Ну спасибо друг HiluxMafia, от души спасибо. Сегодня четыре часа убил что бы скачать эту книгу через торент и так , хифига не нашел — нет в доступе. А тут вуаля пользуйтесь на здоровье. Спасибо камрад.

Ну спасибо друг HiluxMafia, от души спасибо. Сегодня четыре часа убил что бы скачать эту книгу через торент и так , хифига не нашел — нет в доступе. А тут вуаля пользуйтесь на здоровье. Спасибо камрад.

Пожалуйста =)

***Hidden content cannot be quoted.***

Добрый день, не видно мануала, пишет скрытый контент, необходимо 5 сообщений Что делать???

Добрый день, не видно мануала, пишет скрытый контент, необходимо 5 сообщений Что делать???

написал в ЛС

добрый день, ищу ответ по ремонту замка задней двери! В мануале есть что-то похожее?!

добрый день, ищу ответ по ремонту замка задней двери! В мануале есть что-то похожее?!

Добрый, а что конкретно с замком?

нет фиксации в конечном положении. Доводчик срабатывает на закрытие и через секунду открывается снова… Разборка и чистка к сожалению результата не дали. Ищу ответ

нет фиксации в конечном положении. Доводчик срабатывает на закрытие и через секунду открывается снова… Разборка и чистка к сожалению результата не дали. Ищу ответ

У меня другая проблема была, не работала кнопка открытия 5 двери, диагностика показала излом проводки в месте перегибания сверху двери где идёт пучок проводов к двери. Вот так, может у вас тоже проблема там?

Максим123456789

Попробуй скачать и открыть с помощью браузера Windows.

Есть в этом мануале на праворукий схемы стеклоподъемников?

Есть в этом мануале на праворукий схемы стеклоподъемников?

разводки электрики или сама схема установки ?

Toyota Hilux Surf (N210, Mark IV, 4Runner 210W/215W, SW4, Hilux AN10/AN20/AN30) с бензиновыми двигателями: 3RZ-FE/2TR-FE 2.7 л (2693 см³) 150-163 л.с./110-120 кВт, 5VZ-FE 3.4 л (3378 см³) 185 л.с./136 кВт и дизельными 1KD-FTV 3.0 л (2982 см³) 170-173 л.с./125-127 кВт; Пошаговое описание процедур по эксплуатации, ремонту и техническому обслуживанию, диагностика, технические характеристики, особенности конструкции. Производственно-практическое издание автомобиль повышенной проходимости J-класса Тойота ХайЛюкс Сёрф (4Раннер, пикап ХайЛюкс 7) среднеразмерный рамный внедорожник с цельнометаллическими кузовами пятидверный универсал повышенной вместимости задне- и полноприводные модели седьмого поколения выпуска (включая рестайлинг 2005) с 2002 по 2009 год

ЕСЛИ ВЫ ВИДИТЕ ОШИБКУ 406 Not Acceptable и не видите документ, то скорей всего у Вас IP РФ и его надо сменить, на любой другой страны, с помощью VPN ( Scribd и SlideShare блокируют посетителей с Российским IP).

Видео Toyota Hilux Surf N210 (4Runner 210W/215W) замена передних тормозных колодок и радиатора отопителя салона (печки) системы охлаждения (Тойота ХайЛюкс Сюрф (4Раннер) 02-09)

Toyota Hilux Surf Mark IV (4Runner N210), Hilux VII общая информация (Тойота ХайЛюкс Сюрф (ФоРаннер), ХайЛюкс 2002-2009)

Передние тормоза

Снятие и установка

Примечание: установка производится в порядке, обратном снятию.

1. Снимите переднее колесо.

Момент затяжки ………… 112 Нм

2. Слейте тормозную жидкость из системы.

3. Снимите пружинные фиксаторы.

4. Снимите держатель колодок.

5. Снимите тормозные колодки.

6. Снимите антискрипные накладки.

7. Снимите тормозной суппорт.

а) Отсоедините тормозную трубку от суппорта.

Момент затяжки ………… 15 Нм

б) Отверните два болта и снимите тормозной цилиндр .

Момент затяжки ………… 123 Нм

8. Нанесите установочные метки на тормозной диск и ступицу и снимите тормозной диск.

Проверка

1. Измерьте толщину накладок тормозных колодок.

Номинальная толщина ………… 11,5 мм

Минимальная толщина ………… 1,0 мм

Замените колодки, если толщина накладок меньше минимальной или если заметен неравномерный износ.

2. Измерьте толщину тормозного диска.

Номинальная толщина ………… 28,0 мм

Минимальная толщина ………… 26,0 мм

Если диск имеет царапины, изношен или толщина диска меньше минимальной , замените диск.

3. Измерьте биение тормозного диска на расстоянии 10 мм от внешнего края тормозного диска.

Максимальное биение диска ………… 0,05 мм

Если биение большее максимального, замените тормозной диск.

Примечание: перед измерением биения убедитесь, что люфт подшипника ступицы находится в допустимых пределах.

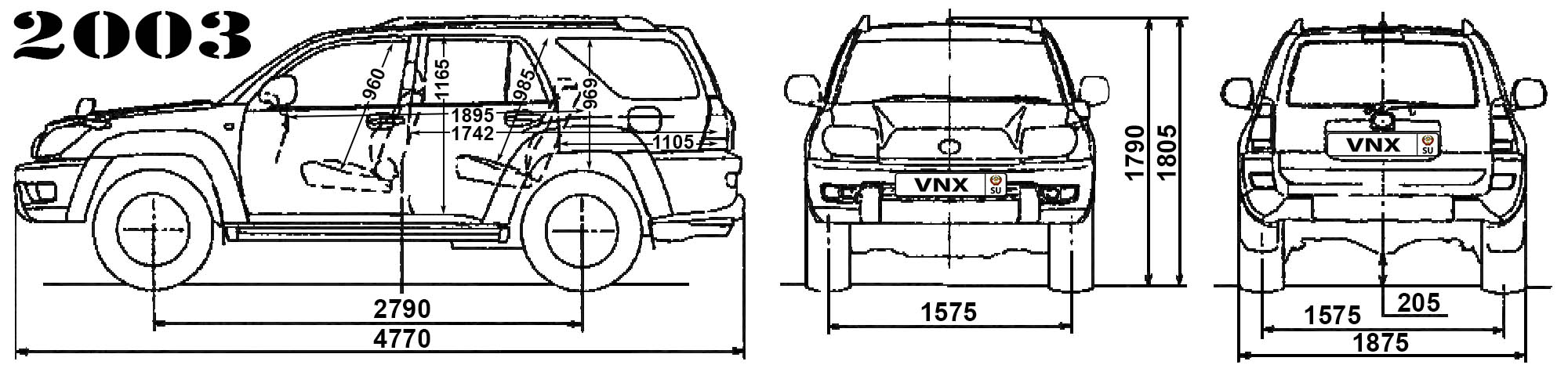

| № | Спецификация / Specs | Данные |

| Габариты (мм/mm) и масса (кг/kg) / Dimensions and Weight | ||

| 1 | Длина / Length | 4770-4801 |

| 2 | Ширина (без/с зеркалами) / Width | 1875 |

| 3 | Высота (загружен/пустой) / Height | 1750-1790/1805-1819 с багажником на крыше |

| 4 | Колёсная база / Wheelbase | 2790 |

| 5 | Дорожный просвет (клиренс) / Ground clearance | 205 |

| 6 | Снаряжённая масса / Total (curb) weight | 1880 |

| Полная масса / Gross (max.) weight | 2530 | |

|

Двигатель / Engine |

||

| 7 | Тип / Engine Type, Code | Бензиновый, жидкостного охлаждения, четырехтактный, 5VZ-FE |

| 8 | Количество цилиндров / Cylinder arrangement: Total number of cylinders, of valves | 6-цилиндровый, 24V, V-образный, DOHC с верхним расположением двух распределительных валов |

| 9 | Диаметр цилиндра / Bore | 93.5 мм |

| 10 | Ход поршня / Stroke | 82.0 мм |

| 11 | Объём / Engine displacement | 3378 см³ |

| 12 | Система питания / Fuel supply, Aspiration | Многоточечный впрыск топлива EFI |

| Атмосферный | ||

| 13 | Степень сжатия / Compression ratio | 9.6:1 |

| 14 | Максимальная мощность / Max. output power kW (HP) at rpm | 185 кВт (136 л.с.) при 4800 об/мин |

| 15 | Максимальный крутящий момент / Max. torque N·m at rpm | 294-303 Нм при 3600 об/мин |

|

Трансмиссия / Transmission |

||

| 16 | Сцепление / Clutch type | Гидротрансформатор с блокировкой / Torque Converter |

| 17 | КПП / Transmission type | Aisin-Warner Automatic A340F АКПП 4 Автоматическая, четырёхступенчатая, гидромеханическая, адаптивная, с двухступенчатой раздаткой и блокировкой межосевого дифференциала |

О Книге

- Название: Toyota Hilux Surf / Hilux Устройство, техническое обслуживание и ремонт

- Бензиновые двигатели: 3RZ-FE/2TR-FE 2.7 л (2693 см³) 150-163 л.с./110-120 кВт, 5VZ-FE 3.4 л (3378 см³) 185 л.с./136 кВт и дизельными 1KD-FTV 3.0 л (2982 см³) 170-173 л.с./125-127 кВт

- Выпуск с 2002 года

- Серия: «Ремонт Автомобилей»

- Год издания: 2010

- Автор: Коллектив авторов

- Издательство: «Ассоциация независимых издателей»

- Формат: PDF

- Страниц в книге: 529

- Размер: 100.32 МБ

- Язык: Русский

- Количество электросхем: 39

Скачать

Toyota Hilux Surf 4Runner,УСТРОЙСТВО ТЕХНИЧЕСКОЕ ОБСЛУЖИВАНИЕ РЕМОНТ

Пособие в формате PDF

(KZN185, RZM85, VZN1H5)

Модели 1995 — 2002 гг. выпуска с дизельным IKZ-TE (3,0 л) и бензиновыми 3RZ-FE (2,7л) и 5VZ-FE (3,4л) двигателями

Содержание

Сокращения и условные обозначения.

Идентификация

Общие инструкции по ремонту

Точки установки гаражного домкрата и лап подъемника

Руководство по эксплуатации

Техническое обслуживание и общие процедуры проверки и регулировки

Бензиновый двигатель 3RZ-FE механическая часть

Бензиновый двигатель 5VZ-FE — механическая часть

Дизельный двигатель 1KZ-TE — механическая часть

Двигатель — общие процедуры ремонта

Система охлаждения

И ДРУГОЕ

Ссылки: (скачать целиком)

бесплатно

Если есть вопросы — пишите в комментариях

(внизу страницы)

Скачать здесь >>

How to Use this Manual

2

Vehicle Identification Number

4

Engine Serial Number

4

Identification Information

4

General Repair Instructions

5

Precaution for Vehicles Equipped with a Catalytic Converter

8

Caution for Vehicles with Audio System with Built-In Anti-Theft System

8

Vehicle Lift and Support Locations

9

Abbreviations Used in this Manual

10

Glossary of Terms

12

Standard Bolt Torque Specifications

15

How to Determinte Bolt Strength

15

Specified Torque for Standard Bolts

16

Clutch Troubleshooting

18

Clutch Pedal Check and Adjustment

19

Clutch System Bleeding

20

Clutch Start System Inspection

20

Clutch Pedal Check

20

Clutch Start Switch Inspection and Adjustment

20

Inspection of Clutch Start Cancel Switch

21

Clutch Master Cylinder Components

23

Master Cylinder Removal

23

Master Cylinder Disassembly

23

Master Cylinder Inspection

24

Master Cylinder Reassembly

24

Master Cylinder Installation

25

Clutch Release Cylinder Components

26

Release Cylinder Removal

26

Relase Cylinder Disassembly

26

Release Cylinder Inspection

27

Relase Cylinder Assembly

27

Release Cylinder Installation

27

Clutch Unit Components

28

Clutch Unit Removal

28

Clutch Parts Inspection

29

Clutch Unit Installation

30

Manual Transmission

32

Manual Transmission

33

Manual Transmission — Precautions

35

Manual Transmission Troubleshooting

35

Transmission Removal and Installation

36

Transmission Removal Procedure

37

Transmission Installation

41

Transmission with Transfer Removal and Installation

45

Removal of Transmission with Transfer

47

Transmission with Transfer Installation

51

Transmission G58 Disassembly

57

Input Shaft Assembly Components

69

Output Shaft Assembly Components

71

Output Shaft Assembly Disassembly

71

Output Shaft Assembly Inspection

74

Output Shaft Assembly Assembly

76

Counter Gear Assembly and Reverse Idler Gear Components

80

Counter Gear Assembly Inspection

80

Replacement of Bearing — Counter Gear Assembly

81

Counter Gear Assembly Assembly

82

Reverse Idler Gear Inspection

83

Transfer Adaptor Components

84

Oil Seal Replacement

84

Reverse Restrict Pin Inspection and Replacement

84

Front Bearing Retainer Components

86

Transmission Assembly

87

Disassembly of Transmission Components

98

Disassembly of Transmission

99

Input Shaft Assembly Components View

108

Input Shaft Inspection

108

Output Shaft Assembly

110

Counter Gear Assembly and Reverse Idler Gear

118

Counter Gear Inspection

118

Inspection of Reverse Idler Gear

120

Extension Housing and Transfer Adaptor

121

Reverse Restrict Pin Inspection/Replacement

122

Front Bearing Retainer

124

Replacement of Oil Seal

124

Assembly of Transmission

125

W55 and W56 Manual Transmission

139

SST (Special Service Tools)

141

Recommended Tools

143

W55 and W56 Manual Transmission Troubleshooting

144

Transmission (W55 and W56) Removal and Installation

145

Transmission with Transfer Removal and Installation (W55 and W56)

146

Basic Subassembly Separation

149

Input Shaft Components

159

Input Shaft Inspection (W55 and W56)

159

Output Shaft Components

162

Output Shaft Disassembly

162

Output Shaft Component Parts Inspection

165

Output Shaft Assembly (W55 and W56)

167

Counter Gear and Reverse Idler Gear Components

170

Counter Gear Component Parts Disassembly

170

Counter Gear and Reverse Idler Gear Component Parts Inspection

171

Counter Gear Component Parts Assembly

174

Front Bearing Retainer Component

176

Oil Seal Replacement (W55 and W56)

176

Extension Housing and Transfer Adaptor Components

177

Reverse Restrict Pin Replacement

178

Basic Subassembly Reassembly

181

Manual Transmission (W55 and W56) Service Specifications

195

Automatic Transmission

198

A43D Automatic Transmission

200

A43D Automatic Transmission Sectional View

201

A43D Automatic Transmission Specifications

202

A43D Automatic Transmission Mechanical Operation

203

Automatic Transmission — Function of Components

204

Hydraulic Control System

207

Automatic Transmission Troubleshooting

208

Automatic Transmission Preliminary Check

211

Check Fluid Level

211

Check Fluid Condition

211

Inspect Throttle Cable

212

Inspect Shift Lever Position

212

Inspect Park/Neutral Position Switch

212

Inspect Idle Speed (N Position)

212

Overdrive Control System — Electronic Control Circuit View

213

Overdrive Control System — Troubleshooting Flow-Chart

214

Overdrive Control Components Inspection

215

Automatic Transmission — Mechanical System Tests

217

Stall Test

217

Time Lag Test

218

Hydraulic Test

219

Governor Pressure Test

220

Road Test

221

D Position Test

221

2 Position Test

222

L Position Test

222

R Position Test

223

P Position Test

223

Automatic Shift Schedule

224

Park Neutral Position Switch Inspection

224

Automatic Transmissoin On-Vehicle Repair

225

Valve Body Removal

225

Valve Body Installation

226

Parking Lock Pawl Removal

228

Parking Lock Pawl Installation

228

Throttle Cable Removal

228

Throttle Cable Installation

229

Extension Housing — Replacement of Oil Seal

230

Extension Housing Removal

230

Extension Housing Installation

232

Governor Body Removal

233

Governor Body Installation

233

Automatic Transmission Removal and Installation

235

Torque Converter Clutch and Drive Plate Inspection

237

A340E Automatic Transmission

239

A340E Automatic Transmission Specifications

240

A340E Automatic Transmission Mechanical Operation

241

A340E Automatic Transmission — Function of Components

242

A340E Automatic Transmission — Hydraulic Control System

245

A340E Automatic Transmission — Electronic Control System

246

Function of ECM

247

A340E Automatic Transmission Troubleshooting

248

A340E Automatic Transmission — Diagnosis System

251

Check «O/D Off» Indicator Light

251

Read Diagnostic Trouble Code

252

Cancel of Diagnostic Trouble Code

253

A340E Automatic Transmission — Troubleshooting Flow-Chart

254

A340E Automatic Transmission Preliminary Check

256

Manual Shifting Test

258

Electronic Control Circuit

260

Electronic Control Components

261

Electronic Control System — Troubleshooting Flow-Chart

262

No Shifting

262

Shift Point too High or too Low

264

No Up–Shift to Overdrive (after Warm–Up)

265

No Lock–Up (after Warm–Up)

266

TT Terminal Voltage Inspection

267

Electronic Control Components Inspection

268

A340E Automatic Transmission — Mechanical System Tests

271

Stall Test (A340E)

271

Time Lag Test (A340E)

272

Hydraulic Test (A340E)

273

Road Test (A340E)

275

Automatic Shift Schedule (A340E)

278

Park Neutral Position Switch Inspection (A340E)

280

A340E Automatic Transmission On-Vehicle Repair

281

Valve Body Removal (A340E)

281

Valve Body Installation (A340E)

282

Parking Lock Pawl Removal (A340E)

284

Throttle Cable Removal and Installation (A340E)

285

Extension Housing (A340E) — Oil Seal Replacement

286

Extension Housing (A340E) Removal

287

Extension Housing (A340E) Installation

288

Sensor Rotor Removal

289

Sensor Rotor Installation

290

A340E Transmission Removal and Installation

291

Torque Converter Clutch and Drive Plate Inspection (A340E)

293

A340H Automatic Transmission

295

A340H Automatic Transmission Specifications

296

A340H Automatic Transmission Mechanical Operation

297

A340H Automatic Transmission — Function of Components

298

Hydraulic Control System (A340H)

301

Electronic Control System (A340H)

302

A340H Transmission Troubleshooting

303

Diagnosis System Description (A340H)

306

Read Diagnostic Trouble Code (A340H)

307

Diagnostic Trouble Codes (A340H)

308

Cancel out Diagnostic Trouble Code (A340H)

308

Troubleshooting Flow-Chart (A340H)

309

A340H Automatic Transmission Preliminary Check

312

Manual Shifting Test (A340H)

315

Electronic Control System — Electronic Control Circuit (A340H)

317

TT Terminal Voltage Inspection (A340H)

325

Electronic Control Components Inspection (A340H)

326

Mechanical System Tests (A340H)

330

Stall Test (A340H)

330

Time Lag Test (A340H)

331

Hydraulic Test Preparation (A340H)

332

Road Test (A340H)

334

2 Position Test (A340H)

335

L Position Test (A340H)

336

R Position Test (A340H)

336

P Position Test (A340H)

337

Transfer Test (A340H)

337

Automatic Shift Schedule (A340H)

338

Transfer High-Low Shift Range

339

2 Position: High–Low Shift Possibility Range

340

D Position: High–Low Shift Possibility Range

340

Park Neutral Position Switch Inspection (A340H)

341

Low–High Shift Possibility Range (L, 2, D Position)

341

Transmission Valve Body Removal (A340H)

342

Transfer Valve Body Removal (A340H)

348

Valve Body And/Or Solenoid Valve Installation (A340H)

349

Throttle Cable Removal (A340H)

352

Throttle Cable Installation (A340H)

353

Parking Lock Pawl Removal and Installation (A340H)

355

Transmission (A340H) Removal and Installation

356

Torque Converter Clutch and Drive Plate Inspection (A340H)

358

A340F Automatic Transmission

361

A340F Automatic Transmission Specifications

362

A340F Automatic Transmission Mechanical Operation

363

A340F Automatic Transmission — Function of Components

364

Hydraulic Control System (A340F)

367

Line Pressure (A340F)

367

Throttle Pressure (A340F)

367

Electronic Control System (A340F)

368

ECM Function (A340F)

369

A340F Automatic Transmission Troubleshooting

370

Diagnosis System (A340F)

373

Read Diagnostic Trouble Code (A340F)

374

Diagnostic Trouble Codes (A340F)

375

Cancel of Diagnostic Trouble Code (A340F)

375

Troubleshooting Flow-Chart (A340F)

376

A340F Automatic Transmission Preliminary Check

378

Manual Shifting Test (A340F)

380

Electronic Control Circuit (A340F)

381

Electronic Control Components (A340F)

382

A340F Troubleshooting Flow-Chart

383

TT Terminal Voltage Inspection (A340F)

388

Electronic Control Components Inspection (A340F)

389

Mechanical System Tests (A340F)

393

Automatic Shift Schedule (A340F)

400

Park/Neutral Position Switch Inspection (A340F)

400

Valve Body Removal (A340F)

401

Valve Body Installation (A340F)

402

Parking Lock Pawl Removal (A340F)

405

Throttle Cable Removal (A340F)

405

Transmission Removal and Installation (A340F)

407

Torque Converter Clutch and Drive Plate Inspection (A340F)

409

Electrically Controlled Shift Lock System

410

Inspection of Electric Control Components

411

Mechanically Controlled Shift Lock System Components

412

Transfer Description and Specifications

414

Transfer Precautions

415

Transfer Troubleshooting

415

Transfer Removal

416

Transfer Installation

417

RF1A Type Transfer Components

419

Transfer Disassembly

420

Input Gear Components

425

Input Gear Bearing Replacement

425

Inspection of Hub Sleeve and Shift Fork Measure

426

Idler Gear Components

427

Idler Gear Bearing Replacement

427

Counter Gear Components

429

Counter Gear Bearings Replacement

429

Output Shaft Components View (Transfer)

431

Output Shaft Assembly Disassembly (Transfer)

431

Output Shaft Assembly Inspection (Transfer)

432

Output Shaft Assembly (Transfer)

434

Front Drive Gear Components

435

Front Drive Gear Bearings Replacement

435

Oil Seals Components

436

Oil Seals Replacement

436

Transfer Assembly

438

VF1A Type Transfer Components

444

Transfer Disassembly (VF1A)

446

Oil Pump Body Components

455

Oil Pump Body Inspection

456

Driven Sprocket Components

459

Driven Sprocket Disassembly

459

Driven Sprocket Assembly

460

Rear Output Shaft Assembly Components

461

Rear Output Shaft Assembly Disassembly

462

Rear Output Shaft Inspection Assembly

464

Rear Output Shaft Assembly Assembly

465

Input Shaft Components (VF1A)

468

Input Shaft Disassembly (VF1A)

468

Input Shaft Inspection (VF1A)

468

Input Shaft Assembly (VF1A)

469

Planetary Gear Components

470

Planetary Gear Inspection

470

Oil Seals Components (VF1A)

473

Oil Seals Replacement (VF1A)

473

Transfer Assembly (VF1A)

476

Propeller Shaft Troubleshooting

486

Propeller Shaft Components

487

Propeller Shaft Removal (2WD)

489

Propeller Shaft Removal (4WD)

489

Propeller Shaft Disassembly

491

Propeller Shaft Inspection Components

492

Spider Bearing Replacement

493

Propeller Shaft Assembly

498

Propeller Shaft Installation (2WD)

499

Propeller Shaft Installation (4WD)

500

Propeller Shaft Service Specifications

503

Propeller Shaft Torque Specifications

504

Suspension and Axle Troubleshooting

506

Wheel Alignment 4WD

507

Wheel Alignment 2WD

512

Front Axle Hub and Steering Knuckle Components

515

Front Axle Hub Disassembly, Inspection and Repair

516

Front Axle Hub Assembly

517

Steering Knuckle Removal and Inspection

519

Steering Knuckle Installation

520

Front Suspension Components

521

Ball Joint

522

Ball Joints Installation

523

Torsion Bar Spring

524

Lower Suspension Arm and Shock Absorber

526

Upper Suspension Arm

529

Upper Arm Bushing Replacement

529

Upper Suspension Arm Installation

530

Strut Bar

531

Stabilizer Bar

532

Free Wheeling Hub Components

533

Free Wheeling Hub Removal

534

Free Wheeling Hub Disassembly

534

Free Wheeling Hub Inspection

535

Free Wheeling Hub Assembly

535

Free Wheeling Hub Installation

537

Front Axle Hub and Steering Knuckle Components View

539

Steering Knuckle Removal

540

Steering Knuckle Inspection and Replacement

541

Front Drive Shaft Components

546

Front Drive Shaft Removal

546

Front Drive Shaft Disassembly

547

Front Drive Shaft Assembly

548

Front Drive Shaft Installation

551

Front Differential: On-Vehicle Replacement of Rear Oil Seal

553

Removal of Front Differential

557

Replacement of Side Oil Seal (Without A.D.D.)

559

Replacement of Side Oil Seal (with A.D.D.)

561

Replacement of RH Side Oil Seal

564

Disassembly and Assembly of Differential (Without A.D.D.)

566

Differential Disassembly

567

Differential Inspection and Replacement

570

Differential Assembly

574

Disassembly and Assembly of Differential (with A.D.D.)

582

LH Side Inspection and Replacement

591

Actuator Inspection and Replacement

593

Assembly of Differential

596

Installation of Front Differential

606

A.D.D. Control System Components

607

Electrical Circuit Diagram

608

Front Suspension Components View

611

Ball Joints Inspection

612

Ball Joints Removal

612

Torsion Bar Spring Removal

614

Torsion Bar Spring Installation

614

Lower Suspension Arm and Shock Absorber Removal

616

Lower Suspension Arm Bushing Placement

617

Shock Absorber Inspection

617

Lower Suspension Arm and Shock Absorber Installation

617

Upper Suspension Arm Removal

619

Stabilizer Bar Removal and Installation

622

Rear Axle Shaft (Single Tire) Components

623

Removal of Rear Axle Shaft

624

Rear Axle Shaft Components Inspection and Repair

624

Rear Axle Shaft Installation

626

Rear Axle Shaft and Axle Hub (Double Tire) View

627

Rear Axle Shaft Removal

627

Inspection of Rear Axle Shaft Components

628

Installation of Rear Axle Shaft

628

Disassembly of Rear Axle Hub

629

Rear Axle Hub Inspection and Repair

629

Rear Axle Hub Assembly

631

Differential Components View

634

Oil Seal On-Vehicle Replacement

635

Differential Removal

636

Replacement of Differential Case Component Parts

641

Installation of Differential

651

Rear Suspension Shock Absorber Components

653

Shock Absorber Removal

653

Shock Absorber Inspection (Rear)

654

Shock Absorber Disposal

654

Shock Absorber Installation

654

Leaf Spring Components

655

Leaf Spring Removal

657

Bushing Replacement

658

Stabilizer Bar Removal

662

Brake System Troubleshooting

665

Brake System Checks and Adjustments

669

Brake Booster Operational Test

670

Brake System Bleeding

671

Parking Brake Check and Adjustment

672

Removal of Master Cylinder

673

Disassembly of Master Cylinder

674

Inspection of Master Cylinder

675

Assembly of Master Cylinder

676

Installation of Master Cylinder

678

Brake Booster Removal

679

Brake Booster Installation

680

Front Brake 4WD (S12 + 12 Type Disc) Components

681

Brake Pads Replacement

681

Cylinder Removal

683

Cylinder Disassembly

684

Front Brake Components Inspection and Repair

685

Cylinder Assembly

686

Cylinder Installation

687

Rear Brake 4WD Components

688

Rear Drum Brake Removal

688

Rear Brake Components Inspection and Repair

691

Rear Brakes Assembly

692

Parking Brake Bellcrank Assembly and Installation

692

Load Sensing Proportioning and By-Pass Valve (LSP & BV) Components

697

Fluid Pressure Check and Adjustment

697

LSP & BV or LSPV Removal

700

LSP & BV or LSPV Assembly Disassembly

700

LSP & BV or LSPV Inspection

701

LSP & BV or LSPV Assembly

701

LSP & BV or LSPV Installation

702

Rear-Wheel Anti-Lock Brake System Description

703

Rear-Wheel Anti-Lock Brake System Wiring Diagram

704

Rear-Wheel Anti-Lock Brake System Connectors

705

Diagnosis System Inspection

706

Diagnostic Trouble Codes Table

708

Clearing of Diagnostic Trouble Codes

709

Rear–Wheel Anti–Lock Brake System Troubleshooting

711

«Rear Antilock» Warning Light Comes on

711

”REAR ANTILOCK” Warning Light Does Not Come on for 2 Seconds

713

«REAR ANTILOCK» Warning Light Comes on and off

714

Rear–Wheel Anti–Lock Brake System Works Inefficiently

716

Deceleration Sensor and Speed Sensor Diagnosis System Precaution

717

Diagnostic Trouble Code

719

Brake Actuator Components View

720

Brake Actuator Inspection

720

Brake Actuator Removal

723

Brake Actuator Installation

725

Rear-Wheel Anti-Lock Brake System Bleeding

727

Control Relay

728

Solenoid Relay Inspection

728

Speed Sensor Inspection

729

Speed Sensor and Sensor Rotor Serrations (Reference)

731

Deceleration Sensor Inspection

732

Rear–Wheel Anti–Lock Brake System Circuit

733

System Circuit Inspection

733

ECU Installation

734

Steering Troubleshooting

736

Steering On-Vehicle Inspection

737

Steering Wheel Freeplay Inspection

737

Oil Level Check

737

Steering Column Removal and Installation

738

Non–Tilt Steering Column Components View

739

Steering Column Disassembly

740

Non-Tilt Steering Column Inspection and Replacement

741

Non-Tilt Steering Column Assembly

742

Tilt Steering Column Components View

743

Disassembly of Steering Column

744

Inspection and Replacement of Steering Column

747

Assembly of Steering Column

748

Manual Gear Housing (2WD)

753

Manual Gear Housing Removal and Installation

753

Manual Gear Housing (2WD) Components View

754

Manual Gear Housing Disassembly

755

Manual Gear Housing Inspection and Replacement

755

Steering Gear Housing Assembly

757

Manual Gear Housing (4WD) Removal and Installation

760

Manual Gear Housing (4WD) Components View

761

Manual Gear Housing (4WD) Disassembly

762

Manual Gear Housing Inspection and Replacement (4WD)

764

Manual Gear Housing Assembly (4WD)

767

Power Steering Description

770

Neutral (Straight-Ahead) Position

770

Power Steering On-Vehicle Inspection

771

Vane Pump

771

Drive Belt Tension Check

772

Fluid Level Check

772

Power Steering Fluid Replacement

773

Power Steering Fluid Bleeding

774

Power Steering Pump Removal and Installation

777

VZN Series Power Steering Components

779

Power Steering Pump Disassembly

779

Power Steering Pump Inspection

782

Power Steering Pump Assembly

784

RN Series Power Steering Components

788

Gear Housing (2WD) Removal and Installation

797

Gear Housing (2WD) Components View

799

Gear Housing (2WD) Disassembly

800

Gear Housing Inspection and Replacement

802

Gear Housing Assembly

805

Gear Housing (4WD) Removal and Installation

807

Gear Housing (4WD) Components View

810

Gear Housing (4WD) Disassembly

811

Gear Housing (4WD) Inspection and Replacement

813

Gear Housing (4WD) Assembly

816

Progressive Power Steering (PPS)

819

Progressive Power Steering (PPS) Troubleshooting

820

Electronic Control System On-Vehicle Inspection

823

Check Solenoid Operation

823

Power Steering ECU Inspection

824

Removal and Installation of Steering Linkage (2WD)

825

Idler Arm Bracket Disassembly

827

Idler Arm Bracket Assembly

828

Steering Linkage (4WD) Removal and Installation

829

Body Electrical System

834

Body Electrical System — General Information

835

Replacement of High Current Fuse, Medium Current Fuse and Fuse

836

Check for Voltage

837

Check for Continuity and Resistance

837

Check the Bulb

838

Check for Short Circuit

838

Power Source Parts Location

839

Wiring Diagram

840

Ignition Switch Parts Location

841

Ignition System Parts Inspection

841

Key Confine Prevention System

842

Lighting System Parts Location

843

Lighting System Wiring and Connector Diagrams

844

Lighting System Troubleshooting

847

Adjustment of Light Aiming

849

Lighting System Parts Replacement

849

Disassembly of Combination Switch

850

Assembly of Combination Switch

851

Headlight, Taillight and Daytime Running Light System Parts Inspection

852

Lights–On Warning System

855

Illuminated Entry System

855

Turn Signal and Hazard Warning System

856

Wiper and Washer System Parts Location

857

Wiper and Washer System Troubleshooting

858

Wiper and Washer System Parts Inspection

859

Washer System Inspection

861

Combination Meter Parts Location

862

Meter Circuit

863

Combination Meter Troubleshooting

865

Speedometer System Inspection

866

Tachometer System Inspection

866

Fuel Gauge System Inspection

867

Fuel Level Warning System Inspection

868

Engine Coolant Temperature Gauge System Inspection

869

Low Oil Pressure Warning System Inspection

870

Brake Warning System Inspection

871

Seat Belt Warning System Inspection

873

Illumination Control System Inspection

875

Power Window Control System

876

Power Window Control System Troubleshooting

877

Power Window Control System Parts Inspection

877

Power Door Lock Control System

881

Power Door Lock Control System Troubleshooting

882

Power Door Lock Control System Parts Inspection

882

Door Lock Signal

884

Key–Off Power Window Signal

885

Power Mirror Control System

886

Power Mirror Control System Troubleshooting

887

Power Mirror Control System Parts Inspection

887

Cruise Control System Parts Location

889

Cruise Control System Wiring Diagram

891

Cruise Control System Connector Diagrams

892

Cruise Control System Description

893

Cruise Control System: Output of Diagnostic Trouble Code

894

Cruise Control System Troubleshooting

896

Cruise Control System Inspection Chart

897

Power Source Circuit Inspection

897

Cruise Control Switch Circuit Inspection

901

Actuator Circuit Inspection

902

Speed Sensor Circuit Inspection

904

Stop Light Switch Circuit Inspection

905

Parking Brake Switch Circuit Inspection

906

Clutch Switch Circuit Inspection

907

Park/Neutral Position Switch Circuit Inspection

908

Vacuum Circuit Inspection

909

ECM Solenoid Circuit Inspection

911

Cruise Control ECU Circuit

912

Inspection of ECU Circuit

912

Switches Inspection

913

Audio System Parts Location

916

Audio System Wiring and Connector Diagrams

917

Audio System Description

921

Tape Player Maintenance

922

Anti–Theft System

922

Audio System: How to Use Diagnostic Chart

923

Audio System Troubleshooting

924

Anti-Theft System Troubleshooting

925

Radio: no Power Coming in

926

Power Coming In, but Radio Not Operating

927

Noise Present, but AM-FM Not Operating

927

Either Speaker Does Not Work

928

Either AM/FM Does Not Work, Reception Poor, few Preset Tuning Bands

929

Sound Quality Poor

930

Cannot Set Station Select Button, Preset Memory Disappears

931

Tape Player: Cassette Tape Cannot be Inserted

932

Cassette Tape Inserts, but no Power

933

Power Coming In, but Tape Player Not Operating

934

Tape Player: Either Speaker Does Not Work

935

Tape Player: Sound Quality Poor (Volume Faint)

936

Tape Jammed, Malfunction with Tape Speed or Auto-Reverse

936

APS, Skip, RPT Buttons Not Operating

937

Cassette Tape will Not Eject

937

Antenna Troubleshooting

938

Noise Produced by Vibration or Shock While Dirving

939

Noise Produced When Engine Starts

940

Audio System Parts Inspection

941

Antenna Motor Inspection

941

Antenna Motor Control Relay Inspection

941

Antenna Rod Removal and Installation

942

Clock Troubleshooting

943

Body — General Information

945

Hood Adjustment

946

Front Door Components View

947

Front Door Adjustment

949

Front Door Disassembly

949

Glass Replacement

952

Front Door Assembly

952

Windshield Moulding Components View

956

Windshield Moulding Removal

956

Fastener Replacement

957

Windshield Moulding Installation

958

Wheel Arch Moulding Components

959

Front Wheel Arch Moulding Replacement

959

Rear Wheel Arch Moulding Replacement

959

Windshield (Adhesive Type)

960

Windshield Removal

961

Preparation for Windshield Installation

962

Windshield Installation

963

Back Window Components

965

Back Window Removal

965

Back Window Assembly Disassembly and Assembly

966

Back Window Installation

967

Quarter Window (Xtra Cab) Components

968

Quarter Window Removal

968

Quarter Window Installation

969

Moon Roof Components View

970

Moon Roof Removal

971

Moon Roof Installation

972

Removable Roof Disassembly

974

Removable Roof Assembly

974

Instrument Panel Components

975

Instrument Panel Removal

977

Instrument Panel Installation

981

One-Touch Tail Gate Components

982

Removal of Tail Gate Lock

982

Tale Gate Lock Installation

983

Tail Gate Lock Control Removal and Installation

983

Front Seat Components

984

Rear Jump Seat Components

985

Front Seat Belt Components

986

Rear Jump Seat Belt Components

987

Emergency Locking Retractor (ELR) Type Seat Belt Testing

988

Center Seat Belt (Manual Type) Testing

988

Body Dimensions

989

Frame Dimensions

992

Air Conditioning System

1006

Air Conditioning System — General Information

1007

Refrigeration System

1007

Handling Precautions for Refrigerant

1008

Handling Precautions for Gas–Cylinder Type Gas Leak Tester

1009

Precautions When Replacing Parts in Refrigerant Line

1009

Precautions When Charging Refrigerant

1010

Air Conditioning System Circuit

1011

Air Conditioning System Components View

1012

Refrigeration Cycle

1013

Principle of A/C Electrical Circuit

1014

How Is Magnetic Clutch Energized?

1014

Air Conditioning System Troubleshooting

1015

Inspection of Refrigeration System with Manifold Gauge Set

1017

Air Conditioning System On-Vehicle Inspection

1020

Checking of Refrigerant Volume

1021

Installation of Manifold Gauge Set

1021

Compressor On-Vehicle Inspection

1022

Compressor Removal

1023

Magnetic Clutch Disassembly

1024

Magnetic Clutch Assembly

1026

Compressor Installation

1027

Receiver On-Vehicle Inspection

1028

Receiver Removal and Installation

1028

Condenser On-Vehicle Inspection

1029

Condenser Removal and Installation

1029

Cooling Unit Removal

1030

Expansion Valve On-Vehicle Inspection

1030

Cooling Unit Disassembly

1031

Evaporator Inspection

1032

Cooling Unit Assembly

1032

Cooling Unit Installation

1032

Refrigerant Lines On-Vehicle Inspection

1033

Refrigerant Lines Replacement

1033

AC Switch On-Vehicle Inspection

1034

Dual Pressure Switch Inspection

1034

Thermistor Inspection

1035

Thermistor Removal and Installation

1035

A/C Cut off Relay Inspection

1035

Air Conditioning Amplifier

1036

Vacuum Hose Circuit

1037

Vacuum Switching Valve (VSV) Inspection

1037

Heater Parts Location

1039

Heater Troubleshooting

1040

Damper Positions

1040

Heater Inspection and Adjustment

1041

Heater Parts Inspection

1042

Service Specifications

1044

22R–E Engine Starting System Data

1044

22R–E Engine Charging System Data

1044

3VZ–E Engine Data

1045

Clutch Specifications

1047

Manual Transmission Specifications

1047

Automatic Transmission Specifications

1055

Transfer Specifications

1061

Propeller Shaft Specifications

1065

Suspensoin and Axle Specifications

1066

Brake System Specifications

1073

Steering Specifications

1075

Body — Torque Specifications

1078

Lubricant Data

1079

-

Откуда: Караганда

-

Машина: 2008 T4R V6 4WD

AZIAT

3 645

-

Откуда: Сочи Красная Поляна

-

Машина: УАЗ Василий и LX570

yiri57

1

-

Откуда: Алтайский край

-

Машина: Toyota Hilux 2KD

maxikon

0

-

Откуда: ЧАО

-

Машина: 4Runer SR5 2003 г

maxikon

0

-

Откуда: ЧАО

-

Машина: 4Runer SR5 2003 г

Гитавод

0

-

Откуда: Питер

-

Машина: 4runner 4.0 2005 LTD

maxikon

0

-

Откуда: ЧАО

-

Машина: 4Runer SR5 2003 г

maxikon

0

-

Откуда: ЧАО

-

Машина: 4Runer SR5 2003 г

odmin4eg

5

-

Откуда: Красноряск

-

Машина: Toyota 4Runner 215 ’04 SE

VintFR

2

-

Откуда: Пермь, Питер, Париж, Монреаль

-

Машина: 215-й 4RUNNER 4,7 +JGC 5,7 Overland 2008года

Oleg71

9

-

Откуда: Якутия

-

Машина: 4runner 1GR-FE

Игорь О

0

-

Откуда: Омск

-

Машина: 4 RUNNER 215 SR5

Присоединяйтесь к обсуждению

Вы можете опубликовать сообщение сейчас, а зарегистрироваться позже.

Если у вас есть аккаунт, войдите в него для написания от своего имени.