In this book, I teach the basics of Programmable Logic Controllers and how to program them, their uses and applications. This will give you the knowledge you need to start writing your own PLC programs immediately. I also teach some advanced topics of PLCs that will put you on the path to becoming an expert in programming PLCs. Therefore, before you finish reading this book, you will have a very clear understanding of ladder logic programming structure of and you will also be able to apply it to real-world industrial applications.

If you want to master PLC programming, the best thing to do is study and use real industrial applications such as those I provide in this book. This is because good scenarios and industrial applications will make you learn better and faster the features and functions of the RSLogix 500 software.

In this book, the methods I present are those that would usually be employed in real world industrial automation, and they are all you will ever need to know. So, you will find the knowledge you acquire from this book very helpful, especially if you have little or no knowledge of PLC programming, and also if you are any skillful PLC programmer, no matter the level of your skill.

If all you have is just a PLC user manual or if you only refer to the help contents in a PLC documentation, you will be far from acquiring the skills you need to become an expert in PLC programming. Therefore, you will find my book very helpful for acquiring PLC programming skills. Not only will it give you a good start if you have never laid your hands on a PLC before, it will also teach you some advanced tricks and techniques for designing and developing anything from small to complex programs using only RSLogix 500 software.

A question I am often asked by beginners is where they can download a free version of RSLogix 500 to practice. I provide in chapter 3 of this book links to web pages where you can download a free version of RSLogix 500 and a free version of the RSLogix Emulate 500. Therefore, you do not even need to order any PLC to start learning, running and testing a ladder logic program.

Not only do I show you how to obtain the above-mentioned Rockwell Automation software for free and without hassle, I also illustrate with very clear screenshots every step of the installation, configuration, navigation and how to use the software to write ladder logic programs.

RSLogix 500 is a software platform developed by Rockwell Automation

for programming and configuring a range of Allen-Bradley programmable logic

controllers (PLCs). RSLogix 500 is specifically designed for small to mid-sized

applications, making it a popular choice among industrial automation

professionals.

The RSLogix 500 software provides a user-friendly interface

for creating ladder logic programs, configuring I/O modules, and monitoring the

status of the PLC. It supports a wide range of Allen-Bradley PLCs, including

the SLC 500 and MicroLogix families, which are commonly used in small to

mid-sized applications.

With RSLogix 500, users can create ladder logic programs

using a drag-and-drop interface and a variety of pre-built logic blocks. The

software also includes a simulation mode, allowing users to test their programs

before deploying them to a live system.

RSLogix 500 is part of the Rockwell Automation Studio 5000

software suite, which includes other programming and configuration tools for

larger applications. However, for smaller projects, RSLogix 500 remains a

popular and cost-effective option.

Table of Contents

Introduction

What is RSLogix500?

Getting Started with RSLogix500

Creating a New Project

Adding and Configuring Devices

Programming in RSLogix500

Uploading and Downloading Programs

Troubleshooting in RSLogix500

Operating System

RSLogix 500 Download

Conclusion

Introduction

In the world of industrial automation, programming software plays a crucial role in controlling machines and processes. One such software is RSLogix500, which is widely used in the manufacturing industry to program and control Allen-Bradley PLCs (Programmable Logic Controllers).

If you’re new to RSLogix500, this guide will give you a basic understanding of what it is, how to use it, and some tips for troubleshooting.

What is RSLogix500?

RSLogix500 is a software package from Rockwell Automation that is used for programming Allen-Bradley PLCs. It is a Windows-based program that allows users to create, edit, monitor, and download ladder logic programs to control PLCs.

Ladder logic is a graphical programming language used for designing and implementing control circuits. It is based on the idea of connecting electrical components in a circuit diagram, where each rung of the ladder represents a logical instruction.

Getting Started with RSLogix500

Before you can start programming in RSLogix500, you need to have a basic understanding of ladder logic and how PLCs work. If you’re new to these concepts, it’s recommended that you read up on them first.

Once you’re ready to start using RSLogix500, you’ll need to download and install the software. You can get it from the Rockwell Automation website or through a local distributor.

Creating a New Project

When you first launch RSLogix500, you’ll be prompted to create a new project. This project will contain all the ladder logic programs and configurations for the PLCs you’re working with.

To create a new project, select «File» from the menu bar and then «New». You’ll be prompted to give your project a name and to select the type of PLC you’re using.

Adding and Configuring Devices

After you’ve created a new project, you’ll need to add and configure the devices that you want to control with your ladder logic program. This can be done through the «RSWho» window, which can be accessed from the toolbar or the «Tools» menu.

Once you’ve added your devices, you’ll need to configure them by setting their communication parameters and I/O modules. This is done through the «RSLogix500» window, which can be accessed from the «Controller Properties» dialog.

Programming in RSLogix500

Now that you’ve set up your project and devices, you’re ready to start programming in RSLogix500. The programming interface consists of a main ladder logic editor and various other tools and windows for monitoring and debugging.

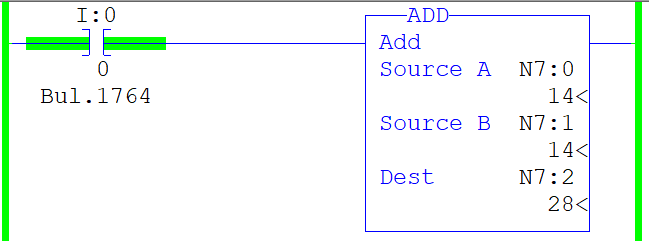

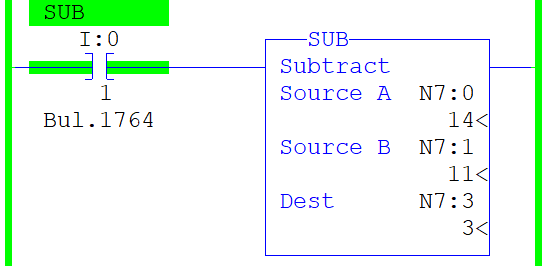

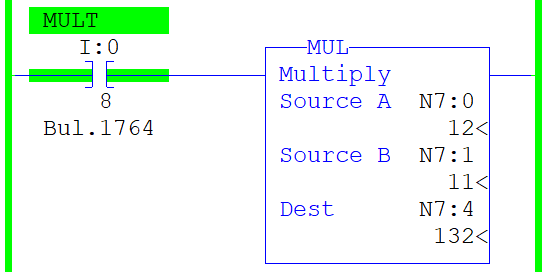

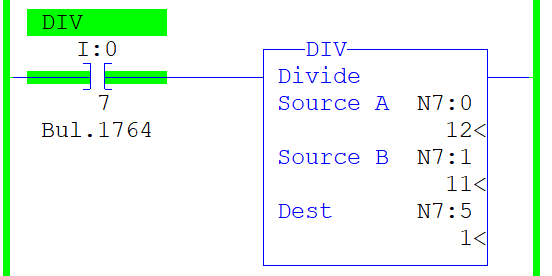

To add a new ladder logic program, right-click on the «Main Program» folder and select «New Routine». You can then drag and drop ladder logic instructions onto the rung editor and connect them using the various contact and coil symbols.

Uploading and Downloading Programs

Once you’ve finished programming your ladder logic program, you can upload it to the PLC to test it and make any necessary changes. This is done through the «Upload» and «Download» buttons on the toolbar.

To upload a program, connect to the PLC and select «Upload». This will retrieve the ladder logic program currently stored in the PLC and display it in RSLogix500. You can then make any necessary changes and download the updated program back to the PLC.

Troubleshooting in RSLogix500

When working with ladder logic programs, it’s important to have tools for monitoring and troubleshooting. RSLogix500 provides several tools for this purpose, including the «Program Status» window, which displays real-time information about the status of the ladder logic program.

If you encounter errors or issues with your ladder logic program, you can use the «Cross Reference» tool to trace the flow of signals and determine the source of the problem. You can also use the «Debug» tool to step through the program and observe its behavior.

Operating System:

- Windows 7 (32-bit and 64-bit)

- Windows 8 and 8.1 (32-bit and 64-bit)

- Windows 10 (32-bit and 64-bit)

Hardware Requirements:

- Intel Pentium 4 processor or higher

- 512 MB of RAM or more

- 2 GB of available hard disk space

- Display resolution of at least 1024×768

Software Requirements:

- Microsoft .NET Framework 4.0 or higher

- RSLinx Classic (version 2.56 or higher) for communication with Allen-Bradley PLCs

- Microsoft Excel (optional) for advanced data handling features

Installation:

RSLogix 500 is typically installed from a DVD or downloaded from the Rockwell Automation website.

During the installation process, you’ll be prompted to select the components you want to install, such as the RSLogix 500 software itself, RSLinx Classic, and any necessary drivers.

You may also be prompted to enter a serial number or activation key, depending on your licensing agreement with Rockwell Automation.

Updates:

- RSLogix 500 updates are typically released through the Rockwell Automation website.

- To install an update, download the update file and run the installer.

- Note that some updates may require you to first uninstall the previous version of RSLogix 500 before installing the new version.

Compatibility:

- RSLogix 500 is designed to work with Allen-Bradley PLCs, including the SLC 500 and MicroLogix series.

- It may not be compatible with other PLC brands or models.

- It’s important to check the compatibility of your hardware and software before installing RSLogix 500.

- Overall, RSLogix 500 is a robust programming software that requires a relatively modest set of hardware and software requirements. As long as your system meets these requirements and is compatible with Allen-Bradley PLCs, you should be able to install and use RSLogix 500 with ease.

RSLogix 500 Download

Click on below button to start RSLogix 500 Download:

Download now

Password:123

Conclusion

RSLogix500 is a powerful and versatile programming software that is widely used in industrial automation. With its intuitive ladder logic editor and robust set of tools for monitoring and troubleshooting, it’s an essential tool for anyone working with Allen-Bradley PLCs.

By following the steps outlined in this guide, you should be able to get started with RSLogix500 and begin creating your own ladder logic programs. As you become more familiar with the software, you’ll be able to take advantage of its more advanced features and create even more complex control systems.