Exterior Appearance

2

Model Code

5

Model Line-Up

6

Front View

7

Rear View

8

Side View

9

Tire & Disc Wheel

10

Interior

11

Instrument Panel

12

Steering Wheel

13

Steering Pad Switch Function

13

Front Seat

14

Rear Seat

15

Luggage

15

Deck under Tray

17

Luggage Cover

17

Equipment

18

Multi Display

18

Navigation System

18

Trip Information

18

Audio System

19

Head Unit Specifications

19

Speaker’s Specification

19

Audio System Location

20

Multi-Information Display

20

Air Conditioner System

22

Power Heater System

22

Windshield & Door Glass

23

Rear Sunshade

24

Power Outlet

24

Wiper System

24

Performance

25

Power Train

25

Transaxle

26

Chassis

27

Front Suspension

27

Rear Suspension

27

Brake

27

Safety

28

SRS (Supplemental Restraint System) Airbag System

28

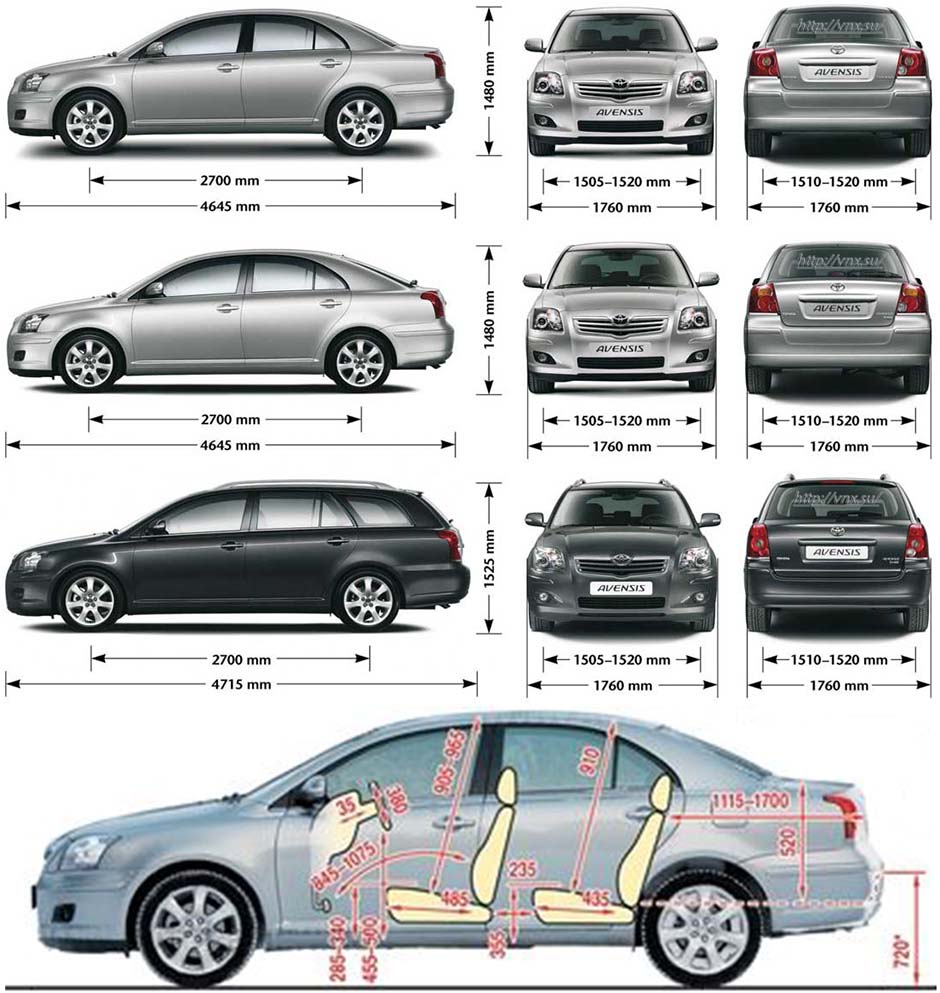

Dimensions

29

Equipment List

30

Major Technical Specifications

33

Electronic Circuit Inspection Procedure

51

Resistance Measuring Condition of Electronic Parts

51

Handling of Connector

51

Connector Checking Points

51

Repair Method of Connector Terminal

52

Handling of Wire Harness

52

Check Open Circuit

52

Check the Continuity

53

Check Short Circuit

54

Check and Replace ECU

55

How to Troubleshoot ECU Controlled Systems

56

For Using Hand-Held Tester

56

Table of Contents

56

Introduction – How to Troubleshoot Ecu Controlled

57

Customer Problem Analysis

59

Symptom Confirmation and Diagnostic Trouble Code

60

ABS with EBD System

60

Symptom Simulation

62

Diagnostic Trouble Code Chart

64

Problem Symptoms Table

65

Circuit Inspection

66

How to Use this Manual

67

Vehicle Identification and Serial Numbers

70

Identification Information

70

Repair Instruction

71

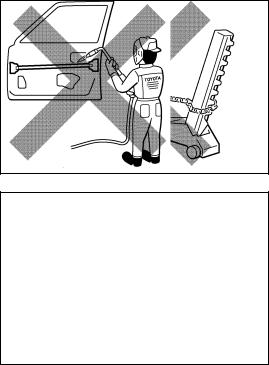

Jacking up and Supporting Vehicle

72

Bolts, Nuts, Screws and Fuses

72

Clips

73

Removal and Installation of Vacuum Hoses

74

For Vehicles Equipped with SRS Airbag and Seat Belt Pretensioner

75

Torque When Using Torque Wrench with Extension Tool

75

Spiral Cable

76

Horn Button Assembly (with Airbag)

76

Instrument Panel Passenger Airbag Assembly

77

Front Seat Airbag Assembly

78

Instrument Panel Lower Airbag Assembly

79

Curtain Shield Airbag Assembly

79

Seat Belt Pretensioner

80

Battery Terminal Removal and Installation

81

Airbag Sensor Assembly

81

SRS Wire Harness and Connector

81

Fuel Control Parts Removal and Installation

82

Engine Intake Parts Removal and Installation

82

Handling of Electronic Parts

82

Handling of Hose Clamps

83

For Vehicles Equipped with Mobile Communication Systems

83

For Vehicles Equipped with Traction Control (TRC) System

83

For Vehicles Equipped with Catalytic Converter

84

Vehicle Lift and Support Locations

85

Notice for Using Swing Arm Type Lift

86

Abbreviations Used in this Manual

87

Glossary of SAE and Toyota Terms

92

Preparation — Audio and Visual System

95

Preparation — Automatic Transmission/Trans

96

Preparation — Brake

100

Preparation — Clutch

102

Preparation — Communication System

103

Preparation — Cooling

104

Preparation — Diagnostics

106

ABS with EBD & BA & TRC & VSC System

107

Preparation — Drive Shaft / Propeller Shaft

108

Preparation — Engine Control System

112

Preparation — Engine Hood/Door

113

Preparation — Engine Mechanical

114

Preparation — Exhaust

123

Preparation — Exterior/Interior Trim

124

Preparation — Front Suspension

125

Preparation — Fuel

126

Preparation — Heater and Air Conditioner

129

Preparation — Ignition

134

Preparation — Instrument Panel/Meter

135

Intake Preparation

136

Preparation — Lubrication

137

Preparation — Manual Transmission/Transaxle

140

Preparation — Parking Brake

143

Preparation — Power Steering

144

Preparation — Rear Suspension

146

Preparation — Seat

148

Preparation — Sliding Roof/Convertible

149

Preparation — Starting and Charging

150

Preparation — Steering Column

151

Preparation — Supplemental Restraint System

152

Preparation — Tire and Wheel

154

Preparation — Vehicle Control System

155

Preparation — Windshield/Window Glass/Mirror

156

Preparation — Wiper and Washer

157

Audio and Visual System Torque Specification

158

Automatic Transmission/Transaxle Service Data

159

Brake Service Data

166

Clutch Service Data

168

Communication System Torque Specification

170

Cooling Service Data

171

Drive Shaft/Propeller Shaft/Axle Service Data

174

Emission Control Service Data

176

Engine Control System Service Data

177

Engine Hood/Door Torque Specification

180

Engine Mechanical Service Data

182

Exhaust Service Data

191

Exterior/Interior Trim Torque Specification

193

Front Suspension Service Data

194

Fuel Service Data

196

Heater and Air Conditioning Service Data

199

Ignition Service Data

201

Instrument Panel/Meter Torque Specification

203

Intake Service Data

204

Lighting Torque Specification

206

Lubrication Service Data

207

Manual Transmission/Transaxle Service Data

210

Parking Brake Service Data

213

Power Steering Service Data

215

Rear Suspension Service Data

217

Seat Torque Specification

219

Seat Belt Torque Specification

220

Sliding Roof/Convertible Torque Specification

221

Standard Bolt — How to Determine Bolt Strength

222

How to Determine Nut Strength

223

Specified Torque for Standard Bolts

224

Starting and Charging Service Data

225

Steering Column Service Data

227

Supplemental Restraint System Torque Specification

229

Tire and Wheel Service Data

230

Windshield/Window Glass/Mirror Torque Specification

231

Wiper and Washer Torque Specification

232

Accelerator Pedal Assy (1AZ–FSE/1CD–FTV) Replacement

233

Camshaft Position Sensor (1CD–FTV) Replacement

234

Crankshaft Position Sensor (1CD–FTV) Replacement

235

Crankshaft Position Sensor (1CD–FTV) Inspection

236

Inspect Mass Air Flow Meter

236

Inspect Intake Shutter Assy

236

Inspect Diesel Engine Coolant Temperature Sensor

237

Inspect Injection or Supply Pump Assy

237

Inspect Diesel Turbo Inlet Air Temperature Sensor

237

Inspect Crankshaft Position Sensor

238

Inspect Camshaft Position Sensor

238

Inspect EDU Relay

238

Inspect EFI Main Relay

239

Inspect Accelerator Pedal Relay

239

ECD System (1CD–FTV) On-Vehicle Inspection

240

Inspect Intake Shutter

240

Inspect Accelerator Pedal Position Sensor

241

ECM Replacement

242

Intake Shutter Assy (1CD–FTV) Components

243

Intake Shutter Assy Removal, Installation, Disassembly, Reassembly

244

Knock Sensor Components

246

Knock Sensor Replacement

250

Knock Sensor (1AZ–FE) Components

253

Knock Sensor (1AZ–FE) Replacement

257

Knock Sensor (1AZ–FSE) Components

260

Knock Sensor (1AZ–FSE) Replacement

265

Knock Sensor (1ZZ–FE/3ZZ–FE) Replacement

267

SFI System Inspection

268

Inspect Throttle Position Sensor

269

Inspect Engine Coolant Temperature Sensor

270

Inspect Knock Sensor

270

Inspect EFI Relay

270

Inspect Circuit Opening Relay

271

SFI System (1AZ–FE) On-Vehicle Inspection

272

Inspect Power Steering Oil Pressure Sensor

272

Inspect Idle Air Control Valve

273

SFI System (1AZ–FSE)

274

Inspect Camshaft Timing Oil Control Valve Assy

274

Inspect Throttle Body Assy

274

SFI System (1AZ–FSE) On-Vehicle Inspection

277

Inspect Throttle Body

278

SFI System (1ZZ–FE/3ZZ–FE) Inspection

279

SFI System (1ZZ–FE/3ZZ–FE) On-Vehicle Inspection

283

Throttle Body Assy (1AZ–FE) Components

285

Throttle Body Assy (1AZ–FE) Removal/Installation/Disassembly

287

Throttle Body Assy (1AZ–FSE)

291

Throttle Body Assy (1AZ–FSE) Replacement

293

Throttle Body Assy (1ZZ–FE) Components

296

Throttle Body Assy (1ZZ–FE) Removal, Installation, Disassembly

298

Throttle Body Assy (3ZZ–FE) Components

302

Throttle Body Assy (3ZZ–FE) Removal, Installation, Disassembly

304

Common Rail Assy (1CD–FTV) Components

306

Common Rail Assy (1CD–FTV) Replacement

308

Fuel Filter Assy (1CD–FTV) Replacement

312

Fuel Injector Assy Components

314

Fuel Injector Assy Replacement

316

Fuel Injector Assy (1AZ–FSE) Components

319

Fuel Injector Assy (1ZZ–FE/3ZZ–FE) Components

324

Fuel Injector Assy (1ZZ–FE/3ZZ–FE) Replacement

325

Fuel Pressure Pulsation Damper Assy Replacement

329

Fuel Pump Assy Components

330

Fuel Pump Assy Replacement

333

Fuel Pump Assy (Gasoline) Components

337

Fuel Pump Assy (Gasoline) Replacement

338

Fuel Pump Assy (Gasoline) Inspection

342

Fuel System On-Vehicle Inspection

344

Check Fuel Pressure

344

Check Fuel Pump Operation and Fuel Tank

345

Fuel System (1AZ–FE) Precaution

347

Fuel System (1CD–FTV) Inspection

351

Fuel System (1ZZ–FE/3ZZ–FE) Inspection

353

Fuel System (1ZZ–FE/3ZZ–FE) On-Vehicle Inspection

355

Fuel System (1ZZ–FE/3ZZ–FE) Precaution

358

Fuel System (1AZ–FSE) Inspection

362

Fuel System (1AZ–FSE) Precaution

366

Fuel Tank Assy (Diesel) Components

369

Fuel Tank Assy (Diesel) Removal, Installation, Disassembly

372

Fuel Tank Assy (Gasoline) Components

379

Fuel Tank Assy (Gasoline) Removal, Installation, Disassembly

383

Injection or Supply Pump Assy (1CD–FTV) Components

391

Injection or Supply Pump Assy (1CD–FTV) Replacement

394

Injector Assy (1CD–FTV) Components

401

Injector Assy (1CD–FTV) Replacement

403

Emission Control

409

EGR System (1CD–FTV) Inspection

409

EGR System (1CD–FTV) On-Vehicle Inspection

411

Emission Control System (1AZ–FE) Inspection

412

Inspect Charcoal Canister Assy

412

Inspect Ventilation Valve Sub-Assy

412

Inspect Fuel Tank Cap Assy

412

Inspect Vacuum Switching Valve Assy No.1

413

Inspect Air Fuel Ratio Sensor

413

Inspect Heated Oxygen Sensor

414

Emission Control System (1AZ–FE) On-Vehicle Inspection

415

Inspect Air-Fuel Ratio Compensation System

415

Inspect Fuel Cut off RPM

415

Inspect Evaporative Emission Control System

415

Emission Control System (1AZ–FSE)

417

Emission Control System (1AZ–FSE) On-Vehicle Inspection

420

Emission Control System (1CD–FTV) On-Vehicle Inspection

422

Emission Control System (1ZZ–FE/3ZZ–FE) Inspection

423

Intake Air Control System (1AZ–FSE) Inspection

428

Inspect Intake Air Control Valve Assy

428

Intercooler Assy (1CD–FTV) Replacement

430

Turbo Charger System (1CD–FTV) Inspection

432

Turbo Charger System (1CD–FTV) Precaution

435

Turbocharger Sub-Assy (1CD–FTV) Components

437

Turbocharger Sub-Assy (1CD–FTV) Replacement

440

Camshaft (1AZ–FE) Components

447

Camshaft (1AZ–FE) Replacement

450

Camshaft (1AZ–FSE) Components

457

Camshaft (1AZ–FSE) Replacement

460

Camshaft (1CD–FTV) Components

466

Camshaft (1CD–FTV) Replacement

470

Camshaft (1ZZ–FE/3ZZ–FE) Components

478

Camshaft (1ZZ–FE/3ZZ–FE) Replacement

482

Chain Sub-Assy (1AZ–FE) Components

494

Chain Sub-Assy (1AZ–FE) Replacement

498

Chain Sub-Assy (1AZ–FSE) Components

526

Chain Sub-Assy (1ZZ–FE/3ZZ–FE) Components

530

Crankshaft Seal (1CD–FTV) Replacement

534

Cylinder Head Gasket (1AZ–FE) Components

537

Cylinder Head Gasket (1AZ–FE) Replacement

544

Cylinder Head Gasket (1AZ–FSE) Replacement

552

Cylinder Head Gasket (1CD–FTV) Components

561

Cylinder Head Gasket (1CD–FTV) Replacement

567

Cylinder Head Gasket (1ZZ–FE/3ZZ–FE) Components

577

Cylinder Head Gasket (1ZZ–FE/3ZZ–FE) Replacement

582

Drive Belt (1CD–FTV) Replacement

597

Engine (1AZ–FE) Inspection

598

Engine (1AZ–FSE) Inspection

602

Engine (1CD–FTV) Inspection

606

Engine (1ZZ–FE/3ZZ–FE) Inspection

609

Engine Rear Oil Seal (1AZ–FE) Replacement

613

Engine Rear Oil Seal (1AZ–FSE) Replacement

614

Engine Rear Oil Seal (1CD–FTV) Replacement

615

Engine Rear Oil Seal (1ZZ–FE/3ZZ–FE) Replacement

617

Fan and Generator V Belt (1AZ–FE) Replacement

620

Fan and Generator V Belt (1AZ–FSE) Replacement

621

Fan and Generator V Belt (1ZZ–FE/3ZZ–FE) Replacement

622

Partial Engine Assy (1AZ–FE) Components

623

Partial Engine Assy (1AZ–FE) Replacement

633

Partial Engine Assy (1CD–FTV) Components

647

Partial Engine Assy (1CD–FTV) Replacement

656

Partial Engine Assy (1ZZ–FE/3ZZ–FE) Components

675

Partial Engine Assy (1ZZ–FE/3ZZ–FE) Replacement

683

Timing Belt (1CD–FTV) Components

701

Timing Belt (1CD–FTV) Replacement

703

Timing Gear Cover Oil Seal (1ZZ–FE/3ZZ–FE) Replacement

710

Timing Gear Case or Timing Chain Case Oil Seal (1AZ–FE) Replacement

712

Timing Gear Case or Timing Chain Case Oil Seal (1AZ–FSE) Replacement

714

Valve Clearance (1AZ–FE) Adjustment

716

Valve Lifter Selection Chart (Intake)

718

Valve Lifter Selection Chart (Exhaust)

719

Valve Clearance (1ZZ–FE/3ZZ–FE) Adjustment

721

1ZZ-FE, 3ZZ-FE: Valve Lifter Selection Chart (Intake)

727

1ZZ-FE, 3ZZ-FE: Valve Lifter Selection Chart (Exhaust)

728

Exhaust Pipe Assy (1AZ–FE/1AZ–FSE) Components

734

Exhaust Pipe Assy (1AZ–FE/1AZ–FSE) Removal, Disassembly

735

Exhaust Pipe Assy (1CD–FTV) Components

737

Exhaust Pipe Assy (1CD–FTV) Removal, Installation, Disassembly

738

Exhaust Assy (1ZZ–FE/3ZZ–FE) Components

741

Exhaust Assy (1ZZ–FE/3ZZ–FE) Removal, Installation, Disassembly

742

Water Pump Assy (1ZZ–FE/3ZZ–FE) Inspection

746

Cylinder Block (1ZZ–FE/3ZZ–FE) Components

747

Cylinder Block (1ZZ–FE/3ZZ–FE) Overhaul

748

Cylinder Head Assy (1ZZ–FE/3ZZ–FE) Components

763

Cylinder Head Assy (1ZZ–FE/3ZZ–FE) Overhaul

764

Partial Engine Assy (1ZZ–FE/3ZZ–FE) Overhaul

777

Terms (1ZZ–FE/3ZZ–FE)

800

How to Use this Manual (1ZZ–FE/3ZZ–FE)

805

Repair Instruction (1NZ–FE/2NZ–FE)

811

Oil Pump Assy (1ZZ–FE/3ZZ–FE) Components

814

Oil Pump Assy (1ZZ–FE/3ZZ–FE) Overhaul

815

Generator Assy (1ZZ–FE/3ZZ–FE) Components

840

Generator Assy (1ZZ–FE/3ZZ–FE) Overhaul

841

Starter Assy (1ZZ–FE/3ZZ–FE) Components

847

Starter Assy (1ZZ–FE/3ZZ–FE) Overhaul

848

Cooling Fan System (1AZ–FE) On-Vehicle Inspection

855

Cooling Fan System (1AZ–FE) Inspection

856

Cooling Fan System (1AZ–FSE) On-Vehicle Inspection

857

Cooling Fan System (1AZ–FSE) Inspection

858

Cooling Fan System (1CD–FTV) On-Vehicle Inspection

859

Cooling Fan System (1CD–FTV) Inspection

860

Cooling Fan System (1ZZ–FE/3ZZ–FE) On-Vehicle Inspection

862

Cooling Fan System (1ZZ–FE/3ZZ–FE) Inspection

863

Radiator Assy (1ZZ–FE/3ZZ–FE) Replacement

864

Cooling System (1AZ–FE) On-Vehicle Inspection

866

Cooling System (1AZ–FE) Inspection

868

Cooling System (1AZ–FSE) On-Vehicle Inspection

870

Cooling System (1AZ–FSE) Inspection

872

Cooling System (1CD–FTV) On-Vehicle Inspection

874

Cooling System (1CD–FTV) Inspection

876

Cooling System (1ZZ–FE/3ZZ–FE) On-Vehicle Inspection

878

Cooling System (1ZZ–FE/3ZZ–FE) Inspection

880

Engine Coolant (1AZ–FE) Replacement

882

Engine Coolant (1AZ–FSE) Replacement

884

Engine Coolant (1CD–FTV) Replacement

886

Engine Coolant (1ZZ–FE/3ZZ–FE) Replacement

888

Radiator Assy (1AZ–FE) Replacement

890

Radiator Assy (1AZ–FSE) Replacement

891

Radiator Assy (1CD–FTV)

892

Thermostat (1AZ–FSE) Replacement

895

Thermostat (1CD–FTV) Replacement

896

Thermostat (1ZZ–FE/3ZZ–FE) Replacement

897

Thermostat (1AZ–FE) Replacement

898

Water Pump Assy (1AZ–FE) Replacement

899

Water Pump Assy (1AZ–FSE) Replacement

901

Water Pump Assy (1CD–FTV) Replacement

903

Water Pump Assy (1ZZ–FE/3ZZ–FE) Replacement

907

Lubrication System (1AZ–FE) On-Vehicle Inspection

908

Lubrication System (1AZ–FSE) On-Vehicle Inspection

910

Lubrication System (1CD–FTV) On-Vehicle Inspection

912

Lubrication System (1ZZ–FE/3ZZ–FE) On-Vehicle Inspection

914

Oil Cooler Assy (1CD–FTV) Replacement

916

Oil Filter Sub-Assy (1AZ–FE) Replacement

917

Oil Filter Sub-Assy (1AZ–FSE) Replacement

918

Oil Filter Sub-Assy (1CD–FTV) Replacement

919

Oil Filter Sub-Assy (1ZZ–FE/3ZZ–FE) Replacement

921

Oil Pump Assy (1AZ–FE) Replacement

923

Oil Pump Assy (1AZ–FSE) Replacement

927

Oil Pump Assy (1CD–FTV) Replacement

931

Oil Pump Assy (1ZZ–FE/3ZZ–FE) Replacement

939

Camshaft Position Sensor (1AZ–FE/1AZ–FSE) Replacement

940

Camshaft Position Sensor (1ZZ–FE/3ZZ–FE) Replacement

941

Crankshaft Position Sensor (1AZ–FE/1AZ–FSE) Replacement

942

Crankshaft Position Sensor (1ZZ–FE/3ZZ–FE) Replacement

943

Ignition System (1AZ–FE) On-Vehicle Inspection

944

Ignition System (1AZ–FE) Inspection

946

Ignition System (1AZ–FSE) On-Vehicle Inspection

949

Ignition System (1AZ–FSE) Inspection

951

Inspect Spark Plug

951

Ignition System (1ZZ–FE/3ZZ–FE) On-Vehicle Inspection

953

Ignition System (1ZZ–FE/3ZZ–FE) Inspection

955

Charging System (1AZ–FE) Precautions

957

Charging System (1AZ–FE) On-Vehicle Inspection

958

Check Battery Electrolyte Level

958

Check Battery Voltage

958

Inspect Drive Belt

958

Inspect Charging Circuit

959

Charging System (1AZ–FSE) Precaution

960

Charging System (1AZ–FSE) On-Vehicle Inspection

961

Charging System (1CD–FTV) Precaution

963

Charging System (1CD–FTV) On-Vehicle Inspection

964

Charging System (1ZZ–FE/3ZZ–FE) Precaution

967

Charging System (1ZZ–FE/3ZZ–FE) On-Vehicle Inspection

968

Generator Assy Replacement

970

Glow Plug Assy Replacement

974

Pre-Heating System On-Vehicle Inspection

975

Pre-Heating System Inspection

977

Starter Assy Replacement

978

Starting System Inspection

982

Front Shock Absorber with Coil Spring Overhaul

990

Dispose of Shock Absorber Assy Front LH

995

Front Suspension Components

996

Front Suspension Arm Sub-Assy Lower No.1 LH Replacement

1000

Front Suspension System Problem Symptoms Table

1008

Front Wheel Adjustment

1009

Measure Vehicle Height

1009

Inspect Toe-In

1009

Adjust Toe-In

1009

Inspect Wheel Angle

1010

Inspect Camber, Caster and Steering Axis Inclination

1010

Adjust Camber

1011

Lower Ball Joint Assy Front LH Replacement

1013

Stabilizer Bar Front Replacement

1015

Lower Control Arm Assy LH Replacement

1018

Rear Shock Absorber with Coil Spring Ovehaul

1021

Dispose of Shock Absorber Assy Rear LH

1027

Rear Suspension Components

1028

Rear Suspension Arm Assy No. 1 LH Overhaul

1030

Rear Suspension System Problem Symptoms Table

1039

Rear Wheel Adjustment

1040

Stabilizer Bar Rear Replacement

1044

Upper Control Arm Assy Replacement

1046

Wheel and Tire System Inspection

1048

Drive Shaft, Propeller Shaft, Axle Problem Symptoms Table

1050

Drive Shaft, Propeller Shaft, Axle On-Vehicle Inspection

1051

Front Axle Hub Sub-Assy LH Components

1052

Front Axle Hub Sub-Assy LH Replacement

1053

Front Axle LH Hub Bolt Replacement

1060

Front Drive Shaft Components

1061

Rear Axle Carrier Sub-Assy LH Components

1064

Rear Axle Carrier Sub-Assy LH Replacement

1065

Rear Axle LH Hub Bolt Replacement

1070

Brake Actuator Assy (W/ VSC) On-Vehicle Inspection

1071

Brake Actuator Assy Replacement

1073

Brake Booster Assy On-Vehicle Inspection

1075

Brake Booster Assy Components

1076

Brake Booster Assy Replacement

1077

Brake Fluid Bleeding

1091

Brake Master Cylinder Sub-Assy Components

1093

Brake Master Cylinder Sub-Assy Replacement

1095

Brake Pedal Sub-Assy Adjustment

1099

Brake Pedal Sub-Assy Components

1101

Brake Pedal Sub-Assy Replacement

1102

Brake System Precaution

1104

Brake System Problem Symptoms Table

1105

Front Brake Components

1107

Front Brake Overhaul

1108

Rear Disc Brake Components

1113

Rear Disc Brake Overhaul

1114

Skid Control Sensor Replacement

1120

Speed Sensor Front LH Replacement

1122

Steering Sensor Replacement

1124

Vacuum Pump Assy On-Vehicle Inspection

1127

Vacuum Pump Assy Components

1128

Vacuum Pump Assy Overhaul

1129

Yawrate Sensor Replacement

1134

Parking Brake Assy Components

1138

Parking Brake Assy Overhaul

1139

Parking Brake Cable Assy No.1 Components

1145

Parking Brake Cable Assy No.1 Replacement

1146

Parking Brake Cable Assy No.3 Components

1148

Parking Brake Cable Assy No.3 Replacement

1149

Parking Brake Lever Sub-Assy Components

1152

Parking Brake Lever Sub-Assy Replacement

1153

Parking Brake System Problem Symptoms Table

1155

Parking Brake System Adjustments

1156

Floor Shift Shift Lever Assy Components

1157

Floor Shift Shift Lever Assy Replacement

1158

Front Differential Oil Seal Replacement

1160

Manual Transaxle Assy Components

1164

Manual Transaxle Assy Replacement

1166

Manual Transaxle Oil On-Vehicle Inspection

1185

Manual Transaxle System Problem Symptoms Table

1186

Transmission Control Cable Assy Replacement

1187

Clutch Accumulator Assy Components

1190

Clutch Accumulator Assy Replacement

1191

Clutch Master Cylinder Assy Components

1192

Clutch Master Cylinder Assy Replacement

1193

Clutch Pedal Sub-Assy Adjustment

1196

Clutch Pedal Sub-Assy Components

1198

Clutch Pedal Sub-Assy Replacement

1200

Clutch Release Cylinder Assy Components

1206

Clutch Release Cylinder Assy Overhaul

1207

Clutch System Problem Symptoms Table

1211

Clutch Unit Componets

1212

Clutch Unit Overhaul

1215

Steering Column

1219

Power Steering ECU Assy Replacement

1219

Steering Column Assy Components

1222

Electric Power Steering Diagram

1224

Steering Column Assy Overhaul

1226

Steering System Precaution

1237

Steering System Problem Symptoms Table

1238

Electric Power Steering

1239

Steering System On-Vehicle Inspection

1240

Power Steering System Precaution

1241

Power Steering System Problem Symptoms Table

1242

Power Steering System On-Vehicle Inspection

1244

Rack and Pinion Power Steering Gear Assy Components

1248

Rack and Pinion Power Steering Gear Assy Overhaul

1250

Steering Gear Assy Components

1260

Steering Gear Assy Overhaul

1261

Vane Pump Assy Components

1267

Vane Pump Assy Overhaul

1268

Vane Pump Assy (AZ Series) Components

1276

Vane Pump Assy (AZ Series) Overhaul

1277

Air Conditioning Control Assy Components

1286

Air Conditioning Control Assy Overhaul

1288

Air Conditioning Radiator Assy Components

1291

Air Conditioning System Precaution

1293

Air Conditioning System On-Vehicle Inspection

1295

Air Conditioning System Problem Symptoms Table

1298

Air Conditioning System Problem Inspection

1299

Blower Assy Components

1305

Blower Assy Overhaul

1306

Combustion Type Power Heater System On-Vehicle Inspection

1310

Combustion Type Power Heater System Diagnostic Trouble Code Chart

1312

Combustion Type Power Heater System Inspection

1314

Inspect Heater Assy

1314

Inspect Heater Switch Assy

1315

Combustion Type Power Heater System Problem Symptoms Table

1317

Heater Assy Replacement

1321

Hot Gas Type Power Heater System On-Vehicle Inspection

1323

Hot Gas Type Power Heater System Inspection

1324

Refrigerant On-Vehicle Inspection

1325

Inspect Refrigerant Volume

1332

Inspect Refrigerant Pressure with Manifold Gauge Set

1333

Refrigerant Replacement

1339

Refrigerant Line Components

1340

V (Cooler Compressor to Crankshaft Pulley) Belt No.1 Replacement

1347

W/Pulley Compressor Assy On-Vehicle Inspection

1349

W/Pulley Compressor Assy Replacement

1350

W/Receiver Condenser Assy On-Vehicle Inspection

1370

W/Receiver Condenser Assy Components

1371

W/Receiver Condenser Assy Overhaul

1373

Supplemental Restraint System

1390

Air Bag Sensor Assy Center Components

1390

Air Bag Sensor Assy Center Replacement

1391

Air Bag Sensor Front LH Components

1392

Air Bag Sensor Front LH Replacement

1393

Air Bag Sensor Rear LH Components

1394

Air Bag Sensor Rear LH Replacement

1395

Curtain Shield Air Bag Assy LH Components

1396

Curtain Shield Air Bag Assy LH Replacement

1398

Curtain Shield Air Bag Assy LH Disposal

1401

Front Seat Airbag Assy LH Disposal

1407

Steering Wheel Assy Components

1413

Steering Wheel Assy Replacement

1414

Horn Button Assy Disposal

1416

Instrument Panel Air Bag Assy Components

1423

Instrument Panel Air Bag Assy Replacement

1424

Instrument Panel Air Bag Assy Disposal

1425

Instrument Panel Passenger Air Bag Assy Components

1431

Instrument Panel Passenger Air Bag Assy Replacement

1432

Instrument Panel Passenger Air Bag Assy Disposal

1433

Seat Position Air Bag Sensor Components

1439

Seat Position Air Bag Sensor Replacement

1440

Side Air Bag Sensor Assy LH Components

1441

Side Air Bag Sensor Assy LH Replacement

1442

Spiral Cable Sub-Assy Replacement

1443

Supplemental Restraint System Precaution

1445

Audio System

1446

SRS Connectors

1447

Supplemental Restraint System On-Vehicle Inspection

1455

Seat Belts

1460

Front Seat Belt Precautions

1460

Front Seat Belt Components

1461

Front Seat Belt Replacement

1462

Front Seat Belt Disposal

1464

Rear Seat Belt (Liftback Models) Components

1469

Rear Seat Belt (Liftback Models) Replacement

1470

Rear Seat Belt (Sedan Models) Components

1473

Rear Seat Belt (Sedan Models) Replacement

1474

Rear Seat Belt (Wagon Models) Components

1478

Rear Seat Belt (Wagon Models) Replacement

1479

Seat Belt Warning System Location

1482

Seat Belt Warning System Symptoms Table

1483

Seat Belt Warning System Inspection

1484

Center Stop Lamp Assy Replacement

1486

Fog Lamp Assy LH Replacement

1487

Fog Lamp Assy LH Adjustment

1488

Headlamp Dimmer Switch Assy Replacement

1489

Headlamp Leveling ECU Assy Replacement

1490

Headlamp Unit LH Components

1491

Headlamp Unit LH Replacement

1492

Headlamp Unit LH Adjustment

1495

Height Control Sensor Sub-Assy FR RH Replacement

1497

Height Control Sensor Sub-Assy Rear RH Replacement

1498

License Plate Lamp Assy Replacement

1499

Lighting System Precaution

1500

Headlight System Problem Symptoms Table

1501

Illuminated Entry System

1502

Lighting System On-Vehicle Inspection

1504

Headlamp Auto Levering Operation Check

1506

Headlamp Dimmer Switch Assy Inspection

1508

Hazard Warning Signal Switch Assy Inspection

1508

Front Door Courtesy Lamp Switch Assy Check

1509

Rear Door Courtesy Lamp Switch Assy Check

1509

Back Door Lock Assy Check

1509

Relays Check

1510

Transponder Key Amplifier Check

1510

Map Lamp Assy Check

1511

Room Lamp Assy No.2 Check

1511

Glove Box Lamp Assy Check

1511

LH Visor Assy Check

1511

Headlamp Leveling Switch Check

1512

Stop Lamp Switch Assy (W/O Cruise Control) Check

1512

Back up Lamp Switch Assy Check

1512

Height Control Sensor Sub-Assy FR RH Check

1513

Height Control Sensor Sub-Assy Rear RH Check

1513

Rear Combination Lamp Assy LH Replacement

1514

Side Turn Signal Lamp Assy LH Replacement

1515

Headlamp Washer Actuator Sub-Assy LH Replacement

1516

Rain Sensor Replacement

1517

Rear Wiper Motor Assy Replacement

1519

Rear Wiper Rubber Replacement

1521

Washer Nozzle Sub-Assy Adjustment

1523

Windshield Wiper Motor Assy Replacement

1525

Windshield Wiper Switch Assy Replacement

1529

Wiper and Washer System Precaution

1530

Wiper and Washer System Problem Symptoms Table

1531

Wiper and Washer System On-Vehicle Inspection

1533

Wiper and Washer System Inspection

1535

Wiper Rubber LH Replacement

1542

Amplifier Antenna Assy Replacement

1543

Navigation System

1544

Antenna Cord Sub-Assy Replacement

1550

Antenna Cord Sub-Assy No.3 Replacement

1551

Audio and Visual System Precaution

1554

Audio and Visual System Components

1555

Cigarette Lighter Assy Replacement

1558

Front No.1 Speaker Assy Replacement

1561

Front No.2 Speaker Assy Replacement

1563

Multi-Display (CRT Display) Replacement

1564

Navigation Antenna Assy Replacement

1568

Navigation ECU Replacement

1569

Power Point Socket Assy Replacement

1570

Radio Receiver Assy Replacement

1571

Rear Speaker Assy Replacement

1572

Rear Speaker Assy No.2 Replacement

1574

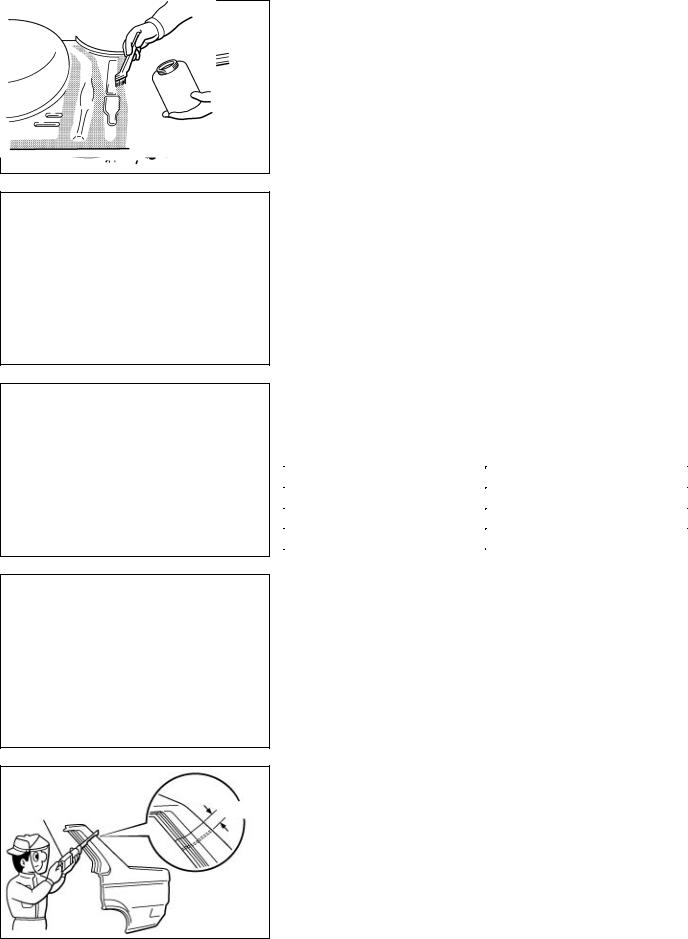

Window Glass (Antenna Wire) Repair

1575

Power Source Location

1576

High Pitched Horn Assy Replacement

1583

Horn System Location

1584

Horn System Problem Symptoms Table

1585

Horn System Inspection

1586

Low Pitched Horn Assy Replacement

1587

Back Door Glass Components

1588

Back Door Glass Replacement

1589

Inner Rear View Mirror Assy Replacement

1607

Outer Rear View Mirror Assy LH Replacement

1608

Power Mirror Control System On-Vehicle Inspection

1609

Power Mirror Control System Location

1611

Power Mirror Control System Problem Symptoms Table

1612

Power Mirror Control System Inspection

1613

Power Mirror Control System Reset

1630

Quarter Window Assy LH Components

1631

Quarter Window Assy LH Replacement

1632

Window Defogger System Location

1636

Window Defogger System Problem Symptom Table

1639

Window Defogger System Inspection

1640

Windshield Glass Components

1645

Windshield Glass Replacement

1646

Combination Meter Problem Symptoms Table

1653

Combination Meter On-Vehicle Inspection

1655

Inspect Speedometer

1655

Inspect Output Signal of Vehicle Speed

1655

Inspect Tachometer

1656

Inspect Fuel Receiver Gauge

1656

Inspect Fuel Level Warning

1656

Inspect Coolant Temperature Receiver Gauge Warning Light

1656

Inspect Seat Belt Warning Light and Buzzer

1657

Inspect Low Oil Pressure Warning Light

1657

Inspect Brake Warning Light

1657

Inspect Brake Fluid Level Warning Switch

1657

Inspect Key Reminder Warning Buzzer

1658

Combination Meter Assy Overhaul

1659

Instrument Panel/Meter Components

1660

Instrument Panel Sub-Assy Lower Precaution

1663

Multi-Display (CRT Display) Display Replacement

1664

Front Power Seat Control System Location

1665

Front Power Seat Control System Problem Symptoms Table

1667

Front Power Seat Control System On-Vehicle Inspection

1668

Front Power Seat Control System Inspection

1670

Driver Side

1670

Front Seat Assembly LH (Manual Seat Type) Components

1674

Front Seat Assembly LH (Manual Seat Type) Overhaul

1675

Front Seat Assembly (Power Seat Type) Components

1678

Front Seat Assembly (Power Seat Type) Overhaul

1679

Rear Seat Assy (40/60 Folding Flip-Up Cushion) Components

1683

Rear Seat Assy (40/60 Folding Flip-Up Cushion) Overhaul

1685

Rear Seat Assy (40/60 Folding) Components

1689

Rear Seat Assy (40/60 Folding) Overhaul

1691

Rear Seat Assy (United Fixed) Components

1695

Rear Seat Assy (United Fixed) Overhaul

1696

Seat Heater System Location

1698

Seat Heater System Problem Symptoms Table

1700

Seat Heater System Inspection

1701

Fuel Lid Opener System Location

1704

Fuel Lid Opener System Problem Symptoms Table

1706

Fuel Lid Opener System Inspection

1707

Key Reminder Warning System On-Vehicle Inspection

1708

Power Door Lock Control System On-Vehicle Inspection

1709

Power Door Lock Control System Inspection

1711

Theft Deterrent System On-Vehicle Inspection

1722

Active Arming Mode

1723

Forced Door Lock Control

1725

Alarm Memory Function

1725

Security Indicator Output

1725

Intrusion (Theft Warning) Sensor

1726

Theft Warning (Self-Power) Siren

1726

Transmitter Battery Replacement

1727

Transmitter Sub-Assy Module Set Door Control Replacement

1728

Transmitter Sub-Assy Module Set Door Control Inspection

1729

Register Recognition Code

1731

Flow Chart of Recognition Code Registration

1732

Wireless Door Lock Control System Precaution

1736

Wireless Door Lock Control System On-Vehicle Inspection

1737

Sliding Roof Components

1739

Sliding Roof Replacement

1746

Sliding Roof System Location

1747

Sliding Roof System On-Vehicle Inspection

1749

Sliding Roof System Problem Symptoms Table

1751

Sliding Roof System Problem Inspection

1752

Reset Sliding Roof Motor

1753

Back Door Components

1754

Back Door Adjustment

1755

Back Door Overhaul

1757

Back Door Stay Replacement

1764

Back Door Stay Disposal

1765

Front Door Components

1766

Front Door Adjustment

1768

Front Door Overhaul

1770

Hood Components

1780

Hood Adjustment

1781

Luggage Compartment Door Components

1783

Luggage Compartment Door Adjustment

1784

Luggage Door Hinge Torsion Bar Replacement

1786

Backdoor Garnish Sub-Assy Outside Replacement

1788

Front Bumper Components

1790

Front Bumper Replacement

1792

Front Floor Footrest Replacement

1794

Fuel Lid Lock Control Assy Components

1796

Fuel Lid Lock Control Assy Replacement

1799

Luggage Compartment Door Garnish Sub-Assy Outside Replacement

1802

Name Plate Replacement

1803

Outside Moulding LH Replacement

1807

Rear Bumper Components

1809

Rear Bumper Replacement

1810

Rear Door Belt Moulding Assy LH Replacement

1815

Rear Spoiler Replacement

1816

Rocker Panel Moulding LH Replacement

1818

Roof Drip Side Finish Moulding Center LH Replacement

1819

Roof Handling Assy Components

1820

Roof Handling Assy Replacement

1823

Ignition or Starter Switch Assy Replacement

1848

Ignition or Starter Switch Assy Inspection

1849

Manual B — How to Use

1851

Troubleshooting

1860

Voltage Check

1860

Continuity and Resistance Check

1860

Finding a Short Circuit

1861

Disconnection of Male and Female Connectors

1861

How to Replace Terminal

1862

Abbreviations

1865

Glossary of Terms and Symbols

1866

Relay Locations

1868

Engine Compartment

1868

Electrical Wiring Routing

1880

Power Source

1906

Starting

1909

Charging

1910

Ignition

1912

Engine Control

1913

Engine Immobiliser System

1926

Engine Immobiliser System Electrical Diagram

1944

Multiplex Communication System (Communication Bus) Electrical Diagram

1945

Multiplex Communication System (RHD) Electrical Diagram

1946

Headlight (W/ Daytime Running Light) Electrical Diagram

1957

Headlight (W/O Daytime Running Light) Electrical Diagram

1961

Front Fog Light Electrical Diagram

1963

Rear Fog Light Electrical Diagram

1964

Taillight Electrical Diagram

1965

Turn Signal and Hazard Warning Light

1967

Stop Light Electrical Diagram

1969

Back–Up Light Electrical Diagram

1970

Illumination Electrical Diagram

1971

Interior Light (RHD) Electrical Diagram

1976

Headlight Beam Level Control (W/ HID) Electrical Diagram

1980

Headlight Beam Level Control (W/O HID) Electrical Diagram

1982

Headlight Cleaner (W/ HID) Electrical Diagram

1984

Headlight Cleaner (W/O HID) Electrical Diagram

1985

Key Reminder and Light Reminder Electrical Diagram

1986

Seat Belt Warning Electrical Diagram

1988

ECT and A/T Indicator Electrical Diagram

1990

Cruise Control Electrical Diagram

2004

VSC Electrical Diagram

2012

ABS Electrical Diagram

2018

SRS Electrical Diagram

2022

EPS Electrical Diagram

2026

Door Lock Control (RHD) and Theft Deterrent Electrical Diagram

2028

Wireless Door Lock Control (RHD) Electrical Diagram

2037

Double Locking Electrical Diagram

2041

Power Window (RHD) Electrical Diagram

2046

Front Wiper and Washer (W/ Auto Wiper System) Electrical Diagram

2050

Front Wiper and Washer (W/O Auto Wiper System) Electrical Diagram

2052

Rear Wiper and Washer Electrical Diagram

2054

Moon Roof Electrical Diagram

2055

Shift Lock Electrical Diagram

2057

Horn Electrical Diagram

2058

Fuel Lid Opener Electrical Diagram

2059

Fuel Heater Electrical Diagram

2060

Automatic Glare – Resistant EC Mirror Electrical Diagram

2061

Cigarette Lighter Electrical Diagram

2062

Power Outlet Electrical Diagram

2063

Front Window Deicer Electrical Diagram

2064

Rear Window Defogger Electrical Diagram

2065

Mirror Heater Electrical Diagram

2067

Remote Control Mirror Electrical Diagram

2068

Power Seat Electrical Diagram

2069

Seat Heater Electrical Diagram

2071

Navigation System (Map Type) Electrical Diagram

2073

Multi–Display (W/O Navigation System Map Type) Electrical Diagram

2077

Radio and Player Electrical Diagram

2079

Combination Meter

2081

Radiator Fan and Condenser Fan Electrical Diagram

2087

Air Conditioner (Automatic A/C) Electrical Diagram

2090

Power Heater (Hot Gas Type Automatic A/C) Electrical Diagram

2091

Power Heater (Hot Gas Type Manual A/C) Electrical Diagram

2097

Heater Electrical Diagram

2098

Power Heater (Electrical Type) Electrical Diagram

2101

Power Heater (Combustion Type) Electrical Diagram

2103

Ground Point

2104

Power Source (Current Flow Chart)

2111

Driver Side J/B

2113

Engine Room R/B No.1 (1CD–FTV)

2116

Engine Room R/B No.1 (Gasoline)

2117

Engine Room R/B No.2

2118

Engine Room R/B No.3

2118

Engine Room R/B No.4

2119

Fuse Block

2120

Connector List

2123

Part Number of Connectors

2137

Overall Electrical Wiring Diagram

2143

Toyota Avensis T250 с бензиновыми двигателями: 3ZZ-FE 1.6 л (1598 см³) 108 л.с./79,4 кВт, 1ZZ-FE 1.8 л (1794 см³) 129 л.с./95 кВт, 1AZ-FE LG 2.0 л (1998 см³) 135 л.с./99 кВт, 1AZ-FSE 2.0 л D-4 (1998 см³) 147 л.с./108 кВт, 2AZ-FSE 2.4 л D-4 (2362 см³) 163 л.с./120 кВт; Руководство по эксплуатации, техническому обслуживанию и ремонту, технические характеристики, электросхемы, контрольные размеры кузова, устройство, диагностика. Тойота Авенсис модели второго поколения с кузовами пятидверный хэтчбек/liftback, универсал/estate и седан/saloon выпуска с 2003 по 2009 год

ЕСЛИ ВЫ ВИДИТЕ ОШИБКУ 406 Not Acceptable и не видите документ, то скорей всего у Вас IP РФ и его надо сменить, на любой другой страны, с помощью VPN ( Scribd и SlideShare блокируют посетителей с Российским IP).

Видео Toyota Avensis замена салонного фильтра и передних тормозных колодок, дисков/ how to replace disc brakes (Тойота Авенсис 03-09)

Toyota Avensis T250 Mark II общая информация (Тойота Авенсис 2003-2009)

В 2003 году компания Toyota Motor Corporation выпустила второе поколение автомобиля среднего класса D Toyota Avensis. Автомобиль был спроектирован во французском дизайн-центре Toyota. В самом начале продаж автомобиль был представлен с тремя бензиновыми и одним дизельным моторами. Бензиновые двигатели объемом 1.6, 1.8 и 2.0 л развивали мощность 110, 129 и 147 л.с. соответственно и оснащались механизмом изменяемых фаз газораспределения VVТ-i.

В 2006 году был представлен обновленный Toyota Avensis. Автомобиль получил новую решетку радиатора, новые фары и задние фонари. Небольшие изменения произошли и в интерьере. Линейка моторов пополнилась бензиновым двигателем объемом 2,4 л, мощностью 163 л.с. На автомобили устанавливали 5-ступенчатые механические и 4-ступенчатые автоматические коробки передач. Автомобили Toyota Avensis выпускались с кузовами седан, хэтчбек и универсал.

Автомобиль поставлялся на российский рынок с четырехцилиндровыми рядными 16-клапанными бензиновыми двигателями объемом 1,8 л (129 л.с.), 2,0 л (147 л.с.) и 2,4 л (163 л.с.) с механизмом изменяемых фаз газораспределения VVT-i и предлагался в трех комплектациях с кузовом седан и универсал:

— Terra (только двигатель 1,8 л, МКП, кузов седан, ABS+EBD, система курсовой устойчивости (VSC), система автоматического противопробуксовывания колес (TRC), система помощи при экстренном торможении (ВА), кондиционер, электроусилитель руля, рулевая колонка с регулировкой по высоте и вылету, 6 подушек безопасности, система подсветки приборов Optitron, боковые зеркала заднего вида со встроенными указателями поворотов и электроприводом, радио/ СD-аудиосистема с 8 динамиками и возможностью воспроизведения файлов в формате МР3 и WMA, стальные диски колес 205/55 R16, электростеклоподъемники на всех дверях, складывающиеся задние сиденья, иммобилизатор, система дистанционного управления замками дверей);

— Sol (двигатель 1,8 и 2,0 л с механической или автоматической коробкой переключения передач, кузов седан или универсал, дополнительно к оборудованию Terra — раздельный климат-контроль, 9 подушек безопасности, гидроусилитель (с двигателем 2,0 л) руля, круиз — контроль, мультиинформационный дисплей, обогрев передних сидений и боковых зеркал, электропривод складывания боковых зеркал, противотуманные фары, омыватели фар, датчик дождя, обтянутое кожей рулевое колесо, регулировка положения передних сидений по 6 направлениям);

— Lux (двигатель 2,0 и 2,4 л с автоматической коробкой передач, кузов — седан, дополнительно к оборудованию Sol — кожаный салон, ксеноновые фары, электрические регулировки передних сидений, CD-чейнджер на 6 дисков, электрическая шторка заднего окна, регулировка положения поясничного подпора на сиденье водителя). В комплектацию автомобилей Toyota Avensis для российского рынка входят: защита картера двигателя и порогов, брызговики всех колес и полноразмерное запасное колесо.

Кузова всех модификаций автомобилей Toyota Avensis несущие, цельнометаллические, сварной конструкции с навесными передними крыльями, дверьми, капотом и крышкой багажника. Ветровое и заднее стекла вклеенные. Сиденье водителя регулируется в продольном направлении, по наклону спинки и высоте, сиденье переднего пассажира — в продольном направлении и по наклону спинки. Передние и задние сиденья оборудованы регулируемыми по высоте подголовниками. Спинка заднего сиденья может быть сложена по частям в пропорции 40:60.

Трансмиссия выполнена по переднеприводной схеме с приводами колес, оснащенными шарнирами равных угловых скоростей. Передняя подвеска независимая, пружинная, на поперечных рычагах, со стабилизатором поперечной устойчивости, с гидравлическими амортизаторными стойками. Задняя подвеска независимая, многорычажная, с гидравлическими амортизаторными стойками и стабилизатором поперечной устойчивости. Тормозные механизмы передних колес дисковые, вентилируемые, с плавающей скобой, задних колес — дисковые, с плавающей скобой. Тормозная система оснащена вакуумным усилителем и системой помощи при экстренном торможении.

Рулевое управление травмобезопасное, с рулевым механизмом типа шестерня-рейка, с гидроусилителем или электроусилителем. Рулевая колонка регулируется по вылету и углу наклона. В ступице рулевого колеса расположена фронтальная подушка безопасности. Все автомобили оснащены инерционными диагональными ремнями безопасности для водителя, переднего пассажира и пассажиров на заднем сиденье. Для переднего пассажира предусмотрена фронтальная подушка безопасности.

| № | Спецификация / Specs | Данные |

| Габариты (мм/mm) и масса (кг/kg) / Dimensions and Weight | ||

| 1 | Длина / Length | 4645 |

| 2 | Ширина (без/с зеркалами) / Width | 1760 |

| 3 | Высота (загружен/пустой) / Height | 1480 |

| 4 | Колёсная база / Wheelbase | 2700 |

| 5 | Дорожный просвет (клиренс) / Ground clearance | 140 |

| 6 | Снаряжённая масса / Total (curb) weight | 1410 |

| Полная масса / Gross (max.) weight | 1900 | |

|

Двигатель / Engine |

||

| 7 | Тип / Engine Type, Code | Бензиновый, жидкостного охлаждения, четырехтактный, 2AZ-FSE D-4 |

| 8 | Количество цилиндров / Cylinder arrangement: Total number of cylinders, of valves | 4-цилиндровый, 16V, рядный, DOHC с верхним расположением двух распределительных валов, VVT-i |

| 9 | Диаметр цилиндра / Bore | 88.5 мм |

| 10 | Ход поршня / Stroke | 96.0 мм |

| 11 | Объём / Engine displacement | 2362 см³ |

| 12 | Система питания / Fuel supply, Aspiration | Распределенный впрыск топлива MPI — Toyota TCCS |

| Атмосферный | ||

| 13 | Степень сжатия / Compression ratio | 11.0:1 |

| 14 | Максимальная мощность / Max. output power kW (HP) at rpm | 120 кВт (163 л.с.) при 5800 об/мин |

| 15 | Максимальный крутящий момент / Max. torque N·m at rpm | 230 Нм при 3800 об/мин |

|

Трансмиссия / Transmission |

||

| 16 | Сцепление / Clutch type | Гидротрансформатор |

| 17 | КПП / Transmission type | U151E АКПП 5 Автоматическая, пятиступенчатая, гидромеханическая, адаптивная |

О Книге

- Название: Toyota Avensis T250 Руководство по эксплуатации, техническому обслуживанию и ремонту

- Бензиновые двигатели: 3ZZ-FE 1.6 л (1598 см³) 108 л.с./79,4 кВт, 1ZZ-FE 1.8 л (1794 см³) 129 л.с./95 кВт, 1AZ-FE LG 2.0 л (1998 см³) 135 л.с./99 кВт, 1AZ-FSE 2.0 л D-4 (1998 см³) 147 л.с./108 кВт, 2AZ-FSE 2.4 л D-4 (2362 см³) 163 л.с./120 кВт

- Выпуск с 2003 года

- Серия: «Ремонт Автомобилей»

- Год издания: 2007

- Автор: Коллектив авторов

- Издательство: «Ассоциация независимых издателей»

- Формат: PDF

- Страниц в книге: 519

- Размер: 162.51 МБ

- Язык: Русский

- Количество электросхем: 93

Сборник руководств на английском языке по техническому обслуживанию и ремонту автомобиля Toyota Avensis 1998-2002 годов выпуска.

- Автор: —

- Издательство: Toyota Motor Corporation

- Год издания: —

- Страниц: —

- Формат: PDF

- Размер: 651,2 Mb

Сборник руководств на английском языке по техническому обслуживанию и ремонту автомобиля Toyota Avensis 2003-2009 годов выпуска.

- Автор: —

- Издательство: Toyota Motor Corporation

- Год издания: —

- Страниц: —

- Формат: PDF, ISO

- Размер: 659,3 Mb

Руководство по техническому обслуживанию и ремонту автомобиля Toyota Avensis 1998-2003 годов выпуска.

- Автор: —

- Издательство: Алфамер

- Год издания: —

- Страниц: 336

- Формат: —

- Размер: —

Руководство по эксплуатации и техническому обслуживанию автомобиля Toyota Avensis 2005 года выпуска.

- Автор: —

- Издательство: Toyota Motor Corporation

- Год издания: 2004

- Страниц: 364

- Формат: PDF

- Размер: 66,4 Mb

Руководство по эксплуатации, техническому обслуживанию и ремонту + каталог расходных запчастей автомобиля Toyota Avensis 1997-2003 годов выпуска с бензиновыми двигателями объемом 1,6/1,8/2,0 л.

- Автор: —

- Издательство: Легион-Автодата

- Год издания: —

- Страниц: 456

- Формат: —

- Размер: —

Руководство по эксплуатации, техническому обслуживанию и ремонту + каталог расходных запчастей автомобиля Toyota Avensis 2003-2008 годов выпуска с бензиновыми двигателями объемом 1,6/1,8/2,0/2,4 л.

- Автор: —

- Издательство: Легион-Автодата

- Год издания: —

- Страниц: 456

- Формат: —

- Размер: —

Руководство по эксплуатации, техническому обслуживанию и ремонту автомобиля Toyota Avensis с 2003 года выпуска.

- Автор: —

- Издательство: Монолит

- Год издания: —

- Страниц: 268

- Формат: —

- Размер: —

Руководство по эксплуатации и ремонту автомобилей Toyota Avensis с 2003 года выпуска с бензиновыми и дизельными двигателями.

- Автор: —

- Издательство: Гуси-Лебеди

- Год издания: —

- Страниц: 404

- Формат: —

- Размер: —

Руководство по эксплуатации и ремонту автомобиля Toyota Avensis с 2009 года выпуска с бензиновыми и дизельными двигателями.

- Автор: —

- Издательство: Монолит

- Год издания: —

- Страниц: 428

- Формат: —

- Размер: —

Руководство по эксплуатации и техническому обслуживанию автомобиля Toyota Avensis с 2002 года выпуска.

- Автор: —

- Издательство: MoToR

- Год издания: —

- Страниц: 372

- Формат: —

- Размер: —

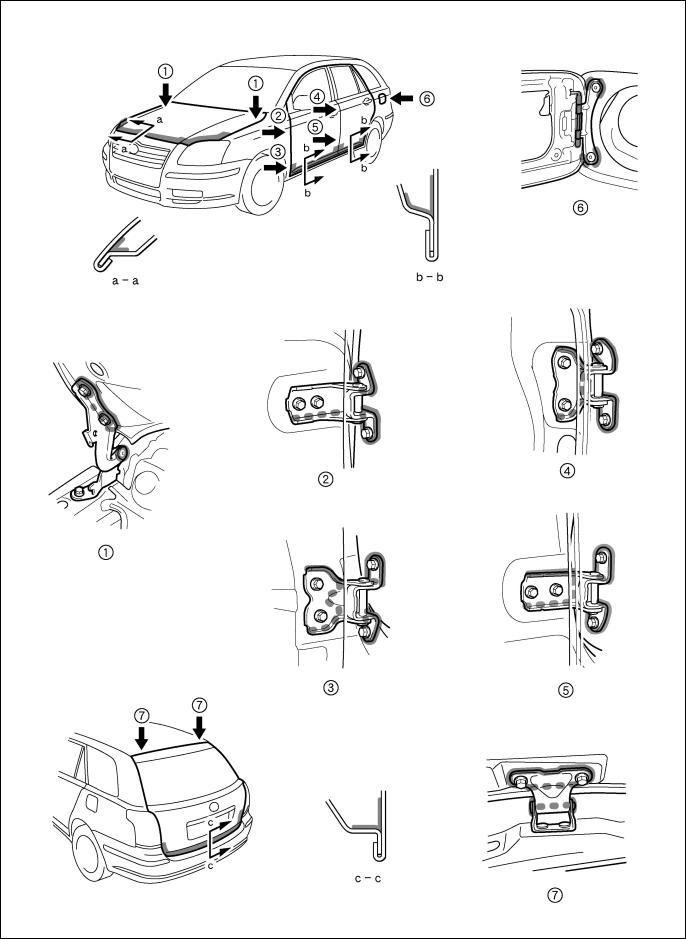

|

BODY PANEL REPLACEMENT |

BP-1 |

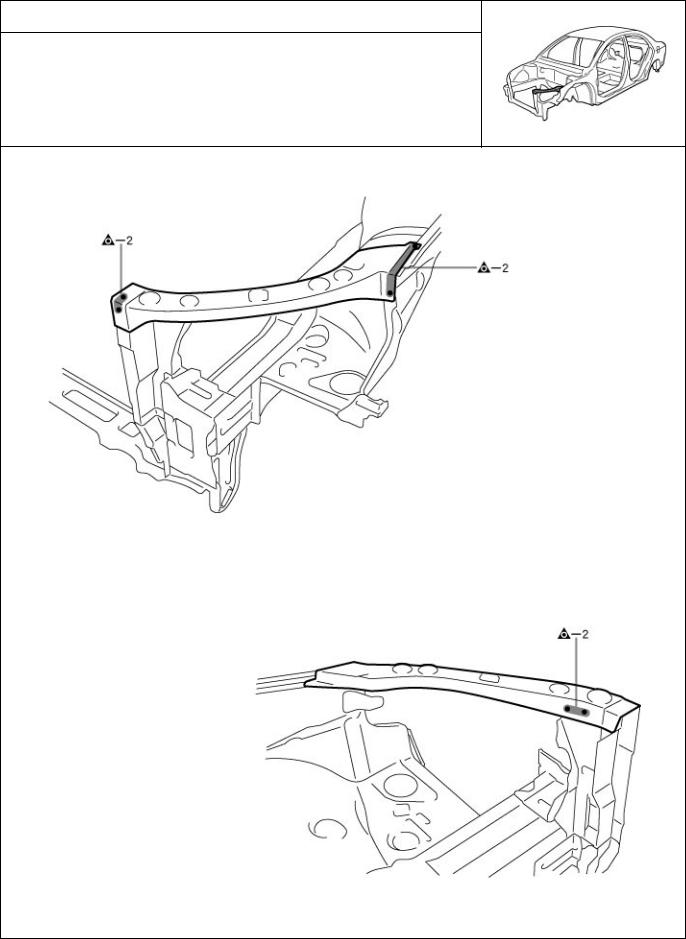

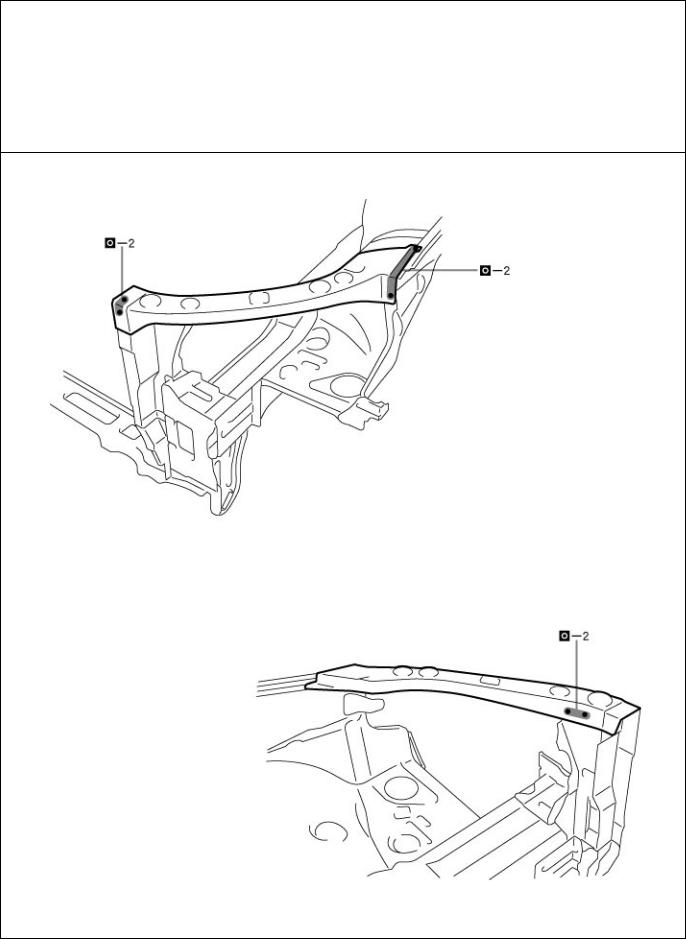

RADIATOR UPPER SUPPORT (ASSY)

REMOVAL

F14459-A

F14459

|

BP-2 |

BODY PANEL REPLACEMENT |

INSTALLATION

STemporarily install the new parts and measure each part of the new parts in accordance with the body dimension diagram. (See the body dimension diagram)

SInspect the fitting of the related parts around the new parts before welding. This affects the appearance of the finish.

SAfter welding, apply the polyurethane foam to the corresponding parts.

SAfter welding, apply body sealer and under-coating to the corresponding parts.

SAfter applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

F14460

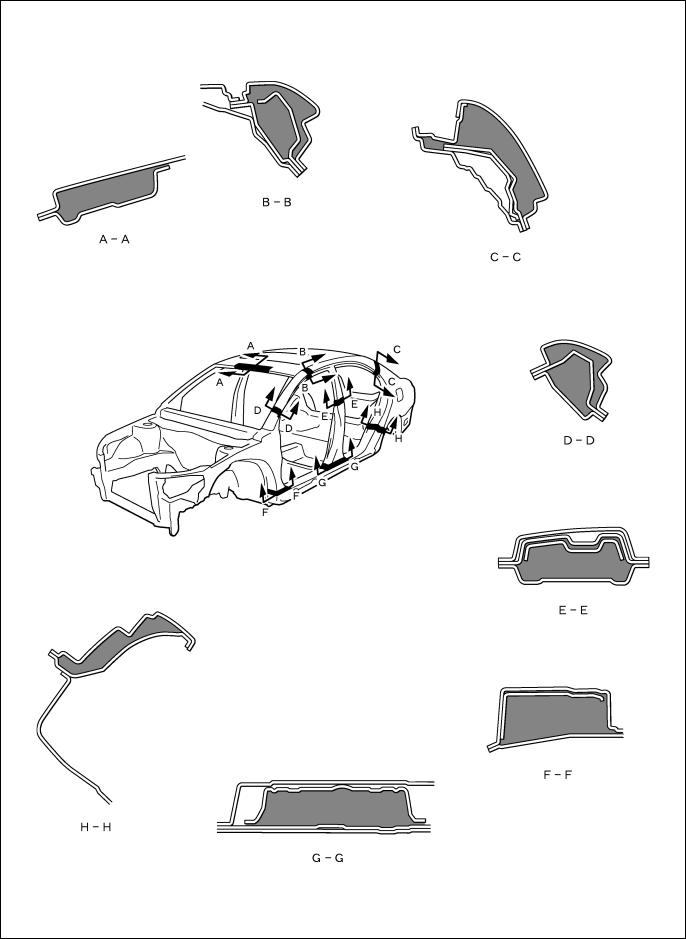

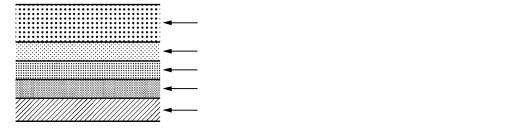

BODY PANEL ANTI-CHIPPING PAINT APPLICATION AREAS

HINT:

1)Anti-chipping paint should be applide to some areas before the second coat and to others after the top coat.

2)If other areas are accidentally coated, wipe of the paint immediately with a rag soaked in grease, wax and silicone remover.

PVC Chipping Primer

Urethane Primer

Soft — Chip Primer (Poly Olefine)

F14419

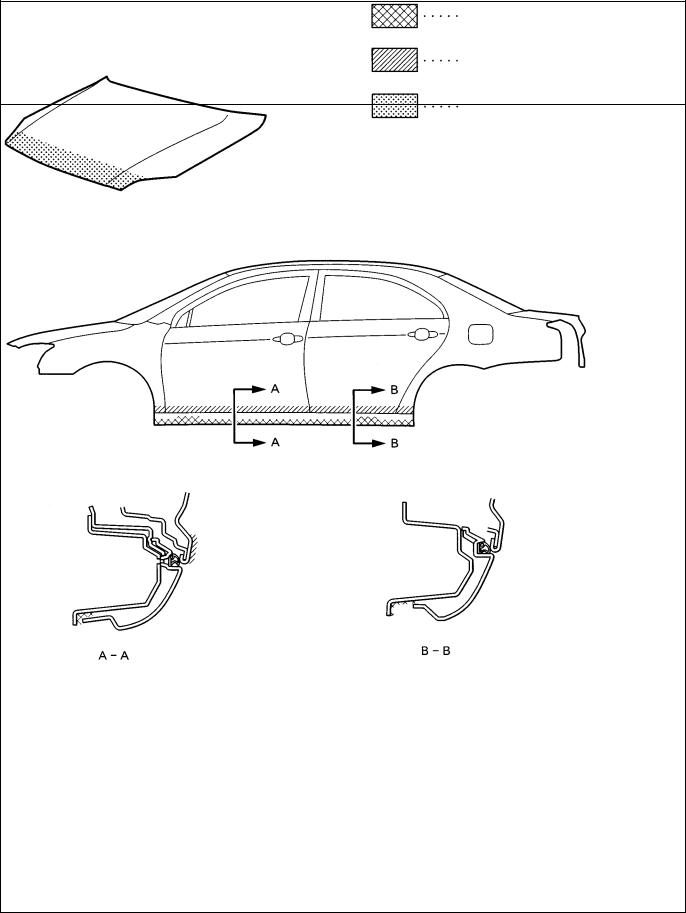

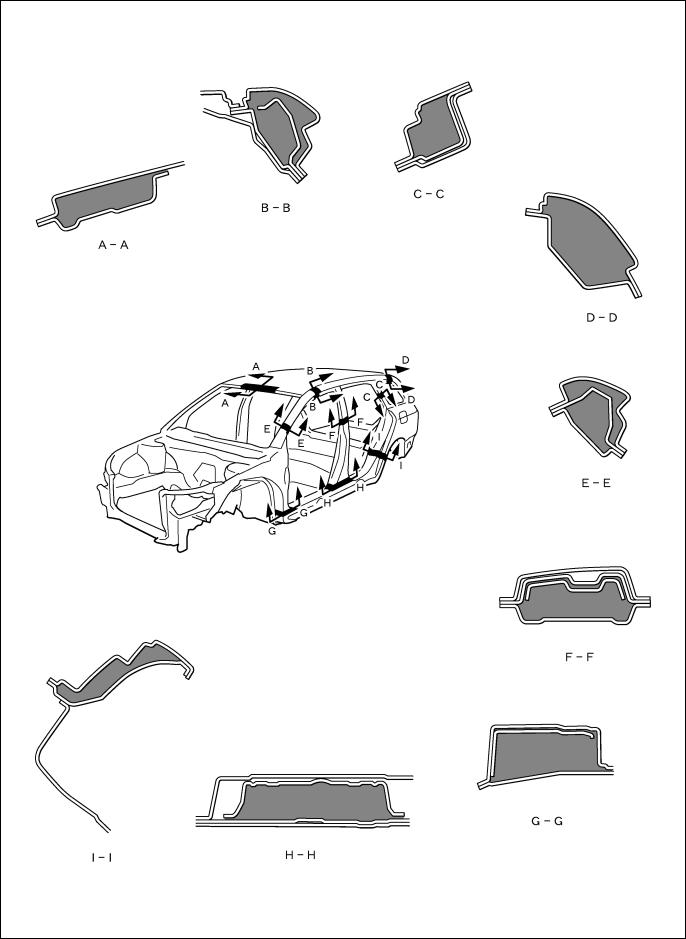

SILENCER SHEET INSTALLATION AREAS

Thickness of Asphalt Sheet

1.6mm (0.063in.)

1.8mm (0.071in.)

3.0mm (0.118in.)

F14418

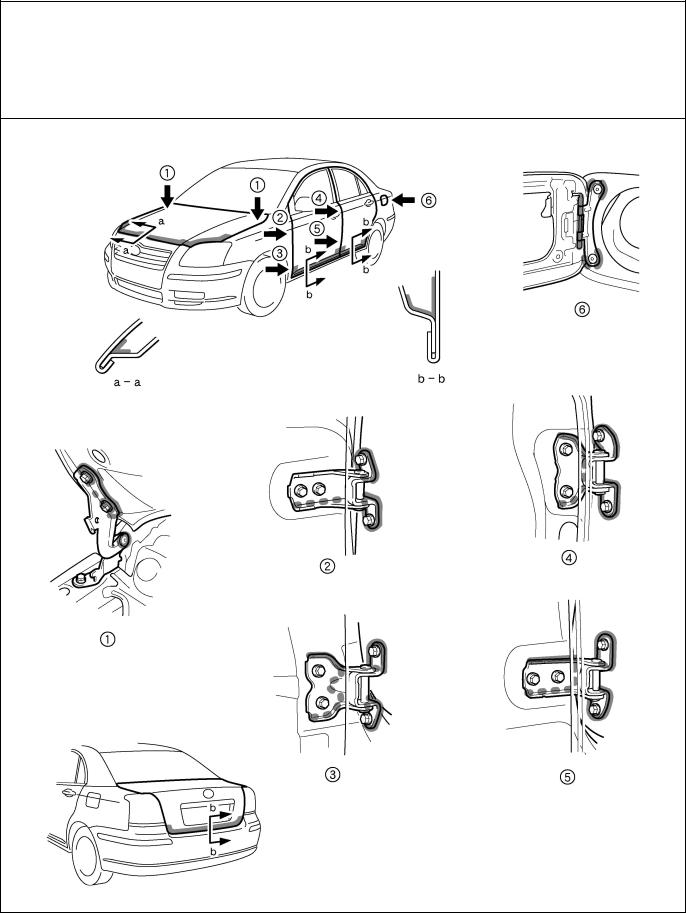

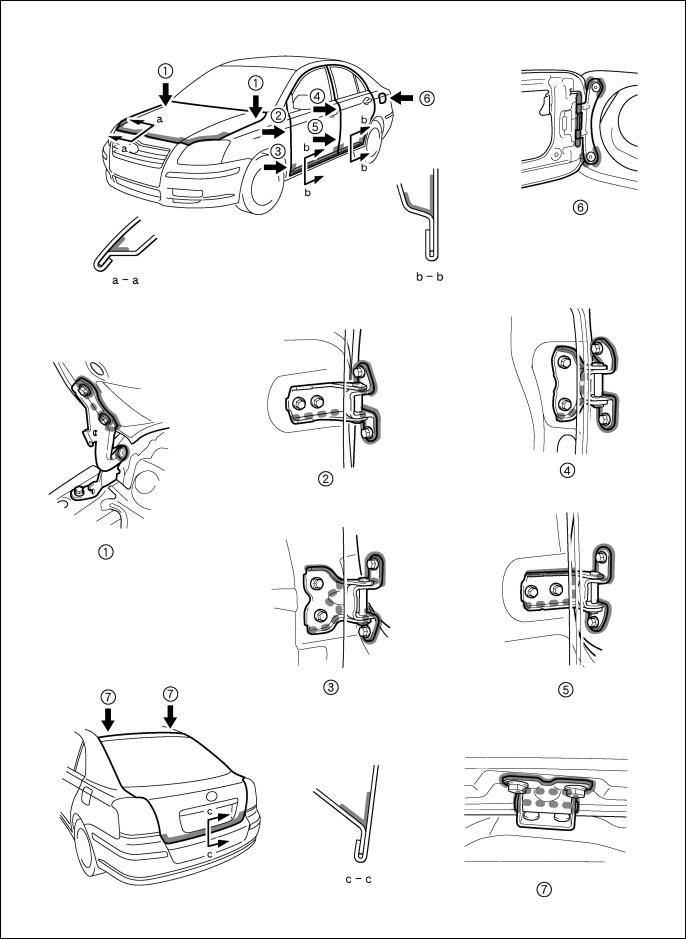

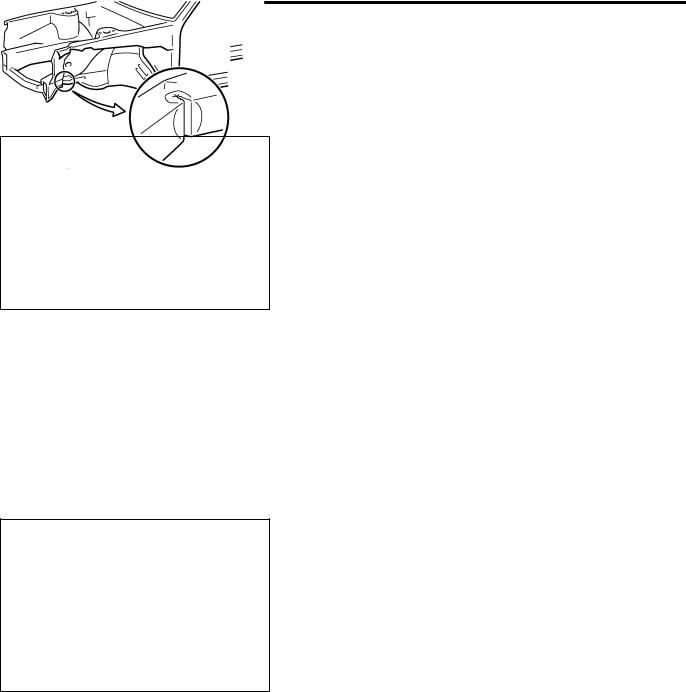

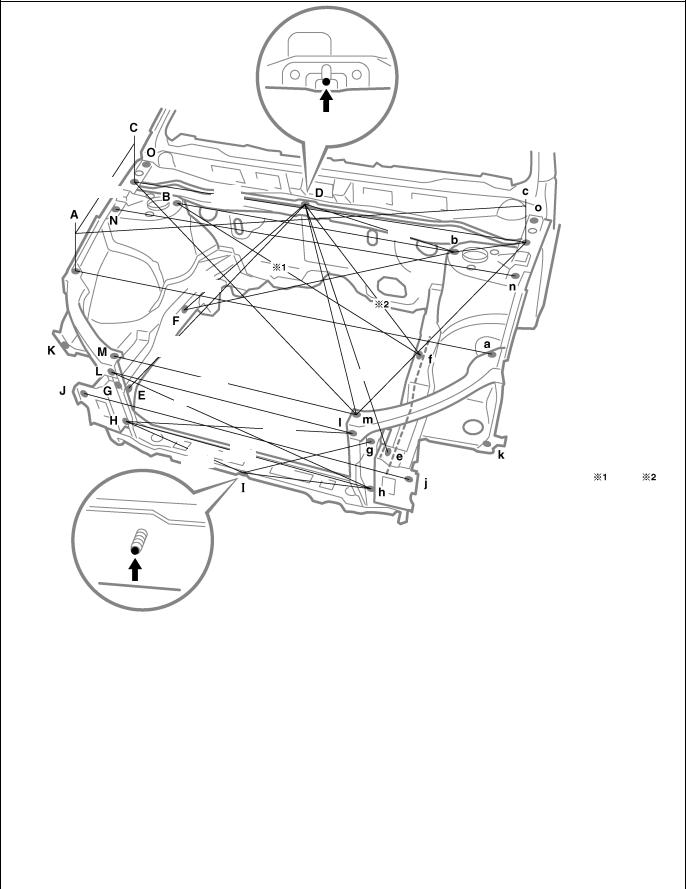

BODY PANEL ANTI-RUST AGENT (WAX) APPLICATION AREAS

HINT:

1)Whenever adjusting the doors and hoods, apply anti-rust agent (wax) around the hinges.

2)Even if partially repairing a part, apply anti-rust agent (wax) over the entire application area of the part.

3)Wipe off the anti-rust agent immediately with a rag soaked in a grease, wax and silicone remover, if accidently applied to other areas.

[Sedan]

F14412

F14414

F14413

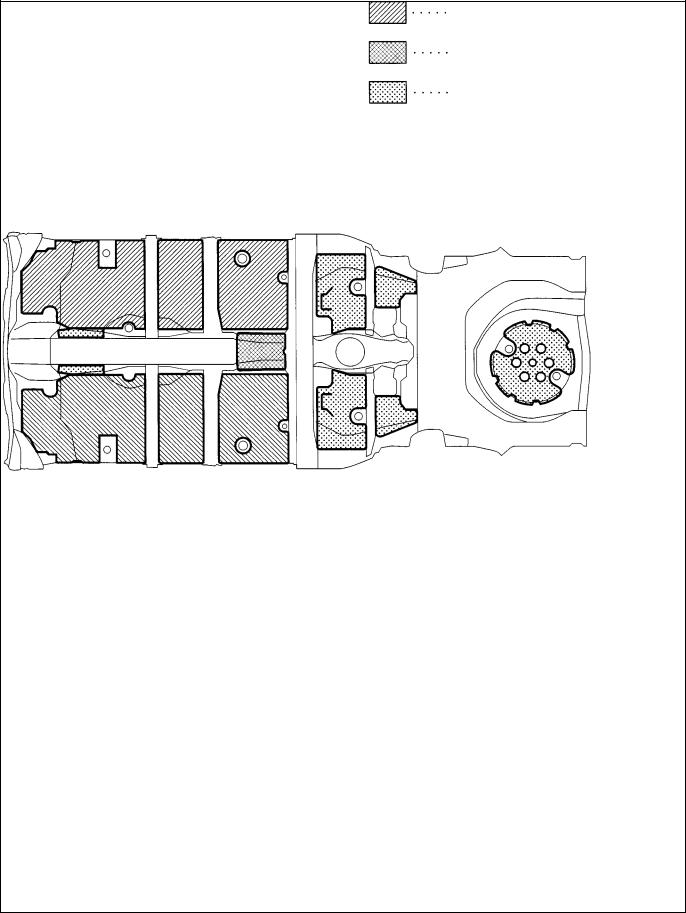

FOAMED MATERIAL APPLICATION AREAS

The sections shown in the figure below are filled with foamed material to provide noise insullation. After repairing these sections or their peripheries, refill with foamed materials

HINT:

1)Use the service holes located on the reverse side of the body panel to refill with foamed materials.

2)When handling foamed material, follow the directions of the material’s manufacturer.

[Sedan]

F14415

F14417

F14416

BODY PANEL UNDERCOATING AREAS

HINT:

1)First wipe off any dirt, grease or oil with a rag soaked in a grease, wax and silicone remover.

2)Cover the surrounding areas with masking paper to avoid coating unnecessary areas. If other areas are accidently coated, wipe off the coating immediately.

3)Apply the first coating of undercoat to all welded areas and panel joints, then apply a second coat over the entire area.

4)Do not coat parts which become hot, such as the tailpipe, or moving parts, such as the propeller shaft.

5)Besides the locations described below, apply undercoating to all weld points under the body to insure corrosion prevention.

6)Be sure to seal the edge of the flange of the member and bracket with undercoating.

7)If undercoat is damaged by peeling, cracks, etc., be sure to repair as necessary.

F14411

REFERENCE

Referring to the notes above, undercoating should be applied according to the specifications for your country.

Antilock Brake System Air Conditioner assembly

Electronic Controlled Transmission Electronic Control Unit

Exempli Gratia (for Example) Except

Front Wheel Drive Vehicles

Four Wheel Drive Vehicles inch

Left-hand Left-hand Drive Metal Inert Gas Model Year

Progressive Power Steering Right-hand

Right-hand Drive Supplemental Restraint System Special Service Materials

with without

ABBREVIATIONS USED IN THIS MANUAL

For convenience, the following abbreviations are used in this manual.

ABS

A/C assy ECT ECU e.g.

Ex.

FWD 4WD in.

LH

LHD

MIG

M/Y

PPS

RH

RHD

SRS

SSM w/ w/o

IN-16

INTRODUCTION

PRECAUTIONS FOR REPAIRING BODY STRUCTURE PANELS

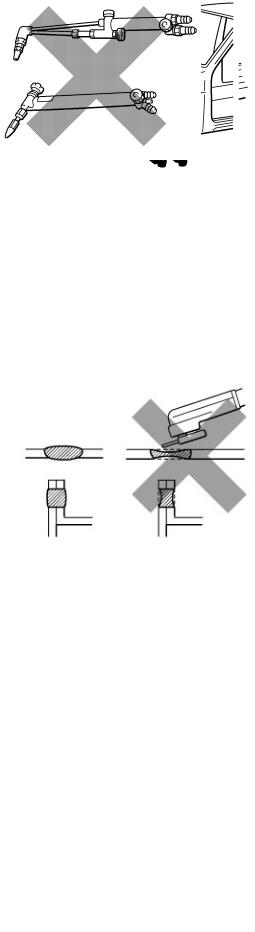

1.HEAT REPAIR FOR BODY STRUCTURE PANELS

Toyota prohibits the use of the heat repair method on body structure panels when repairing a vehicle damaged in a collision.

Panels that have high strength and rigidity, as well as a long life span for the automobile body are being sought after. At Toyota, in order to fulfill these requirement, we use high tensile strength steel sheets and rust preventive steel sheets on the body.

High tensile steel sheets are made with alloy additives and a special heat treatment in order to improve the strength. To prevent the occurrence of rust for a long period of time, the surface of the steel is coated with a zinc alloy.

If a body structure parts are heat repaired with an acetylene torch or other heating source, the crystalline organization of the steel sheet will change and the strength of the steel sheet will be reduced.

The ability of the body to resist rust is significantly lowered as well since the rust resistant zinc coating is destroyed by heat and the steel sheet surface is oxidized.

2.STRUCTURE PANEL KINKS

A sharp deformation angle on the panel that cannot be returned to its original shape by pulling or hammering is called a kink.

Since structure parts were designed to exhibit a 100% performance when they were in their original shape, if they are deformed in an accident, or if the deformed parts are repaired and reused, they become unable to exhibit the same performance as intended in the design.

It is necessary to replace the part where the kink has occurred.

3.IMPACT BEAM REPAIR

The impact beam and bracket are necessary and important parts in maintaining a survival space for passengers in a side collision.

For impact beam, we use special high tensile strength steel.

The high tensile strength steel maintains its special crystalline organization by heat treatment or alloy additives. Since these parts were designed to exhibit a 100% performance when they were in their original shape, if they are deformed in an accident, or if the deformed parts are repaired and reused, they become unable to exhibit the same performance as intended in the design.

It is necessary to replace the door assembly when impact beam or bracket is damaged.

HANDLING PRECAUTIONS ON RELATED COMPONENTS

1.BRAKE SYSTEM

The brake system is one of the most important safety components. Always follow the directions and notes given in section BR of the repair manual for the relevant model when handling brake system parts.

NOTICE: When repairing the brake master cylinder or TRAC system, bleed the air out of the TRAC system.

2.DRIVE TRAIN AND CHASSIS

The drive train and chassis are components that can have great effects on the running performance and vibration resistance of the vehicle. After installing components in the sections listed in the table below, perform alignments to ensure correct mounting angles and dimensions. Particularly accurate repair of the body must also be done to ensure correct alignment.

HINT: Correct procedures and special tools are required for alignment. Always follow the directions given in the repair manual for the relevant model during alignment and section DI of this section.

|

Component to be aligned |

Section of repair manual |

|

|

for relevant model |

||

|

Front Wheels |

Front Suspension (26) section |

|

|

Rear Wheels |

Rear Suspension (27) section |

3.COMPONENTS ADJACENT TO THE BODY PANELS

Various types of component parts are mounted directly on or adjacently to the body panels. Strictly observe the following precautions to prevent damaging these components and the body panels during handling.

SBefore repairing the body panels, remove their components or apply protective covers over the components.

SBefore prying components off using a screwdriver or a scraper, etc., attach protective tape to the tool tip or blade to prevent damaging the components and the body paint.

SBefore removing components from the outer surface of the body, attach protective tape to the body to ensure no damage to painted areas.

HINT: Apply touch-up paint to any damaged paint surfaces.

SBefore drilling or cutting sections, make sure that there are no wires, etc. on the reverse side.

4.ECU (ELECTRONIC CONTROL UNIT)

Many ECUs are mounted in this vehicle.

Take the following precautions during body repair to prevent damage to the ECUs.

SBefore starting electric welding operations, disconnect the negative (–) terminal cable from the battery.

When the negative (–) terminal cable is disconnected from the battery, memory of the clock and audio systems will be cancelled. So before starting work, make a record of the contents memorized by each memory system. Then when work is finished, reset the clock and audio systems as before.

When the vehicle has tilt and telescopic steering, power seat and outside rear view mirror, which are all equipped with memory function, it is not possible to make a record of the memory contents.

So when the operation is finished, it will be necessary to explain this fact to the customer, and request the customer to adjust the features and reset the memory.

SDo not expose the ECUs to ambient temperatures above 80_C (176_F).

NOTICE: If it is possible the ambient temperature may reach 80_C (176_F) or more, remove the ECUs from the vehicle before starting work.

SBe careful not to drop the ECUs and not to apply physical shocks to them.

PROPER AND EFFICIENT WORK

PROCEDURES

1.REMOVAL

(a)PRE-REMOVAL MEASURING

(1)Before removal or cutting operations, take measurements in accordance with the dimension diagram. Always use a puller to straighten a damaged body or frame.

F10007

Cutting Okay

Reinforcement

Corners

F10008A

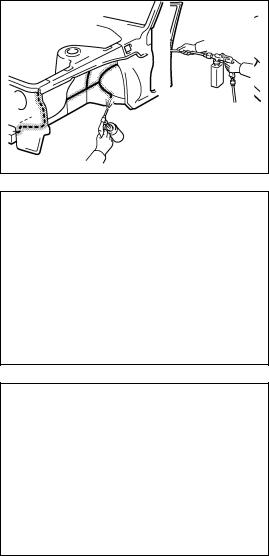

(b)CUTTING AREA

(1)Always cut in a straight line and avoid reinforced area.

(c)PRECAUTIONS FOR DRILLING OR CUTTING

(1)Check behind any area to be drilled or cut to insure that there are no hoses, wires, etc., that may be damaged.

HINT: See “Handling Precautions on Related Components” on page IN-15.

(d)REMOVAL OF ADJACENT COMPONENTS

(1)When removing adjacent components, apply protective tape to the surrounding body and your tools to prevent damage.

HINT: See “Handling Precautions on Related Components” on page IN-15.

F10010

Less than 3mm

2.PREPARATION FOR INSTALLATION

(a)SPOT WELD POINTS

(1)When welding panels with a combined thickness of over 3mm (0.12in.), use a MIG (Metal Inert Gas) welder for plug welding.

HINT: Spot welding will not provide sufficient durability for panels over 3mm (0.12in.) thick.

F10011A

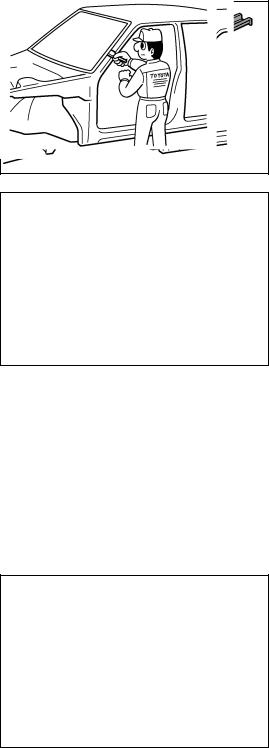

(b)APPLICATION OF WELD-THROUGH PRIMER (SPOT SEALER)

(1)Remove the paint from the portion of the new parts and body to be welded, and apply weld-through primer.

F10012

(c)MAKING HOLES FOR PLUG WELDING

(1)For areas where a spot welder cannot be used, use a puncher or drill to make holes for plug welding.

|

REFERENCE: |

mm (in.) |

||

|

Thickness of welded portion |

Size of plug hole |

||

|

Puncher |

1.0 (0.04) under |

5 (0.20) ø over |

|

|

1.0 (0.04) – 1.5 (0.06) |

6.4 (0.26) ø over |

||

|

F10013A |

1.5 (0.06) over |

8 (0.31) ø over |

|

(d)SAFETY PRECAUTIONS FOR ELECTRICAL COMPONENTS

(1)When welding, there is a danger that electrical components will be damaged by the electrical current flowing through the body.

(2)Before starting work, disconnect the negative terminal of the battery and ground the welder near the welding location of the body.

F10014

|

20 X 30mm |

|

|

Air Saw |

Overlap |

F10015A

(e)ROUGH CUTTING OF JOINTS

(1)For joint areas, rough cut the new parts, leaving 20 – 30mm (0.79 – 1.18in.) overlap.

|

Body |

|

|

Measurement |

|

|

Diagrams |

F10016A |

|

WRONG |

F10017A |

|

CORRECT |

WRONG |

|

F10018A |

|

|

Tip Cutter |

F10019A |

|

New Spot |

|

|

Old |

Locations |

|

Spot |

|

|

Locations |

|

|

F10020A |

3.INSTALLATION

(a)PRE-WELDING MEASUREMENTS

(1)Always take measurements before installing underbody or engine components to insure correct assembly. After installation, confirm proper fit.

(b)WELDING PRECAUTIONS

(1)The number of welding spots should be as follows.

Spot weld: 1.3 X No. of manufacturer’s spots. Plug weld: More than No. of manufacturer’s plugs.

(2)Plug welding should be done with a MIG (Metal Inert Gas) welder. Do not gas weld or braze panels at areas other than specified.

(c)POST-WELDING REFINISHING

(1)Always check the welded spots to insure they are secure.

(2)When smoothing out the weld spots with a disc grinder, be careful not to grind off too much as this would weaken the weld.

(d)SPOT WELD LOCATIONS

(1)Try to avoid welding over previous spots.

(e)SPOT WELDING PRECAUTIONS

(1)The shape of the welding tip point has an effect on the strength of the weld.

(2)Always insure that the seams and welding tip are free of paint.

4.ANTI-RUST TREATMENT

(a)BODY SEALER APPLICATION

(1)For water-proofing and anti-corrosion measures, always apply the body sealer to the body panel seams and hems of the doors, hoods, etc.

(b)UNDERCOAT APPLICATION

(1)To prevent corrosion and protect the body from damage by flying stones, always apply sufficient undercoat to the bottom surface of the under body and inside of the wheel housings.

F10022

5.ANTI-RUST TREATMENT AFTER PAINTING PROCESS

(a)ANTI-RUST AGENT (WAX) APPLICATION

(1)To preserve impossible to paint areas from corrosion, always apply sufficient anti-rust agent (wax) to the inside of the hemming areas of the doors and hoods, and around the hinges, or the welded surfaces inside the boxed cross-section structure of the side member, body pillar, etc.

F10023

6.ANTI-RUST TREATMENT BY PAINTING

REFERENCE:

Painting prevents corrosion and protect the sheet metal from damage. In this section, anti-chipping paint only for anti-corrosion purpose is described.

(a)ANTI-CHIPPING PAINT

(1)To prevent corrosion and protect the body from damage by flying stones, etc., apply anti-chipping paint to the rocker panel, wheel arch areas, balance panel, etc.

HINT:

Depending on the model or the application area, there are cases where the application of anti-chipping paint is necessary before the second coat or after the top coat.

|

S Apply the anti-chipping paint after |

S |

Apply the anti-chipping paint before |

|

the top coat. |

the second coat. |

|

|

Anti-Chipping Paint |

Top Coat |

|

|

Second Coat |

||

|

Top Coat |

||

|

Anti-Chipping Paint |

||

|

Second Coat |

||

|

Under Coat (ED Primer) |

Under Coat (ED Primer) |

|

|

Steel Metal |

Steel Metal |

|

|

F10024A |

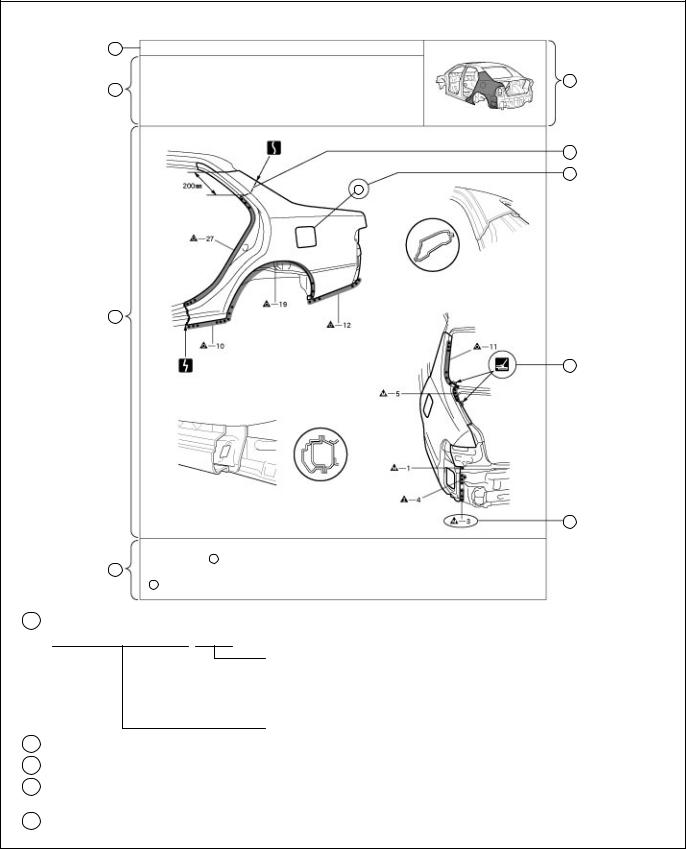

HOW TO USE THIS MANUAL

1.BODY PANEL REPLACEMENT THIS MANUAL

|

BP-34 |

BODY PANEL REPLACEMENT |

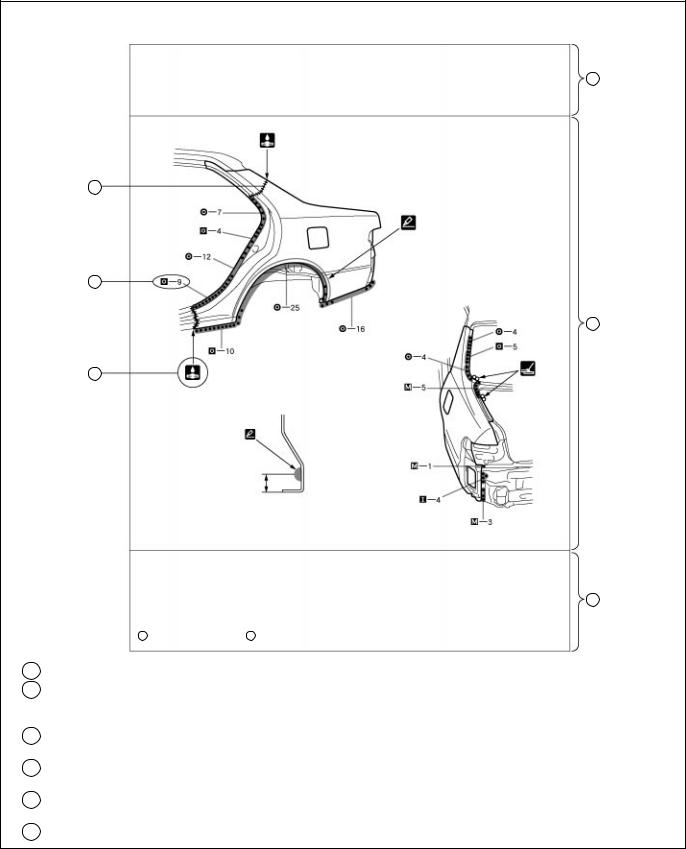

A QUARTER PANEL (CUT)

REMOVAL

C

B

I

K

A

D

I

J

POINT

1 Remove the A at the same time.

A Fuel Filler Opening Lid

A : REPLACEMENT PART AND METHOD

QUARTER PANEL (CUT)

Replacement method

(ASSY) … Assembly replacement

(CUT) … Major cutting (less than 1 / 2 of part used) (CUT-H) … Half cutting (about 1 / 2 of part used) (CUT-P) … Partial cutting (most of part used)

Replacement part

B: REMOVAL CONDTIONS

C: PART LOCATION

D: REMOVAL DIAGRAM

Describes in detail removal of the damaged part involving repair by cutting.

E : REMOVAL GUIDE

Provides additional information to more efficiently help you perform the removal.

F13890A

|

BODY PANEL REPLACEMENT |

BP-35 |

INSTALLATION

STemporaily install the new parts and measure each part of the new parts in accordance with the body dimension diagram. (See the body dimension diagram)

SInspect the fiting of the related parts around the new parts before welding. This affects the appearance of the finish.

SAfter welding, apply the polyurethane foam to the corresponding parts.

SAfter welding, apply body sealer and under-coating to the corresponding parts.

SAfter applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

I

J

I

1Before temporarily installing the new parts, apply body sealer to the wheel arch.

HINT:

1)Apply body sealer about 5mm (0.20in.) front the flange, avoiding any oozing.

2)Apply sealer evenly, about 3 – 4mm (0.12 – 0.16in.) in diameter.

3)For other sealing points, refer to section PC.

H

PART NAME

|

A Fuel Filler Opening Lid |

B Waterproof Rivet |

F: INSTALLATION CONDITIONS

G: INSTALLATION DIAGRAM

Describes in detail installation to the new part involving repair by welding and / or cutting, but excluding painting.

H : INSTALLATIOLN GUIDE

Provides additional information to more efficiently help you perform the installation.

I : SYMBOLS

(See page IN-7)

J : ILLUSTRATION OF WELD POINTS

Weld method and panel position symbols (See page IN-9)

K : PART NAME

F13891A

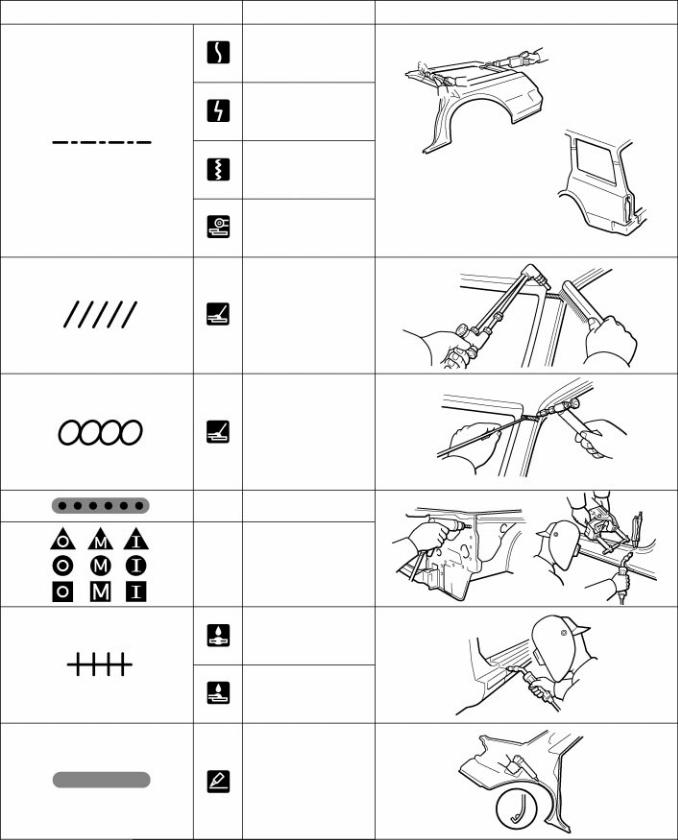

2.SYMBOLS

The following symbols are used in the welding diagrams in section BP of this manual to indicate cutting areas and the types of weld required.

|

SYMBOLS |

MEANING |

ILLUSTRATION |

CUT AND JOIN LOCATION

(SAW CUT)

CUT AND JOIN LOCATION (Cut Location for

Supply Parts)

CUT LOCATION

CUT WITH DISC

SANDER, ETC.

BRAZE (Removal)

BRAZE (Installation)

—WELD POINTS

SPOT WELD OR

—MIG PLUG WELD (See Page IN-9)

CONTINUOUS MIG WELD (BUTT WELD)

CONTINUOUS MIG WELD (TACK WELD)

BODY SEALER

F13893A

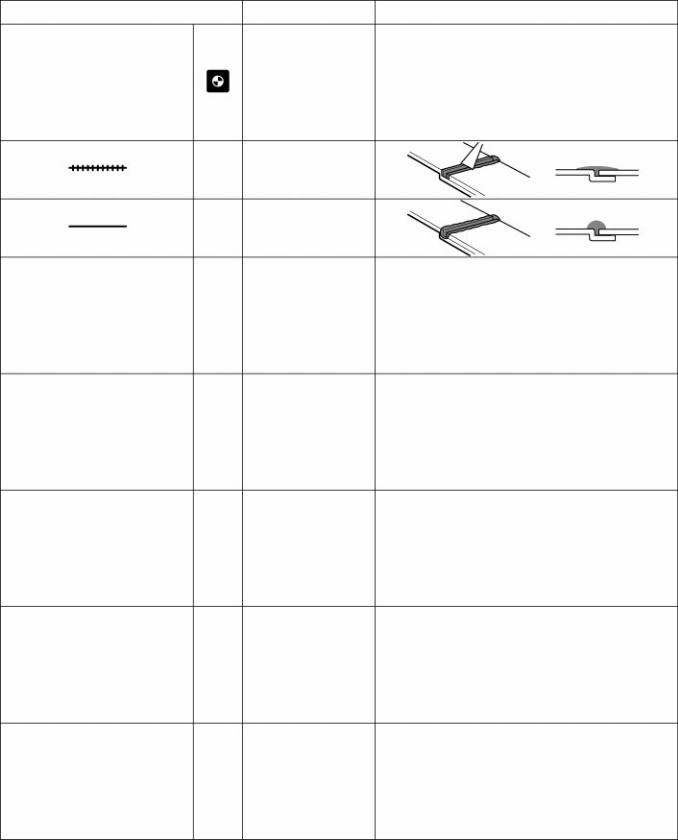

|

SYMBOLS |

MEANING |

ILLUSTRATION |

BODY SEALER

—(Flat Finishing)

BODY SEALER

—(No flat Finishing)

F13894A

3. ILLUSTRATION OF WELD POINT SYMBOLS EXAMPLE:

Weld points

Remove weld point and panel position

|

SYMBOLS MEANING |

ILLUSTRATION |

Remove

Weld

Points

(Outside)

(Middle)

(Inside)

HINT: Panel position symbols are as seen from the working posture.

Weld points

Weld method and panel position

|

SYMBOLS MEANING |

ILLUSTRATION |

Spot Weld

MIG Plug

Weld

Spot MIG

Weld

F13892A

Glass Cover

Seat Cover

F10001A

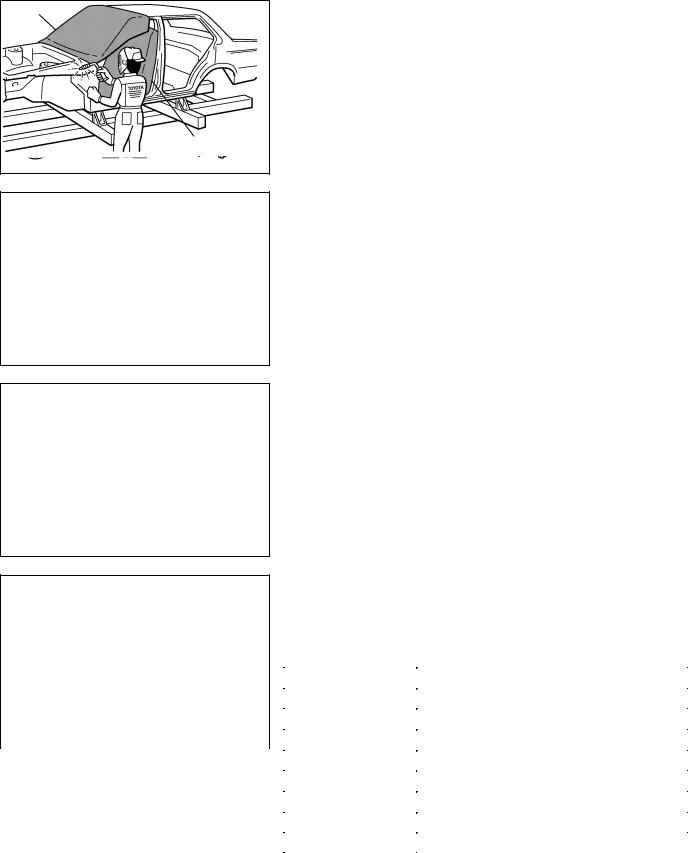

GENERAL REPAIR INSTRUCTIONS

1.WORK PRECAUTIONS

(a)VEHICLE PROTECTION

(1)When welding, protect the painted surfaces, windows, seats and carpet with heat resistant, fire-proof covers.

(b)SAFETY

(1)Never stand in direct line with the chain when using a puller on the body or frame, and be sure to attach a safety cable.

WRONG

F10002A

(2)Before performing repair work, check for fuel leaks. If a leak is found, be sure to close the opening totally.

(3)If it is necessary to use a flame in the area of the fuel tank, first remove the tank and plug the fuel line.

(c)SAFETY WORK CLOTHES

(1)In addition to the usual mechanic’s wear, cap and safety shoes, the appropriate gloves, head protector, glasses, ear plugs, face protector, dust-prevention mask, etc. should be worn as the situation demands.

|

Code |

Name |

||

|

A |

Dust-Prevention Mask |

||

|

B |

Face Protector |

||

|

F10004 |

C |

Eye Protector |

|

|

D |

Safety Shoes |

||

|

E |

Welder’s Glasses |

||

|

F |

Ear Plugs |

||

|

G |

Head Protector |

||

|

H |

Welder’s Gloves |

2.HANDLING PRECAUTIONS OF PLASTIC BODY PARTS

(1)The repair procedure for plastic body parts must conform with the type of plastic material.

(2)Plastic body parts are identified by the codes in the following table.

(3)When repairing metal body parts adjoining plastic body parts (by brazing, frame cutting, welding, painting etc.), consideration must be given to the property of the plastic.

|

Heat* |

|||||

|

Code |

Material |

resistant |

Resistance to |

Notes |

|

|

name |

temperature |

alcohol or gasoline |

|||

|

limit _C (_F) |

|||||

|

Acrylonitrile |

80 |

Alcohol is harmless if applied only for |

Avoid gasoline and organic |

||

|

AAS |

short time in small amounts (e.g., quick |

||||

|

Acrylic Styrene |

(176) |

or aromatic solvents. |

|||

|

wiping to remove grease). |

|||||

|

Acrylonitrile |

80 |

Alcohol is harmless if applied only for |

Avoid gasoline and organic |

||

|

ABS |

short time in small amounts (e.g., quick |

||||

|

Butadiene Styrene |

(176) |

or aromatic solvents. |

|||

|

wiping to remove grease). |

|||||

|

Acrylonitrile |

80 |

Alcohol is harmless if applied only for |

Avoid gasoline and organic |

||

|

AES |

short time in small amounts (e.g., quick |

||||

|

Ethylene Styrene |

(176) |

or aromatic solvents. |

|||

|

wiping to remove grease). |

|||||

|

Acrylonitrile |

80 |

Alcohol is harmless if applied only for |

Avoid gasoline and organic |

||

|

ASA |

Styrene |

short time in small amounts (e.g., quick |

|||

|

(176) |

or aromatic solvents. |

||||

|

Acrylate |

wiping to remove grease). |

||||

|

Cellulose |

80 |

Alcohol is harmless if applied only for |

Avoid gasoline and organic |

||

|

CAB |

short time in small amounts (e.g., quick |

||||

|

Acetate |

(176) |

or aromatic solvents. |

|||

|

wiping to remove grease). |

|||||

|

Ethylene |

100 |