-

Page 94

Accessories 12.2 External auxiliary switch block Installing the auxiliary switch block Step Instructions Image Insert the auxiliary switch block into the location holes on the compact starter. Push the auxiliary switch block up until it engages. Removing the auxiliary switch block Step Instructions Image… -

Page 95: Connecting The Auxiliary Switch Block For Compact Starter

Accessories 12.2 External auxiliary switch block 12.2.3 Connecting the auxiliary switch block for compact starter The terminals on the auxiliary switch block are available with screw-type or spring-loaded connection technology. For additional information on the connection systems, please refer to «Connecting terminal blocks (Page 73)».

-

Page 96: Table 12-2 Conductor Cross-Section Of The Terminals On The Auxiliary Switch Block For Compact Starter

Accessories 12.2 External auxiliary switch block Conductor cross-sections Table 12-2 Conductor cross-section of the terminals on the auxiliary switch block for compact starter 3RA691.-1A 3RA691.-2A 8WA2 807 ∅ 6 mm/PZ 2 (2.5 x 0.4) mm 0.8 … 1.2 Nm (7 to 10.3 lb·in) 2 x (0.5 …

-

Page 97: Sirius Infeed System For 3Ra6

Accessories 12.3 SIRIUS infeed system for 3RA6 12.3 SIRIUS infeed system for 3RA6 12.3.1 Description of the hardware Features The SIRIUS infeed system for 3RA6 is a pre-wired infeed system for the compact starter. The infeed system for 3RA6 is characterized by the permanent wiring of the main circuit, the PE infeed and PE tap.

-

Page 98: Figure 12-1 Infeed System For 3Ra6

Accessories 12.3 SIRIUS infeed system for 3RA6 Figure 12-1 Infeed system for 3RA6 Screw-type infeed (25/35 mm Screw-type infeed (50/70 mm Spring-loaded infeed Extension block SIRIUS 3RA6 Compact Starter System Manual, 02/2008, GWA 4NEB 560 0601-02 DS 02…

-

Page 99: Coding The Sirius Infeed System For 3Ra6

Accessories 12.3 SIRIUS infeed system for 3RA6 Combination with other sizes The infeed system for 3RA6 can be connected to the SIRIUS 3RV19 infeed system using the extension connector for 3RV19 (3RA6890-1AA). SIRIUS size S0 circuit breakers (max. 12.5 A / 400 V; I <…

-

Page 100: Figure 12-3 Coding The Sirius Infeed System For 3Ra6

Accessories 12.3 SIRIUS infeed system for 3RA6 Each slot is individually coded for compact starters with a particular current setting range. Figure 12-3 Coding the SIRIUS infeed system for 3RA6 Slot 1 coding Slot 4 coding Slot 2 coding Slot 5 coding Slot 3 coding The following options are available for coding the infeed system slots: Coding…

-

Page 101: Installing The Sirius Infeed System For 3Ra6 On A Din Rail

Accessories 12.3 SIRIUS infeed system for 3RA6 12.3.3 Installing the SIRIUS infeed system for 3RA6 on a DIN rail Requirements ● A 35-mm mounting rail in accordance with IEC / EN 60715 must be properly secured at the installation location. Mounting the screw-type infeed on the DIN rail The procedure for installing the 25/35 mm²…

-

Page 102

Accessories 12.3 SIRIUS infeed system for 3RA6 WARNING Danger, high voltage! The maximum rated current for the extension connector is 63 A, regardless of the infeed block. If the maximum rated current is exceeded, the extension connector will be damaged beyond repair. -

Page 103

Accessories 12.3 SIRIUS infeed system for 3RA6 Expanding the SIRIUS infeed system for 3RA6 by means of additional extension modules Screw-type infeeds and extension blocks can be expanded by adding additional 3-slot and 2-slot extension modules. The screw-type infeeds can only be expanded by adding modules to the right. With spring-loaded connection technology, the extension module can be added to the right or left, depending on which side the spring-loaded infeed has been installed. -

Page 104

Accessories 12.3 SIRIUS infeed system for 3RA6 Step Instructions Image Use the 3 link wedges to establish a mechanical connection between the 2 modules. Use an extension connector to establish an electrical connection between the 2 modules. Attach the end cover to the additional extension module. -

Page 105: Installing The Sirius Infeed System For 3Ra6 On A Level Surface (Screw Fastening)

Accessories 12.3 SIRIUS infeed system for 3RA6 12.3.4 Installing the SIRIUS infeed system for 3RA6 on a level surface (screw fastening) Requirements ● Drill holes with thread or plug on the level surface. For details of the distances between the drilled holes, please refer to the relevant dimension drawing in «Dimension drawings (Page 161)».

-

Page 106: Installing The Accessories For A Sirius Infeed System For 3Ra6

Accessories 12.3 SIRIUS infeed system for 3RA6 12.3.5 Installing the accessories for a SIRIUS infeed system for 3RA6 Installing PE accessories The PE infeeds and taps are available with screw-type or spring-loaded connection technology. The PE infeed can be mounted to the right or left of the screw-type infeeds and extension modules.

-

Page 107

Accessories 12.3 SIRIUS infeed system for 3RA6 Step Instructions Image Push the PE infeed against the right-hand/left-hand side of the screw-type infeed or extension module and then push it upwards. Press the link wedge down. Use the PE extension connector to connect the PE infeed and screw-type infeed/extension module. -

Page 108

Accessories 12.3 SIRIUS infeed system for 3RA6 Installing the terminal block The terminal block is available with spring-loaded connection technology. It can be installed on the right or left-hand side of the extension module. Step Instructions Image Remove the end cover from the extension module. -

Page 109

Accessories 12.3 SIRIUS infeed system for 3RA6 Installing the 45 mm adapter for infeed system for 3RA6 Step Instructions Image Snap the back of the circuit breaker onto the upper edge of the DIN rail, connecting it to the 45 mm adapter for 3RA6 infeed systems. -

Page 110: Removing The Accessories For A Sirius Infeed System For 3Ra6

Accessories 12.3 SIRIUS infeed system for 3RA6 12.3.6 Removing the accessories for a SIRIUS infeed system for 3RA6 Requirements DANGER Danger, high voltage! Electrical voltage can result in electric shocks or burns. Before starting work, disconnect the system and devices from the power supply. ●…

-

Page 111: Removing The Sirius Infeed System For 3Ra6 From A Din Rail

Accessories 12.3 SIRIUS infeed system for 3RA6 12.3.7 Removing the SIRIUS infeed system for 3RA6 from a DIN rail The infeed system for 3RA6 is either installed on a DIN rail or on a level surface (screw fastening). The removal process is basically the same for both mounting types. The only difference between the two is how the extension modules are fastened.

-

Page 112

Accessories 12.3 SIRIUS infeed system for 3RA6 Removing a spring-loaded infeed with extension module from a DIN rail The spring-loaded infeed is mounted on the right or left of a 3-slot or 2-slot extension module. WARNING Danger, high voltage! Removing the extension connector from the infeed system for 3RA6 while the system is live can damage both the extension connector and infeed system and can also result in an electric shock. -

Page 113

Accessories 12.3 SIRIUS infeed system for 3RA6 Removing additional extension modules Screw-type and spring-loaded infeeds can be expanded by means of additional 3-slot and 2-slot extension modules. Screw-type infeeds can only be expanded by adding modules to the right. Spring-loaded infeeds can be expanded by adding modules to the right or left, depending on which side the spring-loaded infeed has been installed. -

Page 114: Connecting The Sirius Infeed System For 3Ra6

Accessories 12.3 SIRIUS infeed system for 3RA6 12.3.8 Connecting the SIRIUS infeed system for 3RA6 The SIRIUS infeed system for 3RA6 is available with screw-type and spring-loaded connection technology. The main conductors (L1, L2, L3) can be connected to the screw-type infeed (25/35 mm and screw-type infeed (50/70 mm ) from both the top and the bottom.

-

Page 115: Figure 12-6 Test Probe Openings On The Infeed System

Accessories 12.3 SIRIUS infeed system for 3RA6 Openings for test probes On the infeed system with screw-type connection technology, the test probes are attached to the terminal screws. On the infeed system with spring-loaded connection technology, all terminals are equipped with special test probe openings.

-

Page 116: Connection Technology

Accessories 12.3 SIRIUS infeed system for 3RA6 Conductor cross-sections Table 12-5 Screw-type infeed (25/35 mm²) (L1, L2, L3) and PE infeed, 25/35 mm², with screw-type connection technology 3RA6812-8AB (L1, L2, L3) 3RA6812-8AC (L1, L2, L3) 3RA6860-6AB 3 … 4.5 Nm (27 ……

-

Page 117

Accessories 12.3 SIRIUS infeed system for 3RA6 Table 12-7 Spring-loaded infeed (L1, L2, L3) and PE infeed, 25/35 mm², with spring-loaded connection technology 3RA6830-5AC 3RA6860-5AC 8WA2 806 (5.5 x 0.8 mm) 4 … 35 mm 6 … 25 mm 4 … 25 mm 10 to 3 Table 12-8 Screw-type infeed (25/35 mm²) (T1, T2, T3), screw-type infeed (50/70 mm²) (T1, T2, T3), 2-slot/3-slot… -

Page 118: Table 12-10 Terminal Block

Accessories 12.3 SIRIUS infeed system for 3RA6 Table 12-9 PE tap, 6/10 mm , with spring-loaded connection technology 3RA6870-3AC 8WA2 803 (3.5 x 0.5 mm) 1.5 … 10 mm 1.5 … 6 mm 1.5 … 6 mm 16 to 10 1 x 8 Table 12-10 Terminal block 3RV1917-5D…

-

Page 119: 3-Phase Busbar

Accessories 12.4 3-phase busbar 12.4 3-phase busbar 12.4.1 Description of the hardware 3-phase busbars enable several compact starters to be fed using a single infeed terminal. The 3-phase busbars are finger-safe in terms of touch protection. They have been dimensioned to withstand the level of short-circuit stress that can occur on the output side of the connected compact starters.

-

Page 120

Accessories 12.4 3-phase busbar Accessories ● Connection piece (3RV1915-5DB): A connection piece is used to connect two 3-phase busbars with 45 mm modular spacing if you are using compact starters together with size S00 circuit breakers. ● Cover cap for terminal lugs (3RV1915-6AB): Cover caps provide touch protection for reserved slots as well as any that are not in use (e.g. -

Page 121

Accessories 12.4 3-phase busbar Configuration involving 3-phase busbar and 3-phase infeed terminal for installing Type E starters, UL 508 Figure 12-8 Configuration involving 3-phase busbar to UL 508 (Type E) SIRIUS 3RA6 Compact Starter System Manual, 02/2008, GWA 4NEB 560 0601-02 DS 02… -

Page 122: Connecting The 3-Phase Busbar

Accessories 12.4 3-phase busbar 12.4.2 Connecting the 3-phase busbar The 3-phase infeed terminals are available with screw-type connection technology. 3-phase infeed terminals There are 3 supply possibilities available for the 3-phase busbar: ● 3-phase infeed terminal, connection from the top, with screw-type connection technology (3RV1925-5AB) ●…

-

Page 123: 8Us Busbar Adapter

Accessories 12.5 8US busbar adapter 12.5 8US busbar adapter 12.5.1 Description of the hardware To save space when installing compact starters and to save time as far as the infeed is concerned, busbar adapters are used to mount the compact starters directly onto busbar systems.

-

Page 124: Installing The 8Us Busbar Adapter Plus Sirius 3Ra6 Compact Starter

Accessories 12.5 8US busbar adapter 12.5.2 Installing the 8US busbar adapter plus SIRIUS 3RA6 compact starter Requirements ● The compact starter must be switched off (actuator set to OFF position). ● The busbars must be disconnected from the power supply when the 8US busbar adapter is mounted on the busbars.

-

Page 125

Accessories 12.5 8US busbar adapter Procedure for 3RA61 compact starter direct starter Note The 8US busbar adapter plus compact starters must be arranged side by side on the busbar system without any space in between in order to meet the specified vibratory load and shock load requirements. -

Page 126

Accessories 12.5 8US busbar adapter Step Instructions Image Push the mounting lug into the adapter from the bottom. Snap the compact starter onto the DIN rail, connecting it to the busbar adapter. Insert each of the screws through the relevant holes in the mounting lug and screw the compact starter onto the busbar adapter. -

Page 127

Accessories 12.5 8US busbar adapter Step Instructions Image Click the adapter for screw fastening the reversing starter into position behind the lower main conductor terminal. Snap the reversing starter onto the DIN rail, connecting it to the busbar adapter and device holder. Push the mounting lug into the adapter from the bottom. -

Page 128: Removing The 8Us Busbar Adapter Plus Sirius 3Ra6 Compact Starter

Accessories 12.5 8US busbar adapter 12.5.3 Removing the 8US busbar adapter plus SIRIUS 3RA6 compact starter Requirements ● The compact starter must be switched off (actuator set to OFF position). ● The busbars must be disconnected from the power supply when the 8US busbar adapter is removed from the busbars.

-

Page 129: Terminal For Type E Combination Motor Controller, Ul 508

Accessories 12.6 Terminal for Type E combination motor controller, UL 508 12.6 Terminal for Type E combination motor controller, UL 508 12.6.1 Installing the terminal for a Type E self-protected combination motor controller (UL 508) According to UL 508 (Type E), line-side clearances of 1 and 2 inches are required for Type E combination motor controllers.

-

Page 130: Connecting The Terminal For A Type E Self-Protected Combination Motor Controller (Ul 508)

Accessories 12.6 Terminal for Type E combination motor controller, UL 508 12.6.2 Connecting the terminal for a Type E self-protected combination motor controller (UL 508) Conductor cross-sections Table 12-13 Conductor cross-sections of the terminal for a self-protected combination motor controller (Type E) to UL 508 3RV1928-1H 2.5 ……

-

Page 131: Door-Coupling Rotary Operating Mechanism

Accessories 12.7 Door-coupling rotary operating mechanism 12.7 Door-coupling rotary operating mechanism 12.7.1 Description of the hardware Door-coupling rotary operating mechanisms consist of a lockable rotary operating mechanism with a removable door coupling, an extension shaft and a connection piece that joins onto the switch mechanism.

-

Page 132: Commissioning The Door-Coupling Rotary Operating Mechanism

Accessories 12.7 Door-coupling rotary operating mechanism 12.7.3 Commissioning the door-coupling rotary operating mechanism Opening the door The following table explains how to open the control cabinet door with the door-coupling rotary operating mechanism. Instructions Image To open the control cabinet door, set the compact starter to the OFF position.

-

Page 133: Figure 12-10 Door-Coupling Rotary Operating Mechanism; Operating Information

Accessories 12.7 Door-coupling rotary operating mechanism Figure 12-10 Door-coupling rotary operating mechanism; operating information The extension shaft then needs to be attached to the compact starter and door-coupling rotary operating mechanism as described below: Step Instructions Image Switch off the compact starter ( OFF) and turn the rotary switch of the door-coupling rotary operating mechanism to…

-

Page 134: Figure 12-11 Door-Coupling Rotary Operating Mechanism, Securing

Accessories 12.7 Door-coupling rotary operating mechanism Locking In the OFF position, the rotary operating mechanism can be secured using up to 3 locks, e.g. while maintenance work is carried out on the system. Figure 12-11 Door-coupling rotary operating mechanism, securing SIRIUS 3RA6 Compact Starter System Manual, 02/2008, GWA 4NEB 560 0601-02 DS 02…

-

Page 135: Service

Service The SIRIUS 3RA6 compact starter and SIRIUS infeed system for 3RA6 have been designed to be maintenance-free. 13.1 Installing/Removing main conductor terminal blocks Requirements DANGER Danger, high voltage! Electrical voltage can result in electric shocks or burns. Before starting work, disconnect the systems and devices from the power supply. ●…

-

Page 136

Service 13.1 Installing/Removing main conductor terminal blocks Installing main conductor terminal blocks Step Instructions Image Insert the removable main conductor terminal block into the device’s mechanically coded guiderail from the back. Then push it forwards until you hear it engage. SIRIUS 3RA6 Compact Starter System Manual, 02/2008, GWA 4NEB 560 0601-02 DS 02… -

Page 137: Installing/Removing Auxiliary And Control Conductor Terminal Blocks

Service 13.2 Installing/Removing auxiliary and control conductor terminal blocks 13.2 Installing/Removing auxiliary and control conductor terminal blocks Installing auxiliary and control conductor terminal blocks on the compact starter The auxiliary and control conductor terminals are mechanically coded to prevent mix-ups. The terminals are marked as follows: Figure 13-1 Coding of auxiliary and control conductor terminals…

-

Page 138

Service 13.2 Installing/Removing auxiliary and control conductor terminal blocks Installing auxiliary and control conductor terminal blocks on the compact starter Step Instructions Image Insert the removable terminal block into the device’s mechanically coded guiderail from the bottom. Push the terminal block up and then back until you hear it engage. -

Page 139: Malfunction (E.g. End Of Service Life Reached)

Service 13.3 Malfunction (e.g. end of service life reached) 13.3 Malfunction (e.g. end of service life reached) The SIRIUS 3RA6 compact starter features a patented mechanism for detecting malfunctions. If a malfunction is detected, it could mean, for example, that the compact starter has reached the end of its service life.

-

Page 140: Replacing The Sirius 3Ra6 Compact Starter

Service 13.4 Replacing the SIRIUS 3RA6 compact starter 13.4 Replacing the SIRIUS 3RA6 compact starter When service work becomes necessary or there is a malfunction (e.g. end of service life reached), the SIRIUS 3RA6 compact starter will need to be replaced. The permanent wiring means that the main conductor terminals will be disconnected automatically when the compact starter is removed.

-

Page 141

Service 13.4 Replacing the SIRIUS 3RA6 compact starter Requirements when the compact starter is installed on a DIN rail or level surface (screw fastening) DANGER Danger, high voltage! Electrical voltage can result in electric shocks or burns. Before starting work, disconnect the system and devices from the power supply. ●… -

Page 142: Order Numbers

Service 13.5 Order numbers 13.5 Order numbers 13.5.1 Order numbers for the SIRIUS 3RA6 compact starter Overview of order numbers The SIRIUS 3RA6 compact starter order number is made up of a fixed series of characters plus a number of variables (①, ②, ③, ④ and ⑤): 3RA6 ①…

-

Page 143: Order Numbers For Accessories

Service 13.5 Order numbers Example Options 3RA6 ① 0 — ② ③ ④ ⑤ SIRIUS 3RA6 compact starter Compact starter: Direct starter version ① ➜ 12 Terminal connection type All terminals with screw-type connection technology ② ➜ 1 Current setting range 1 to 4 A ③…

-

Page 144: With Screw-Type

Service 13.5 Order numbers SIRIUS infeed system for 3RA6 System component Order number Left infeed, 50/70 mm² screw terminal with three slots, outgoing terminals with — Screw-type connection technology 3RA6813-8AB — Spring-loaded connection technology 3RA6813-8AC Incl. PE bar (for installing Type E starters in accordance with UL 508) Left infeed, 25/35 mm²…

-

Page 145

Service 13.5 Order numbers 3-phase busbar System component Order number 3-phase busbar — 2 partitions 3RV1915-1AB — 3 partitions 3RV1915-1BB — 4 partitions 3RV1915-1CB — 5 partitions 3RV1915-1DB 3-phase infeed terminal, 3RV1915-5B connection from the bottom, with screw-type connection technology Connection piece 3RV1915-5DB for connecting compact starters to size S00 circuit breakers… -

Page 146

Service 13.5 Order numbers SIRIUS 3RA6 Compact Starter System Manual, 02/2008, GWA 4NEB 560 0601-02 DS 02… -

Page 147: Technical Data

Technical data 14.1 SIRIUS 3RA6 compact starter General technical data Order number 3RA61 3RA62 Device standard IEC / EN 60947-6-2 Number of poles Permissible ambient temperature Storage According to IEC / EN 60721-3-1 °C -55 to +80 Shipping According to IEC / EN 60721-3-2 °C -55 to +80 Operation…

-

Page 148

Technical data 14.1 SIRIUS 3RA6 compact starter Order number 3RA61 3RA62 Power loss P of all 0.1 … 0.4 A v max main current paths 0.32 … 1.25 A 19.1 in accordance with rated current I 1 … 4 A (top setting range) 3 … -

Page 149

Technical data 14.1 SIRIUS 3RA6 compact starter Order number 3RA61 3RA62 Surge suppressor Varistor (ready-integrated) Degree of pollution Safe isolation According to IEC / EN 60947-1 Control circuit to internal auxiliary circuit Internal auxiliary/control circuit to internal auxiliary/control circuit Internal auxiliary/control circuit to external auxiliary circuit Main circuit to internal auxiliary circuit Main circuit to external auxiliary circuit Max. -

Page 150

Technical data 14.1 SIRIUS 3RA6 compact starter Order number 3RA61 3RA62 24 V, DC operation — Up to 12 A Holding current Active power 2.45 Apparent power 2.75 cos φ 0.88 — 8 to 32 A Holding current Active power Apparent power cos φ… -

Page 151

Technical data 14.1 SIRIUS 3RA6 compact starter Order number 3RA61 3RA62 Holding current and holding power valid for working range 110 V to 240 V 110 V, AC operation — Up to 12 A Holding current Active power Apparent power cos φ… -

Page 152

Technical data 14.1 SIRIUS 3RA6 compact starter Main circuit Order number 3RA61 3RA62 Switching frequency At AC-41 At AC-43 Making capacity 12 x I Breaking capacity 10 x I Service life — Mechanical endurance Switching cycles 10 million — Electrical endurance Switching cycles 1.52 million (I = 0.9 I… -

Page 153

Technical data 14.1 SIRIUS 3RA6 compact starter Order number 3RA61 3RA62 3RA691.-.A Service life External auxiliary switch block, internal auxiliary switch — Mechanical endurance Switching cycles 10 million — Electrical endurance AC-15, 230 V At 6 A Switching cycles 200,000 At 3 A Switching cycles 500,000… -

Page 154

Technical data 14.1 SIRIUS 3RA6 compact starter Order number 3RA61 3RA62 3RA691.-.A Short-circuit protection Short circuit signaling switch Fuse links gL/gG NEOZED 5SE, DIAZED 5SB, NH 3NA ≤ 1.1 kA) Miniature circuit breakers up to 230 V with C characteristic Short-circuit current I <… -

Page 155

Technical data 14.1 SIRIUS 3RA6 compact starter Conductor cross-sections of main conductor terminals Order number 3RA6920-1A 3RA6920-2A Type of connection Screw connection Spring-loaded connection Rated current I … 12 A 8 … 32 A … 12 A 8 … 32 A Tool Pozidriv, size 2 Pozidriv, size 2… -

Page 156

Technical data 14.1 SIRIUS 3RA6 compact starter Conductor cross-sections of external auxiliary switch block for compact starter Order number 3RA691.-1A 3RA691.-1A Type of connection Screw connection Spring-loaded connection Tool Pozidriv, size 2 8WA2 807 (2.5 x 0.4) mm Specified tightening torque 0.8 … -

Page 157: As-I Mounting Module

Technical data 14.2 AS-i mounting module 14.2 AS-i mounting module General technical data Order number 3RA6970-3A 3RA6970-3B Permissible ambient temperature Storage/shipping According to IEC / EN 60721-3-1 °C -25 to +70 (storage), IEC / EN 60721-3-2 (shipping) Degree of protection According to IEC / EN 60947-1 IP20 EMC interference immunity…

-

Page 158: Sirius Infeed System For 3Ra6

Technical data 14.3 SIRIUS infeed system for 3RA6 14.3 SIRIUS infeed system for 3RA6 General data Order number 3RA68. Frequency 50/60 Hz Permissible ambient temperature Storage / transport °C -55 … +80 operation °C -20 … +60 Permissible rated current of compact starter at the following internal control cabinet temperatures: + 40 °C…

-

Page 159

Technical data 14.3 SIRIUS infeed system for 3RA6 Order number 3RA68. Short-circuit protection for screw-type infeed 3RV1041-3MA10 (25/35 mm ) and NH gL/gG 3NA3, 315 A screw-type infeed (50/70 mm Short-circuit protection for terminal block 1.5 mm² < 7.5 kA d,max 2.5 mm²… -

Page 160

Technical data 14.3 SIRIUS infeed system for 3RA6 Conductor cross-sections of spring-loaded infeed (L1, L2, L3) and PE infeed, 25/35 mm , with spring-loaded connection technology Order number 3RA6830-5AC, 3RA6860-5AC Type of connection Spring-loaded connection Tool 8WA2 806 (5.5 x 0.8 mm) Conductor cross-sections Solid, stranded 4 … -

Page 161: With Spring-Loaded Connection Technology

Technical data 14.3 SIRIUS infeed system for 3RA6 Conductor cross-sections of PE tap, 6/10 mm , with spring-loaded connection technology Order number 3RA6870-3AC Type of connection Spring-loaded connection Tool 8WA2 803 (3.5 x 0.5) mm Conductor cross-sections Solid 1,5 … 10 Finely stranded without end sleeve 1,5 …

-

Page 162

Technical data 14.3 SIRIUS infeed system for 3RA6 SIRIUS 3RA6 Compact Starter System Manual, 02/2008, GWA 4NEB 560 0601-02 DS 02… -

Page 163: Dimension Drawings

Dimension drawings 15.1 SIRIUS 3RA6 compact starter 15.1.1 Dimensions (in mm) 3RA6 compact starter (screw-type connection technology) Figure 15-1 Side view of the 3RA6 compact starter (screw-type connection technology) Push-in lug for screw fastening Adapter for screw fastening SIRIUS 3RA6 Compact Starter System Manual, 02/2008, GWA 4NEB 560 0601-02 DS 02…

-

Page 164: Figure 15-2 Side View Of The 3Ra6 Compact Starter (Spring-Loaded Connection Technology)

Dimension drawings 15.1 SIRIUS 3RA6 compact starter 3RA6 compact starter (spring-loaded connection technology) Figure 15-2 Side view of the 3RA6 compact starter (spring-loaded connection technology) Push-in lug for screw fastening Adapter for screw fastening SIRIUS 3RA6 Compact Starter System Manual, 02/2008, GWA 4NEB 560 0601-02 DS 02…

-

Page 165: Minimum Distances From Neighboring Components (Dimensions In Mm)

Dimension drawings 15.1 SIRIUS 3RA6 compact starter 15.1.2 Minimum distances from neighboring components (dimensions in mm) Distance from neighboring components When installing compact starters, the following distances from grounded or live parts and from neighboring components must be observed in accordance with IEC / EN 60947-6-2. Note The lateral distances are minimum distances from grounded components.

-

Page 166: Sirius Infeed System For 3Ra6

Dimension drawings 15.2 SIRIUS infeed system for 3RA6 15.2 SIRIUS infeed system for 3RA6 15.2.1 Dimensions (in mm) 3RA6813-8AB Figure 15-3 Dimension drawing of screw-type infeed (50/70 mm ) featuring outgoing terminals with screw-type connection technology 3RA6812-8AB Figure 15-4 Dimension drawing of screw-type infeed (25/35 mm ) featuring outgoing terminals with screw-type connection technology 3RA6 compact starter…

-

Page 167

Dimension drawings 15.2 SIRIUS infeed system for 3RA6 3RA6813-8AC Figure 15-5 Dimension drawing of screw-type infeed (50/70 mm ) featuring outgoing terminals with spring-loaded connection technology 3RA6812-8AC Figure 15-6 Dimension drawing of screw-type infeed (25/35 mm ) featuring outgoing terminals with spring-loaded connection technology 3RA6 compact starter SIRIUS 3RA6 Compact Starter… -

Page 168: Figure 15-7 Dimension Drawing Of Spring-Loaded Infeed

Dimension drawings 15.2 SIRIUS infeed system for 3RA6 3RA6830-5AC Figure 15-7 Dimension drawing of spring-loaded infeed 3RA6823-0AC, 3RA6822-0AC Figure 15-8 Dimension drawing of extension blocks featuring outgoing terminals with spring-loaded connection technology SIRIUS 3RA6 Compact Starter System Manual, 02/2008, GWA 4NEB 560 0601-02 DS 02…

-

Page 169: Figure 15-9 Dimension Drawing Of Extension Blocks Featuring Outgoing Terminals With Screw-Type Connection Technology

Dimension drawings 15.2 SIRIUS infeed system for 3RA6 3RA6823-0AB, 3RA6822-0AB Figure 15-9 Dimension drawing of extension blocks featuring outgoing terminals with screw-type connection technology SIRIUS 3RA6 Compact Starter System Manual, 02/2008, GWA 4NEB 560 0601-02 DS 02…

-

Page 170: Minimum Distances From Neighboring Components (Dimensions In Mm)

Dimension drawings 15.2 SIRIUS infeed system for 3RA6 15.2.2 Minimum distances from neighboring components (dimensions in mm) Distance from neighboring components When installing the infeed system for 3RA6, the following distances from neighboring parts must be observed. Figure 15-10 Distances from neighboring components (infeed system for 3RA6) Note The lateral distances are minimum distances from grounded components.

-

Page 171: Circuit Diagrams

Circuit diagrams 16.1 Main circuit of 3RA6 compact starter 3RA61 compact starter direct starter 3RA6911 .A 33 43 1L1 3L2 5L3 98 96 34 44 3RA6912 .A 13 21 31 41 14 22 32 42 3RA6913 .A 31 43 32 44 2T1 4T2 6T3 Figure 16-1 Main circuit of 3RA61 compact starter direct starter…

-

Page 172

Circuit diagrams 16.1 Main circuit of 3RA6 compact starter 3RA62 compact starter reversing starter 1L1 3L2 5L3 98 96 3RA6911 .A 3RA6911 .A 53 63 23 33 24 34 54 64 3RA6912 .A 3RA6912 .A 51 61 21 31 52 62 22 32 3RA6913 .A 3RA6913 .A… -

Page 173: Control Circuit For 3Ra6 Compact Starter

Circuit diagrams 16.2 Control circuit for 3RA6 compact starter 16.2 Control circuit for 3RA6 compact starter 3RA61 compact starter direct starter Figure 16-3 Control circuit of 3RA61 compact starter direct starter Pushbutton switch control Maintained-contact operation Overload release, breaker latching mechanism SIRIUS 3RA6 Compact Starter System Manual, 02/2008, GWA 4NEB 560 0601-02 DS 02…

-

Page 174

Circuit diagrams 16.2 Control circuit for 3RA6 compact starter 3RA62 compact starter reversing starter Figure 16-4 Control circuit of 3RA62 compact starter reversing starter Pushbutton switch control Maintained-contact operation Overload release, breaker latching mechanism SIRIUS 3RA6 Compact Starter System Manual, 02/2008, GWA 4NEB 560 0601-02 DS 02… -

Page 175: Appendix

In addition to this manual, please refer to the operating instructions and manuals for any accessories. You can download the relevant documentation from the Internet (www.siemens.de/automation/csi/manual). Simply enter the order number of the relevant item into the search field. Operating instructions…

-

Page 176: List Of Abbreviations

Appendix A.2 List of abbreviations List of abbreviations Abbreviation/Symbol Term Conductor, solid and stranded Conductor, finely stranded without end sleeve Conductor, finely stranded with end sleeve LED not illuminated LED illuminated green No mechanical display Mechanical display is white Screw-type infeed (50/70 mm Left infeed, 50/70 mm²…

-

Page 177: Glossary

Glossary 3-phase busbar The 3-phase busbar enables several compact starters to be fed using a single infeed terminal. 8US busbar adapter The 8US busbar adapter enables the compact starter to be mechanically fastened and electrically connected to a busbar system. Adapter for screw fastening The adapters for screw fastening enable you to install the compact starter on a level surface.

-

Page 178

Glossary Motor model The electronics calculate the motor temperature continuously in accordance with the operating time and current load and store this information in a thermal motor model. Process image The process image is used for buffering input and output data. When the control system starts cyclic program execution, the signal states of the compact starter are transferred to the process input image of the higher-level control system. -

Page 179: Index

Index Auxiliary switch block for compact starter, 94 Compact starter, 71, 72 Infeed system for 3RA6, 114 Limit switch, 78 3-phase busbar, 14, 34, 117 Terminal for Type E, 128 3-phase infeed terminal, 120 Configuration 3RA19 infeed system, 106 3-phase busbar, 118 3RA61 compact starter direct starter, 41 Control circuit, 15 3RA62 compact starter reversing starter, 44…

-

Page 180

Index Coding, 97 Stripping lengths, 112 Rated current Isolating features, 11 3-phase busbar, 34, 117 Infeed system for 3RA6, 28 Reset Auto reset, 53, 54, 81 Limit switch, 78 Manual reset, 53, 54, 81 Reversing starter, 44 Main conductor terminal block, 133, 134 Main switch and EMERGENCY STOP function, 12 Screw terminal, 73, 79 Manual reset, 53, 54, 81… -

Page 182

Siemens AG Automation and Drives Low-Voltage Controls and Distribution Postfach 48 48 90327 NUERNBERG GERMANY www.siemens.com/compactstarter 3RA6992-0A…

- Небольшие размеры;

- Простота в использовании;

- Простота монтажа и обслуживания;

- Полупроводниковая защита от перегрузки;

- Внутренняя защита устройства;

- Настраиваемое ограничение тока;

- Встроенная шунтирующая контактная система для минимизации потерь энергии;

- Широкий диапазон температуры от -25 до + 60 °C;

|

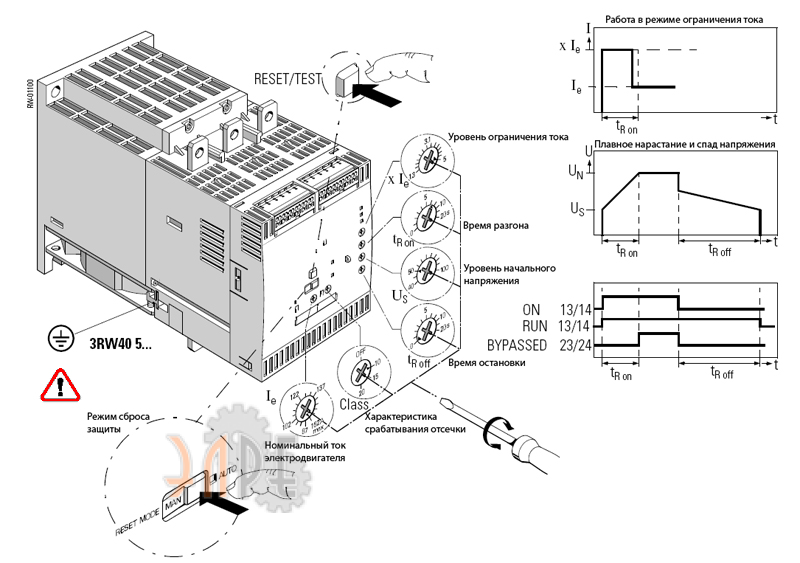

Мощность электродвигателя Рн, кВт, Uпит=380 В, 3Ф |

Ток номинальный, А |

Код устройства |

Масса, кг |

|

|

Двигателя |

УПП |

|||

|

5,5 |

10.4 |

12,5 |

3RW4024-1BB14 |

0,8 |

|

7,5 |

13.8 |

25 |

3RW4026-1BB14 |

0,8 |

|

11 |

20.0 |

|||

|

15 |

26.5 |

32 |

3RW4027-1BB14 |

0,8 |

|

18,5 |

32.0 |

38 |

3RW4028-1BB14 |

0,8 |

|

22 |

40.5 |

45 |

3RW4036-1BB14 |

1,4 |

|

30 |

54.0 |

63 |

3RW4037-1BB14 |

1,4 |

|

37 |

65.0 |

72 |

3RW4038-1BB14 |

1,4 |

|

45 |

79.0 |

80 |

3RW4046-1BB14 |

1,9 |

|

55 |

96.0 |

106 |

3RW4047-1BB14 |

1,9 |

|

75 |

130 |

134 |

3RW4055-6BB44 |

5 |

|

90 |

154 |

162 |

3RW4056-6BB44 |

7 |

|

110 |

190 |

230 |

3RW4073-6BB44 |

9 |

|

132 |

225 |

|||

|

160 |

265 |

280 |

3RW4074-6BB44 |

9 |

|

200 |

325 |

356 |

3RW4075-6BB44 |

5 |

|

250 |

415 |

432 |

3RW4076-6BB44 |

7 |

Рекомендуется для работы в составе:

- Вентиляторы

- Насосы

- Строительные машины

- Прессы

- Эскалаторы

- Транспортеры

- Системы кондиционирования воздуха

- Сборочные линии

- Компрессоры и охладители

- Рабочие механизмы

- Мешалки

- Центрифуги

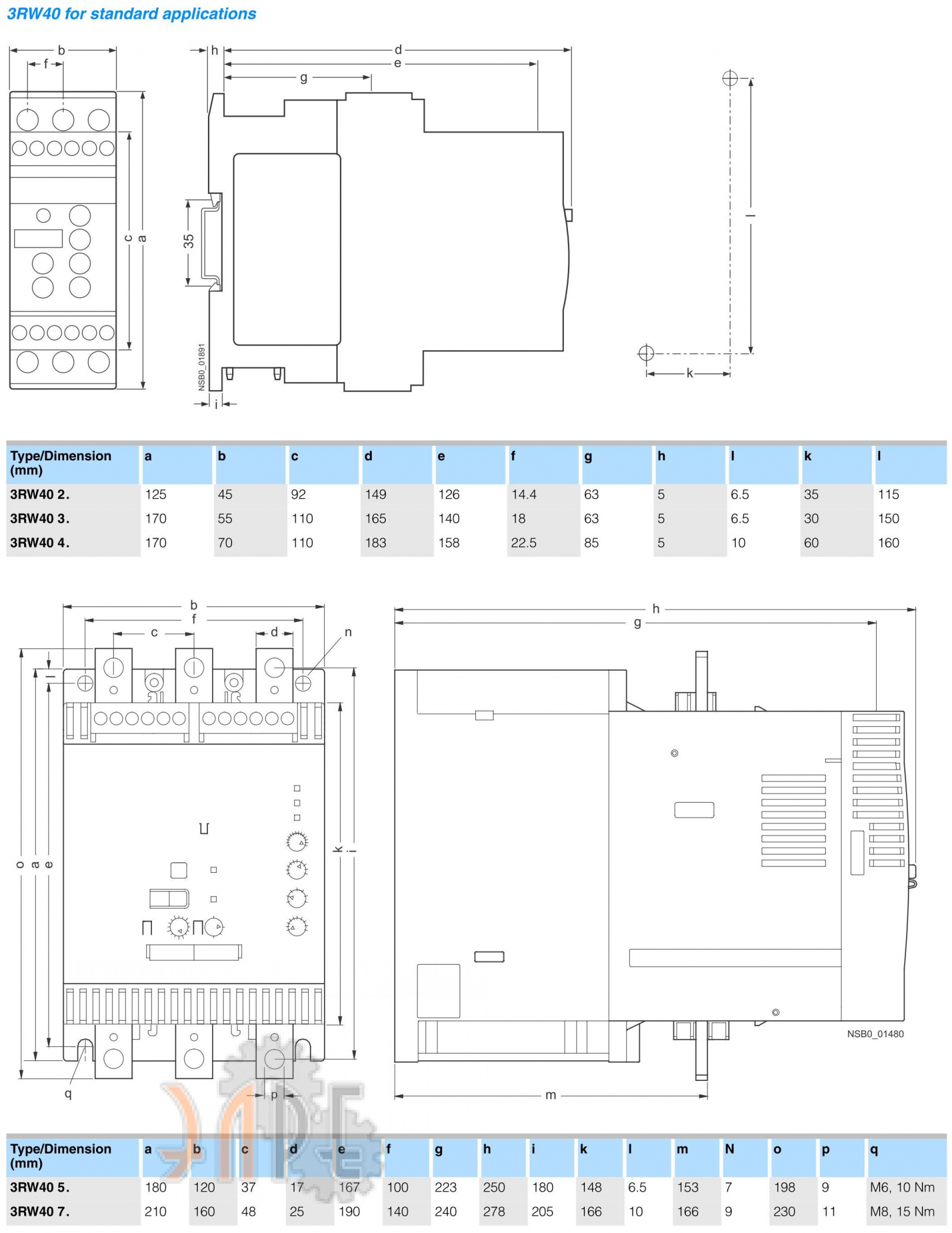

Устройство плавного пуска SIRIUS 3RW40 оснащено встроенной шунтирующей контактной системой, которая снижает потери электроэнергии во время работы, в результате чего составные элементы не перегреваются. 4-шаговый поворотный переключатель позволяет устанавливать время отключения при перегрузке.

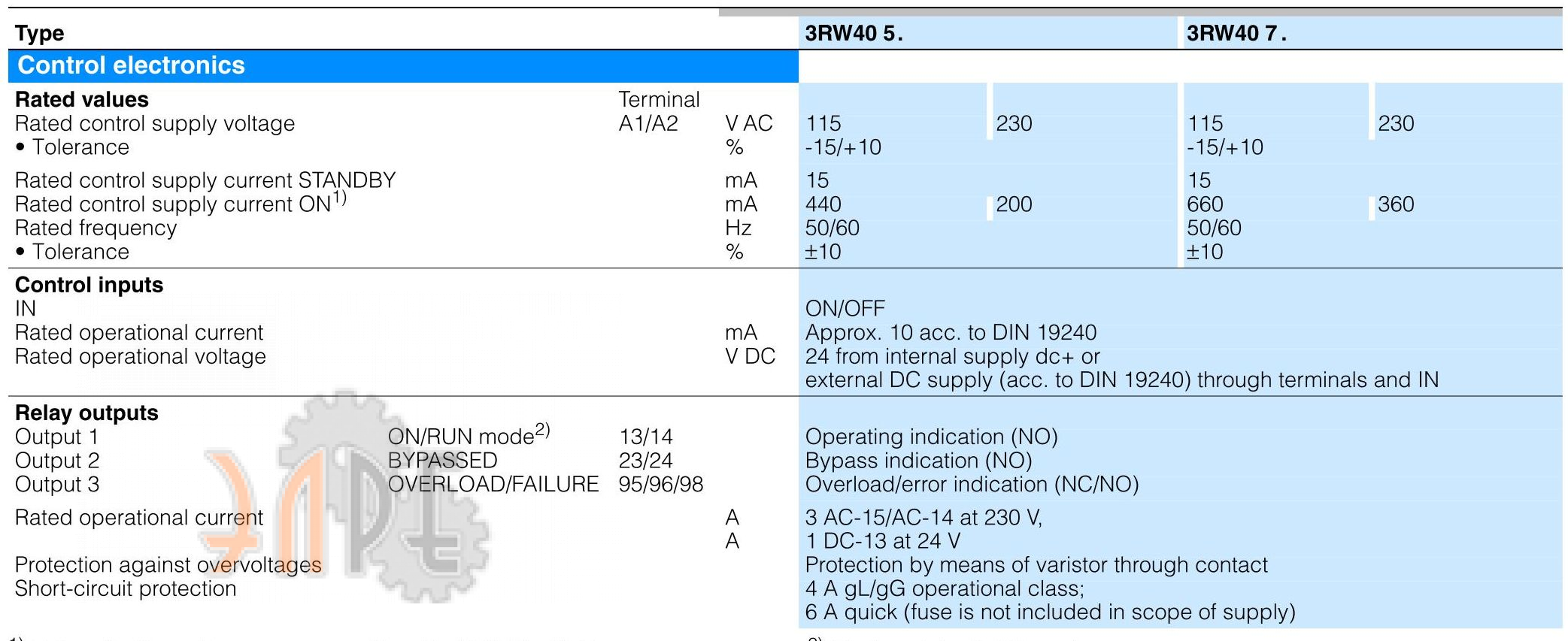

Рабочие параметры Siemens Sirius 3RW4076-6BB44

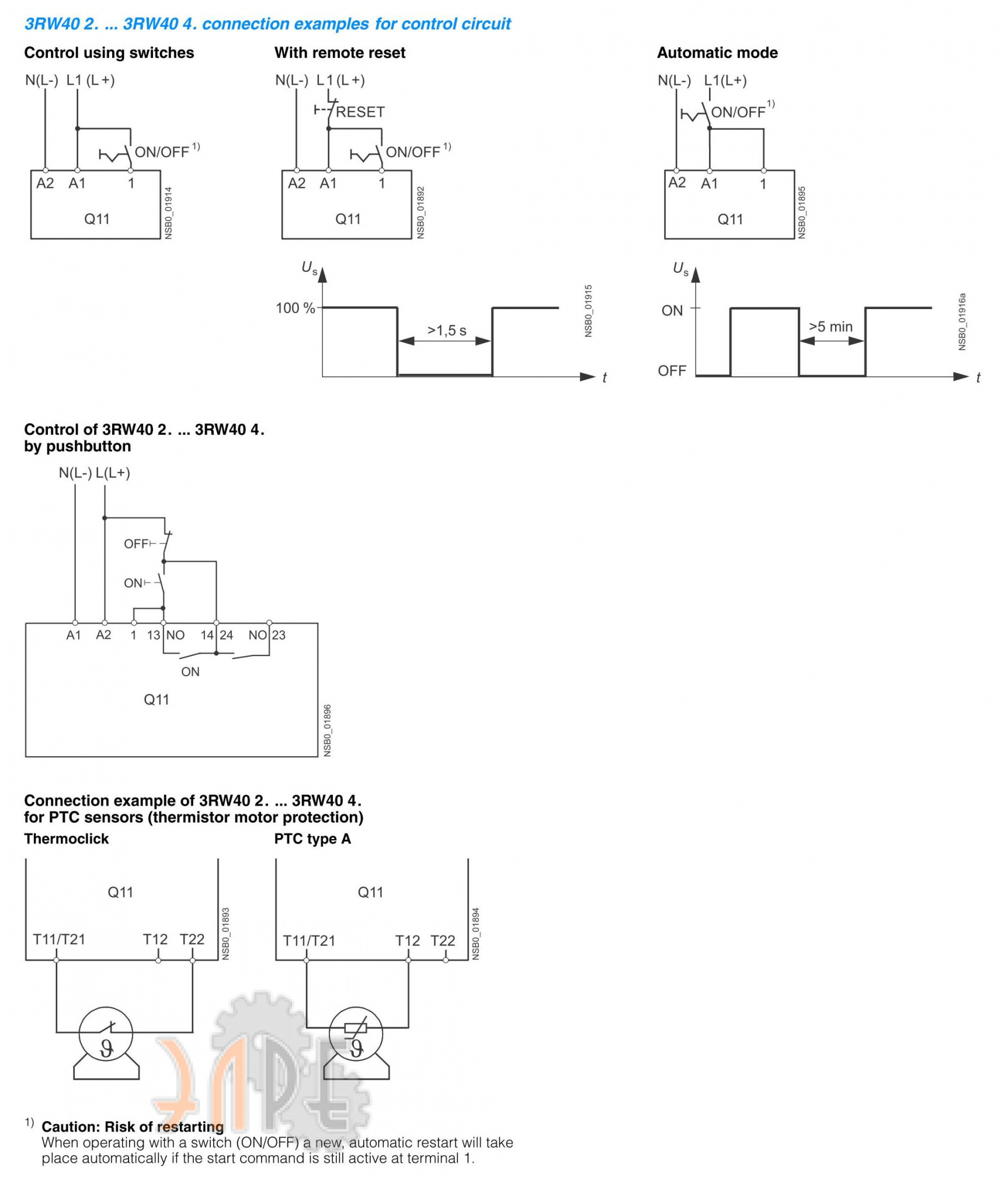

Варианты исполнения и применения Siemens Sirius 3RW40

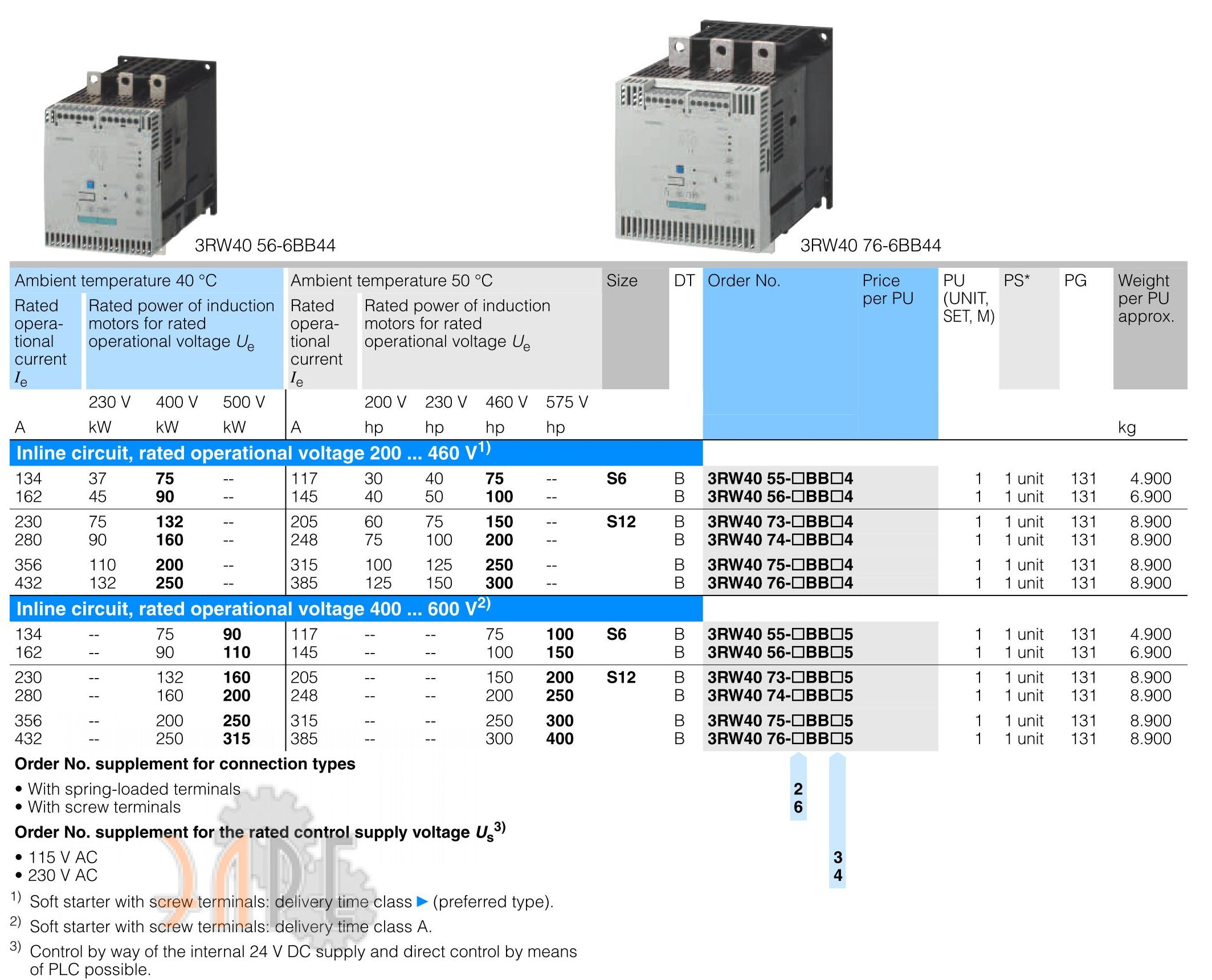

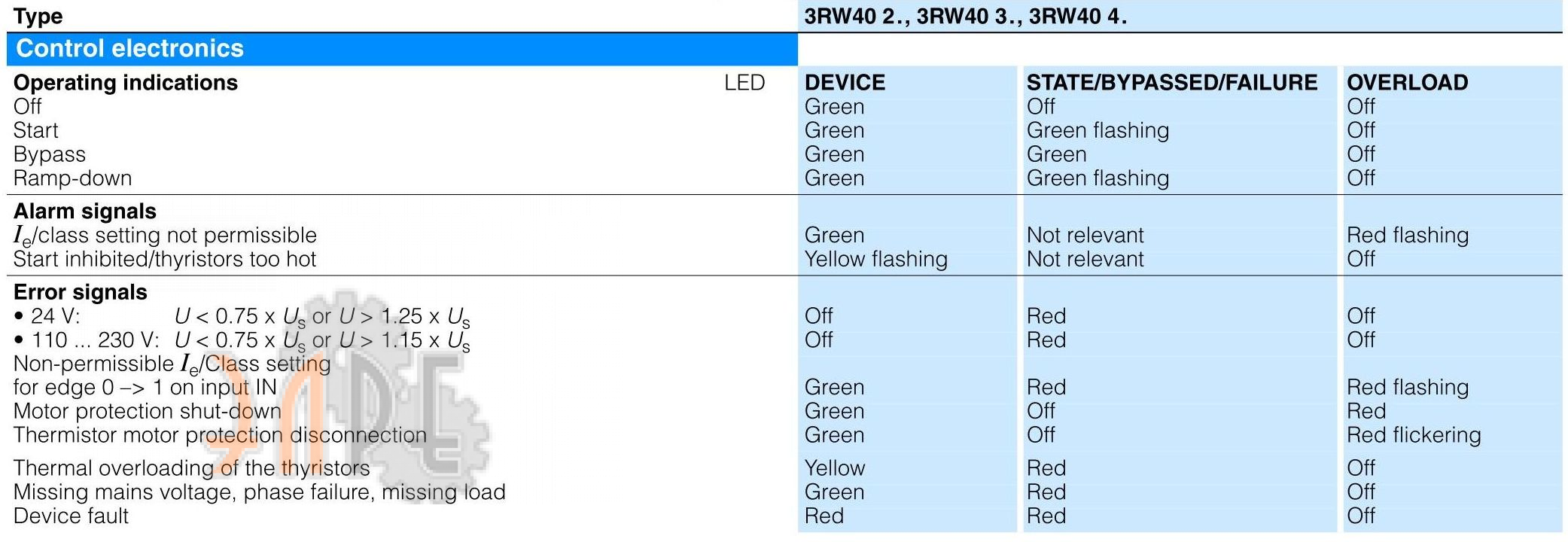

Электроника управления и силовая

Варианты схем управления и подключения Siemens 3RW4076-6BB44

Примеры включения в главную цепь

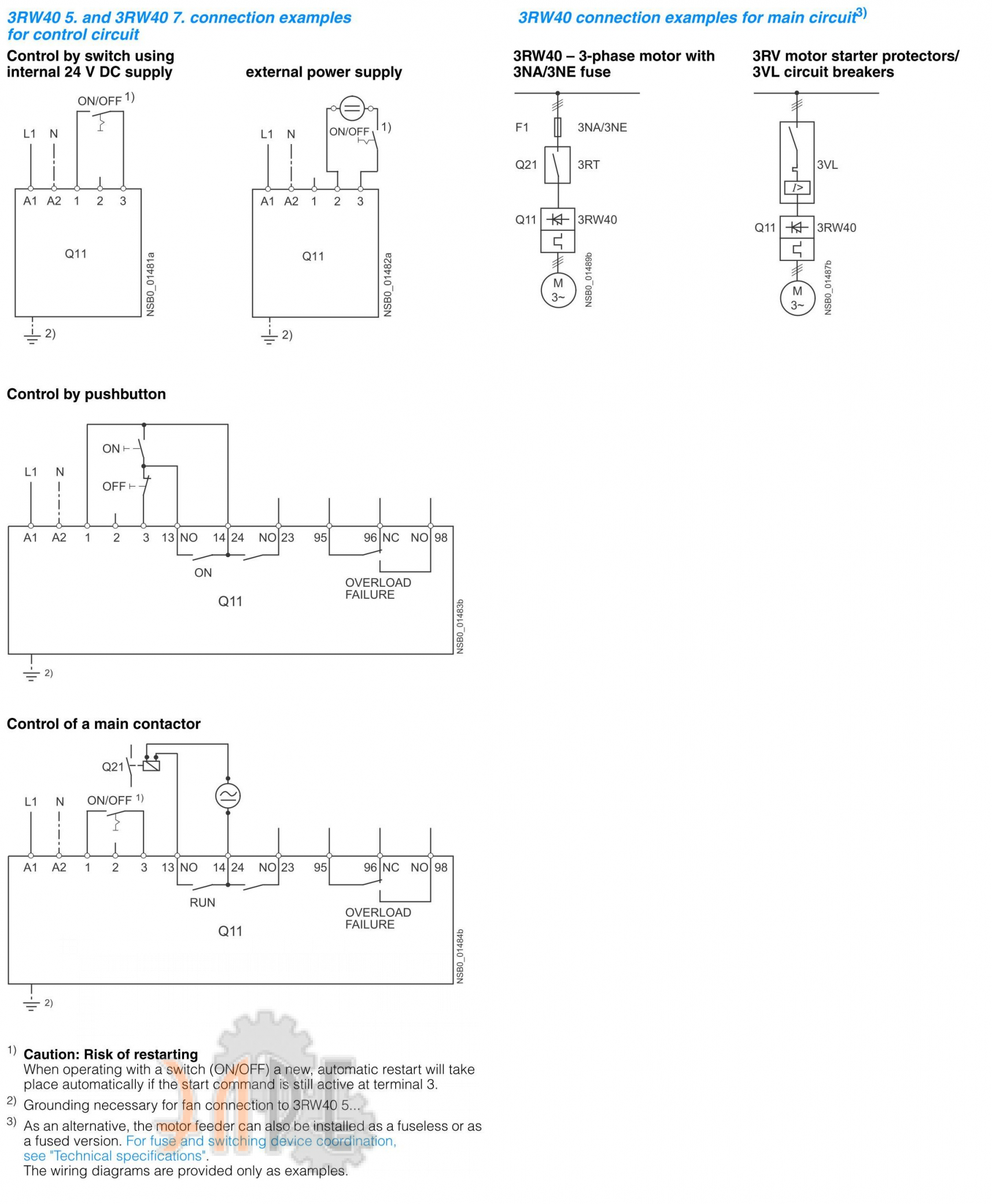

Габаритные размеры Siemens Sirius 3RW4076-6BB44

Упраление и эксплуатации устройства

Рекомендуемые режимы работы

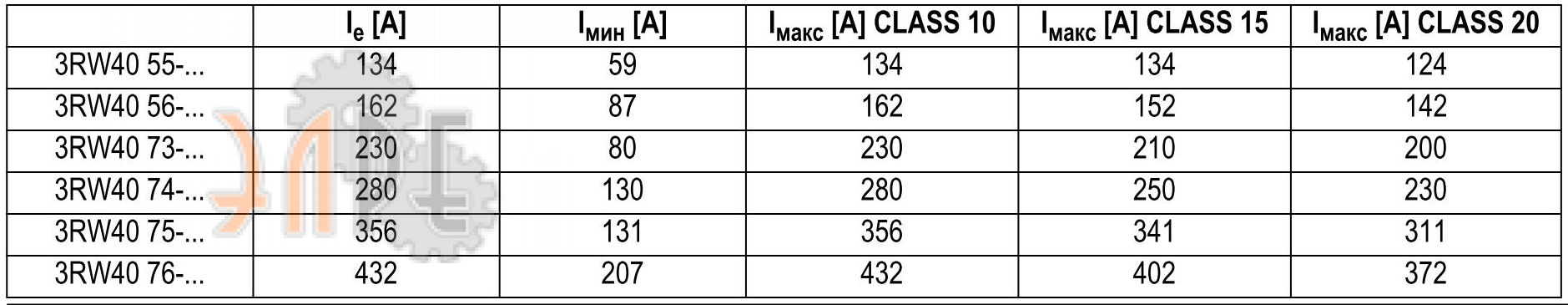

Допустимые установленные значения тока в двигателя

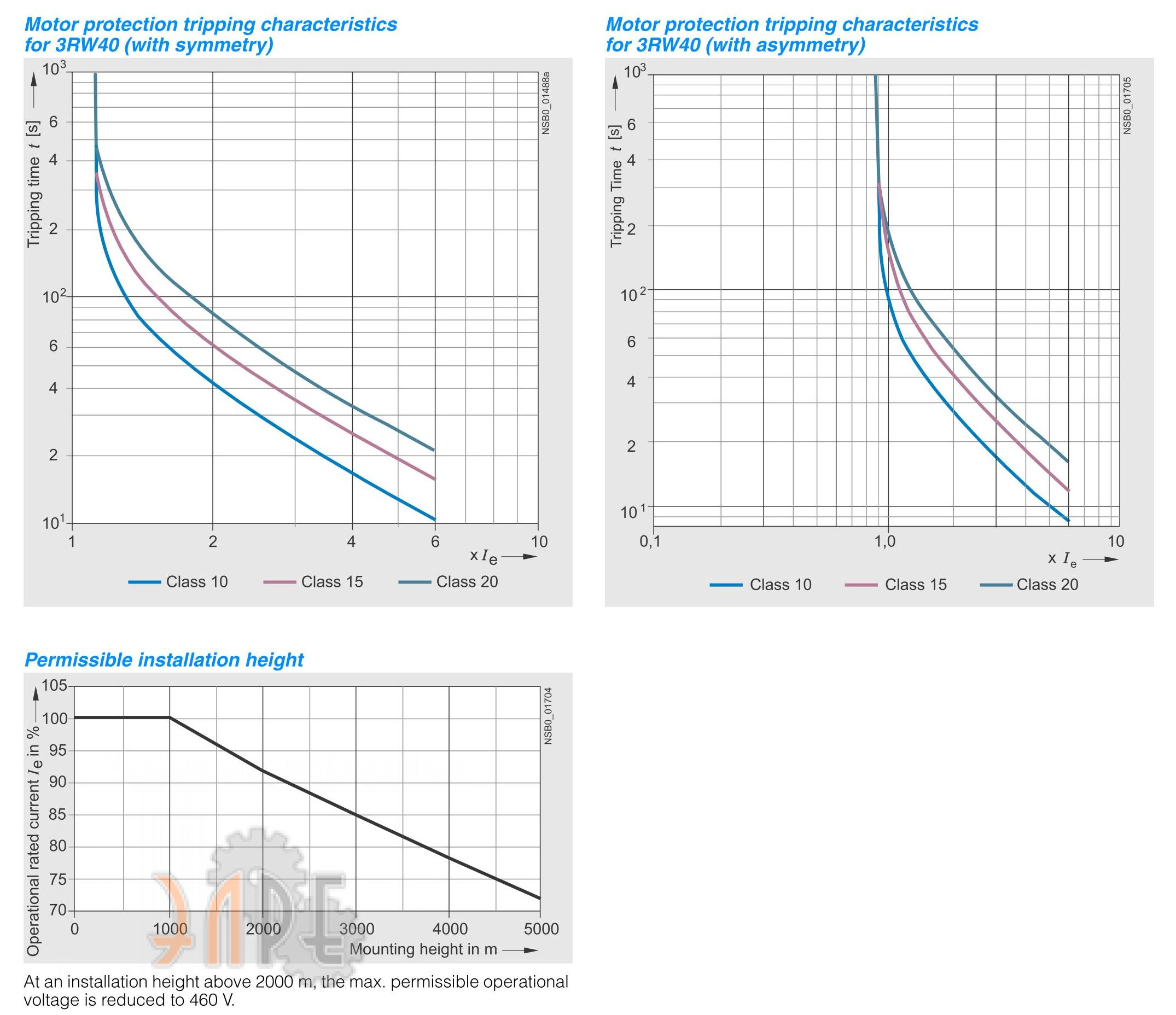

Кривые характеристик срабатывания

Модельный ряд устройств плавного пуска Siemens Sirius серии 3RW

Устройства плавного пуска SIRIUS 3RW40 обладают такими же преимуществами, как и 3RW30/31, но дополнительно оснащены функциями, уникальными в данном диапазоне мощности: полупроводниковая защита от перегрузки двигателя и встроенная защита устройства, регулируемые ограничения тока и двухфазный метод управления (баланс полярности). Устройства плавного пуска SIRIUS 3RW40 являются частью модульной системы SIRIUS. В результате этого, они имеют идентичные размеры и схемы подключения. Благодаря своим особо компактным размерам, устройства плавного пуска SIRIUS 3RW40 занимают в два раза меньше пространства в шкафу управления по сравнению с устройствами пуска «звезда-треугольник» Устройства плавного пуска SIEMENS серии SIRIUS 3RW40 мощностью до 250 кВт (при 400 В) примняются в 3-фазных сетях и предназначены для плавного пуска/остановки 3-фазных асинхронных двигателей. Применение этих устройств плавного пуска обеспечивает отсутствие бросков тока и вращающего момента, которые возникают при использовании устройств пуска «звезда-треугольник».

SIRIUS

Sanftstarter 3RW40

Soft starter 3RW40

Démarreur progressif 3RW40

Arrancador suave 3RW40

Avviatore dolce 3RW40

Chave de partida suave 3RW40

Yumuşak yol verici 3RW40

Устройство плавного пуска 3RW40

软启动器 3RW40

Sanftstarter 3RW40

DE

Betriebsanleitung — Bestell-Nr.: 3ZX1012-0RW40-1AA1

Grafiken

Sicherheits- und Inbetriebnahmehinweise für explosionsgefährdete Bereiche — Bestell-Nr.: 3ZX1012-0RW40-1CA1

Soft starter 3RW40

EN

Operating Instructions — Order No.: 3ZX1012-0RW40-1AA1

Graphics

Safety and commissioning instructions for hazardous areas — Order No.: 3ZX1012-0RW40-1CA1

Démarreur progressif 3RW40

FR

Instructions de service — N° de référence : 3ZX1012-0RW40-1AA1

Graphiques

Consignes de sécurité et de mise en service pour les zones explosibles — N° de référence : 3ZX1012-0RW40-1CA1

Arrancador suave 3RW40

ES

Instructivo — Referencia: 3ZX1012-0RW40-1AA1

Gráficos

Instrucciones de seguridad y puesta en servicio en entornos con peligro de explosión — Referencia: 3ZX1012-0RW40-1CA1

Avviatore dolce 3RW40

IT

Istruzioni operative — N° di ordinaz.: 3ZX1012-0RW40-1AA1

Grafiche

Indicazioni di sicurezza e per la messa in servizio in aree con pericolo d’esplosione — N° di ordinaz.: 3ZX1012-0RW40-1CA1

Chave de partida suave 3RW40

PT

Instruções de Serviço — Nº de enc.: 3ZX1012-0RW40-1AA1

Gráficos

Indicações de segurança e de colocação em funcionamento para áreas apresentando risco de explosão —

Nº de enc.: 3ZX1012-0RW40-1CA1

Yumuşak yol verici 3RW40

TR

İşletme kılavuzu — Sipariş no.: 3ZX1012-0RW40-1AA1

Grafikler

Patlama tehlikesi altında bulunan bölgeler için emniyet ve hizmete alma bilgileri — Sipariş no.: 3ZX1012-0RW40-1CA1

Устройство плавного пуска 3RW40

PY

Инструкция по эксплуатации — № заказа: 3ZX1012-0RW40-1AA1

Графики

Указания по технике безопасности и вводу в эксплуатацию во взрывоопасных зонах — № заказа: 3ZX1012-0RW40-1CA1

软启动器 3RW40

操作规程 — 订货号:3ZX1012-0RW40-1AA1

中文

图表

用于受爆炸威胁区域的安全及首次启动运行说明 — 订购编号 : 3ZX1012-0RW40-1CA1

www.siemens.com/lowvoltage/manuals

SIRIUS-Systemhandbuch / SIRIUS system manual : http://www.siemens.de/sirius-systemhandbuch

Technical Assistance: Telephone: +49 (0) 911-895-5900 (8°° — 17°° CET)

E-mail:

Internet:

GWA 4NEB 535 2193-60 DS 01

technical-assistance@siemens.com

www.siemens.de/lowvoltage/technical-assistance

EN/IEC 60947-4-2

和 29 — 36 页

Fax: +49 (0) 911-895-5907

Last update: 08 October 2009

3RW40 5

3RW40 7

Seite

2 — 4

29 — 36

Page

5 — 7

29 — 36

Page

8 — 10

29 — 36

Página

11 — 13

29 — 36

Pagina

14 — 16

26 — 36

Página

17 — 19

29 — 36

Sayfa

20 — 22

29 — 36

Cтраница

23 — 25

29 — 36

第 26 — 28

SIRIUS

Sanftstarter

Soft starter

agodny rozruch

Arrancador suave

Avviatore dolce

Chave de partida suave

Betriebsanleitung

Operating Instructions

Instructivo

Istruzioni di servizio

Vor der Installation, dem Betrieb oder der Wartung des Geräts muss diese Anleitung gelesen und verstanden werden.

Read and understand these instructions before installing, operating, or maintaining the equipment.

Przeczytaj i zrozum poni sz instrukcj przed monta em, uruchomieniem i eksploatacj .

Leer y comprender este instructivo antes de la instalación, operación o mantenimiento del equipo.

Leggere con attenzione questi istruzioni prima di installare, utilizzare o eseguire manutenzione su questa apparecchiatura.

Ler e compreender estas instruções antes da instalação, operação ou manutenção do equipamento.

GEFAHR

!

Gefährliche Spannung. Lebensgefahr

oder Gefahr schwerer Verletzung.

Vor Beginn der Arbeiten Anlage und

Gerät spannungsfrei schalten.

!

PELIGRO

Tensión peligrosa.

Puede causar la muerte o lesiones

graves.

Desconectar la alimentación eléctrica

antes de trabajar en el equipo.

Eine sichere Gerätefunktion ist nur mit zertifizierten Komponenten gewährleistet.

Reliable functioning of the equipment is only ensured with certified components.

Niezawodne funkcjonowanie urz dzenia jest zapewnione tylko z autoryzowanymi komponentami.

El funcionamiento seguro del aparato sólo está garantizado con componentes certificados.

Il funzionamento sicuro dell’apparecchiatura viene garantito soltanto con componenti certificati.

O funcionamento seguro do aparelho apenas pode ser garantido se forem utilizados os componentes certificados.

Gefährliche Spannung.

Lebensgefahr oder schwere Verletzungsgefahr.

Um elektrischen Stro m sc hlagoder Verbrennungen zu

vermeiden, dürfen die Kl em m en des Motorsteuergeräts nicht

berührt werden, wenn das Gerät mit Spannung versorgt wird.

An den Ausgangskl em me n steht auch im AUS-Zu st and d es

Motorsteuergerä ts S pann ung an.

Niebezpieczne napi cie.

Mo e spowodowa mier lub powa ne obra enia.

Ab y unikn

dotyka zacisków aparatu, kiedy napi cie jest podane na

urz dzenia. Zaciski wyj cio we s pod napi cie m nawet, kiedy

urz dzenie jest wy czone.

Tensione pericolosa.

Può provocare morte o lesioni gravi.

Per evitare pericoli difolgorazione o di ustione, nontoccare i

morsetti dell’avviatore qua ndo l’apparecchiatura è sotto ten-

sione. I morsetti d’uscita sono sotto tensione anche quando

l’avviatore è disinserito.

GWA 4NEB 535 2193-10a

Instukcja obs ugi

Instruções de Serviço

DANGER

!

Hazardous voltage.

Will cause death or serious injury.

Disconnect power before working on