-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

Related Manuals for Inovance MD380 Series

Summary of Contents for Inovance MD380 Series

-

Page 1

efesotomasyon.com… -

Page 2: Preface

This manual describes the correct use of the MD380 series AC drive, including selection, parameter setting, commissioning, maintenance & inspection. Read and understand the manual before use and forward the manual to the end user.

-

Page 3: Introduction

Advanced background software The background monitoring software helps to achieve functions of parameter upload & download and a real-time oscilloscope. Other new functions The newly added functions of the MD380 series AC drive are described as below: unction Description Virtual I/O It can implement various simple logic functions.

-

Page 4

MD380 User Manual Introduction unction Description our motors can be switched over via four groups of Multi-motor switchover motor parameters. It allows you to save or restore the parameters set by Restoring user parameters yourself. The AI/AO accuracy can reach almost 20 mv via factory Higher-accuracy AI/AO correction or on-site correction. -

Page 5

CE Mark The CE mark on the MD380 declares that the AC drive complies with the European low voltage directive (LVD) and EMC directive. The MD380 series AC drive complies with the following LVD and EMC directives and standards: Directive… -

Page 6: Table Of Contents

Contents Preface ……………………1 Introduction ………………….2 Chapter 1 Safety Information and Precautions………… 10 1.1 Safety Information ………………….10 1.2 General Precautions …………………. 12 Chapter 2 Product Information …………….18 2.1 Designation Rules and Nameplate of the MD380 …………18 2.2 Components of the MD380………………..

-

Page 7

4.17 Password Setting………………….77 4.18 Parameter Saving and Default Setting Restoring …………77 Chapter 5 unction Code Table …………….80 5.1 Standard unction Parameters………………80 5.2 Monitoring Parameters ………………..133 Chapter 6 Description of unction Codes…………136 Group 0: asic Parameters ………………… 136 Group 1: Motor 1 Parameters……………… -

Page 8

Chapter 7 EMC ………………..248 7.1 De nition of Terms ………………….. 248 7.2 Introduction to EMC Standard ………………248 7.3 Selection of Peripheral EMC Devices…………….249 7.4 Shielded Cable ………………….256 7.5 Solutions to Common EMC Interference Problems …………. 258 Chapter 8 Selection and Dimensions ………….. -

Page 9

efesotomasyon.com… -

Page 10

Safety Information and Precautions efesotomasyon.com… -

Page 11: Chapter 1 Safety Information And Precautions

Read this manual carefully so that you have a thorough understanding. Installation, commissioning or maintenance may be performed in conjunction with this chapter. Inovance will assume no liability or responsibility for any injury or loss caused by improper operation.

-

Page 12

MD380 User Manual Safety Information and Precautions Safety Use Stage Precautions Grade Wiring must be performed only by quali ed personnel under instructions described in this manual. ailure to comply may result in unexpected accidents. A circuit breaker must be used to isolate the power supply and the AC drive. -

Page 13: General Precautions

Safety Information and Precautions MD380 User Manual Safety Use Stage Precautions Grade Do not touch the fan or the discharging resistor to check the temperature. ailure to comply will result in personal burnt. Signal detection must be performed only by quali ed personnel DANGER during operation.

-

Page 14

MD380 User Manual Safety Information and Precautions Motor insulation test Perform the insulation test when the motor is used for the first time, or when it is reused after being stored for a long time, or in a regular check-up, in order to prevent the poor insulation of motor windings from damaging the AC drive. -

Page 15

Safety Information and Precautions MD380 User Manual Voltage-sensitive device or capacitor on output side of the AC drive Do not install the capacitor for improving power factor or lightning protection voltage- sensitive resistor on the output side of the AC drive because the output of the AC drive is PWM wave. -

Page 16

13) Altitude and de-rating In places where the altitude is above 1000 m and the cooling effect reduces due to thin air, it is necessary to de-rate the AC drive. Contact Inovance for technical support. 14) Some special usages If wiring that is not described in this manual such as common DC bus is applied, contact the agent or Inovance for technical support. -

Page 17

Safety Information and Precautions MD380 User Manual efesotomasyon.com — 16 -… -

Page 18

Product Information efesotomasyon.com… -

Page 19: Chapter 2 Product Information

Rated output S/N: 010150602803825403 Manufacturing SN Shenzhen Inovance Technology Co.,Ltd. 2.2 Components of the MD380 The MD380 series AC drives have two housing types, plastic housing and sheet metal housing, according to different voltage and power classes. efesotomasyon.com — 18 -…

-

Page 20

MD380 User Manual Product Information Inovance logo Operation panel Control terminals Power terminals Interface for connecting external operation panel cover Cabling board AC drive nameplate Inovance logo Operation panel Control board Power cover terminals AC drive nameplate Grommet efesotomasyon.com — 19 -… -

Page 21: Technical Speci Cations

Product Information MD380 User Manual The housing types of the MD380 models with different voltage and power classes are listed in the following table. Table 2-1 Housing types for different voltage and power classes Voltage & Power Class Housing Type Single-phase 220 V 0.4–2.2 kW Plastic housing…

-

Page 22

MD380 User Manual Product Information Item G type: 60s for 150% of the rated current, 3s for 180% of the rated current Overload capacity P type: 60s for 120% of the rated current, 3s for 150% of the rated current ixed boost Torque boost Customized boost 0.1%–30.0%… -

Page 23

The optional programming card helps you to realize secondary development. Its programming environment is programmable function compatible with that of the PLC of Inovance. Advanced It supports the operation of AC drive parameters and virtual background oscillograph function, via which the state inside the AC drive software is monitored. -

Page 24

MD380 User Manual Product Information Item Standard 1 high-speed pulse output terminal (open-collector) that supports 0–100 kHz square wave signal output 1 digital output (DO) terminal 1 relay output terminal 1 analog output (AO) terminal that supports 0–20 mA Output terminal current output or 0–10 V voltage output Expanding capacity: 1 DO terminal… -

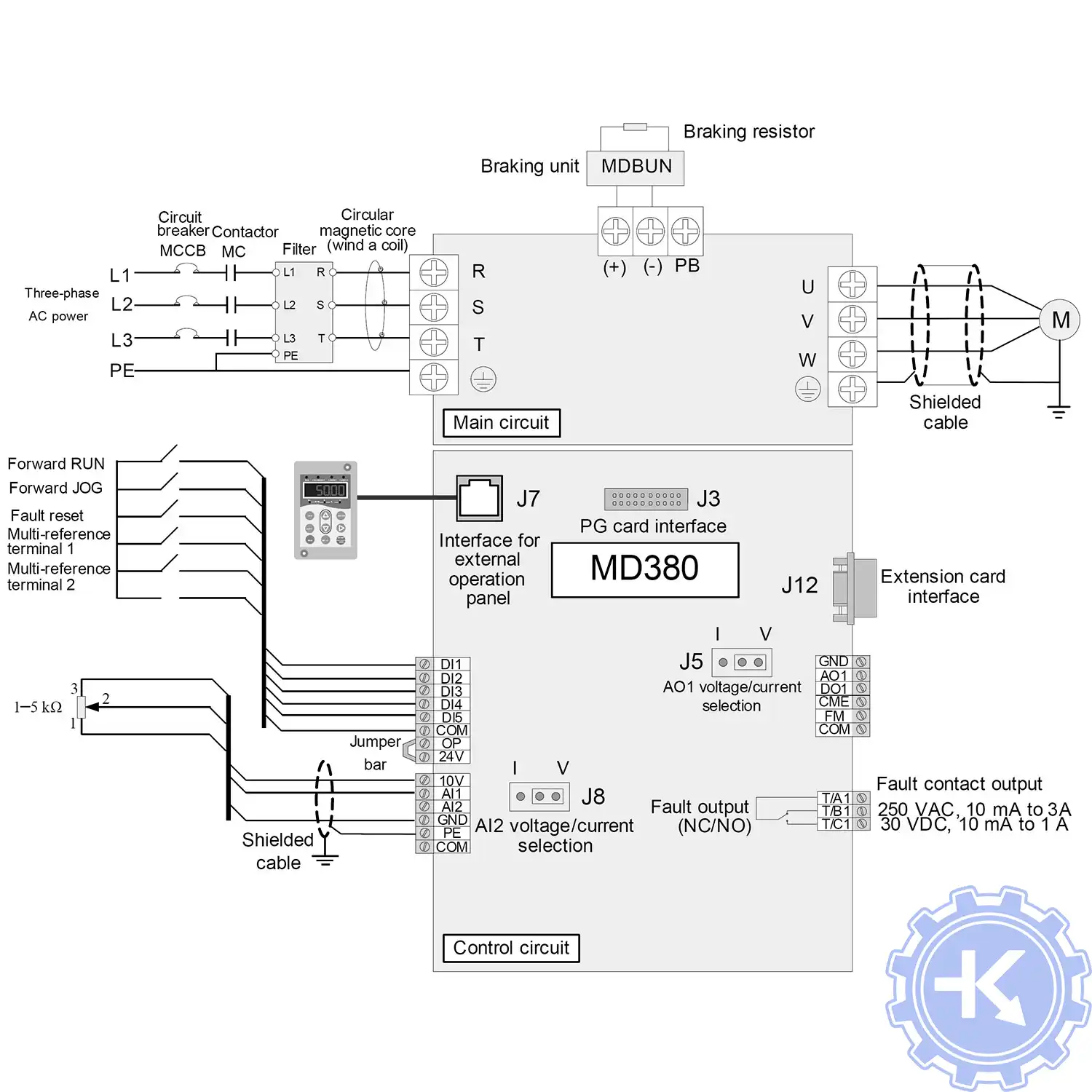

Page 25: Peripheral Electrical Devices And System Con Guration

Product Information MD380 User Manual 2.4 Peripheral Electrical Devices and System Con guration When the MD380 is used to control the synchronous or asynchronous motor, forming a control system, it is necessary to install various electrical devices on the input and output sides of the AC drive to ensure the system safety and stability.

-

Page 26

MD380 User Manual Product Information 2.4.1 Description of Peripheral Electrical Devices Table 2-3 Description of peripheral electrical devices Part Mounting Location unction Description Interrupt the power supply when overcurrent occurs on Power receiving side downstream devices Start and stop the AC drive. etween MCC and Do not start and stop the AC drive frequently by switching Contactor… -

Page 27

It is the Pro bus-DP communication It applies to the models MD38DP communication card. of 3.7 kW and above. card User It is compatible to Inovance’s H1U It applies to the models MD38PC1 programmable series PLC. of 3.7 kW and above. card efesotomasyon.com… -

Page 28

MD380 User Manual Product Information Name Model unction Remark Differential It is the differential resolver interface card. encoder MD38PG1 It applies to all models. It is adaptable to 5 V power supply interface card It is suitable for the UVW differential encoder and applied to synchronous UVW encoder MD38PG3… -

Page 29

Product Information MD380 User Manual efesotomasyon.com — 28 -… -

Page 30

Mechanical and Electrical Installation efesotomasyon.com… -

Page 31: Chapter 3 Mechanical And Electrical Installation

Vibration ar away from the punching machine or the like The MD380 series AC drives of plastic housing are the whole unit built-in products operated through remote control and need to be installed in the nal system.The nal system must have the required…

-

Page 32

MD380 User Manual Mechanical and Electrical Installation The MD380 series AC drive dissipates heat from the bottom to the top. When multiple AC drives are required to work together, install them side by side. above another row, install an insulation guide plate to prevent AC drives in the lower row from heating those in the upper row and causing faults. -

Page 33

Mechanical and Electrical Installation MD380 User Manual Embedded installation of the MD380 (plastic housing) External hanging bracket Install the AC drive on the front of the control cabinet . control cabinet efesotomasyon.com — 32 -… -

Page 34

MD380 User Manual Mechanical and Electrical Installation Wall-mounting installation of the MD380 (sheet metal housing) Install the AC drive on the front of the control cabinet . control cabinet Embedded installation of the MD380 (sheet metal housing) External hanging bracket efesotomasyon.com — 33 -… -

Page 35

Mechanical and Electrical Installation MD380 User Manual Install the AC drive from the back of the control cabinet . control cabinet Installation Precautions Reserve the installation clearances as specified in igure 3-1 to ensure sufficient space for heat dissipation. Take heat dissipation of other parts in the cabinet into consideration. -

Page 36: Electrical Installation

MD380 User Manual Mechanical and Electrical Installation 3.1.4 Removal of the ront Cover of the MD380 main circuit and control circuit. 2. Catch the edge of the cover and lift it. 1. Press inward symmetrically to disconnect the hook Hook slot from the hook slot.

-

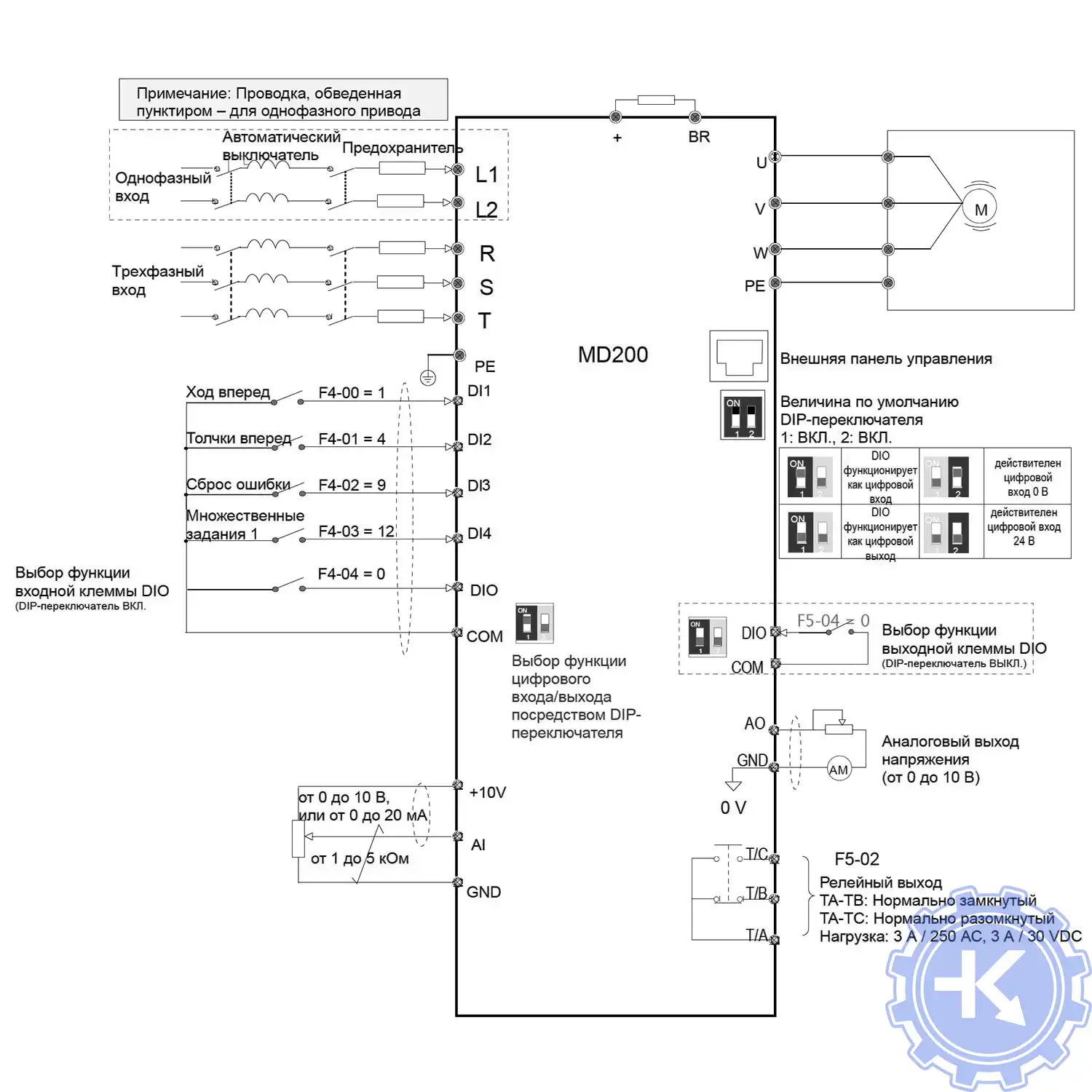

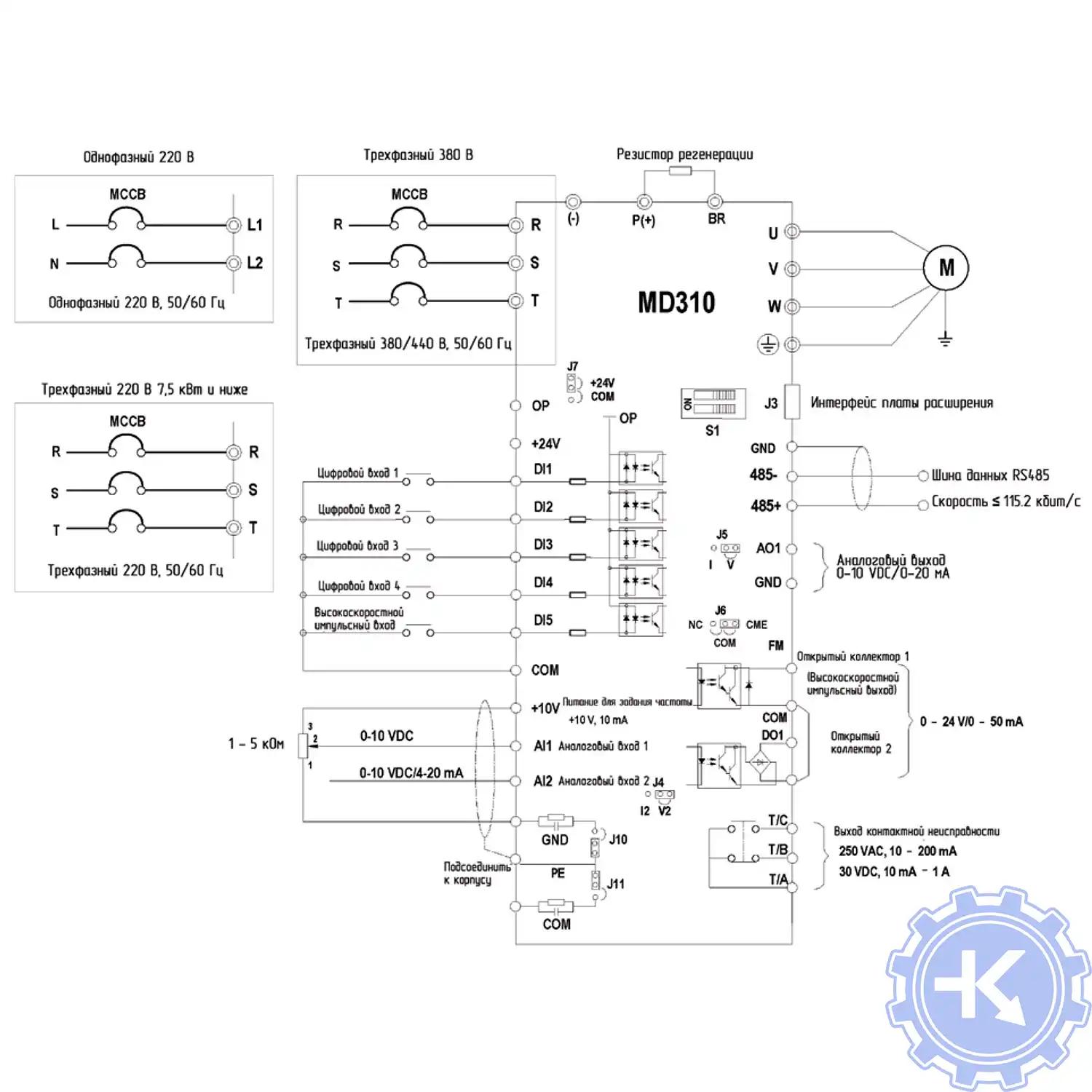

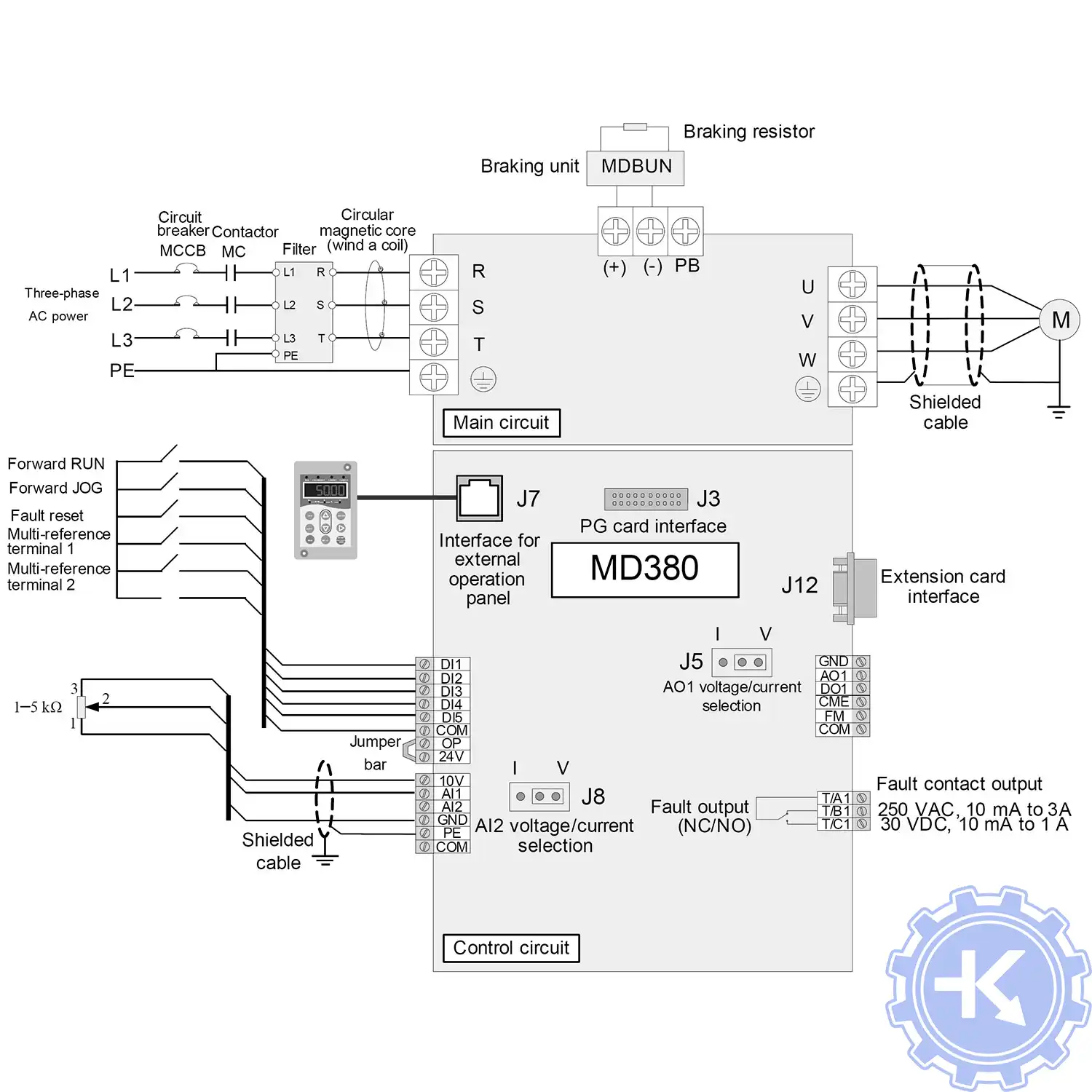

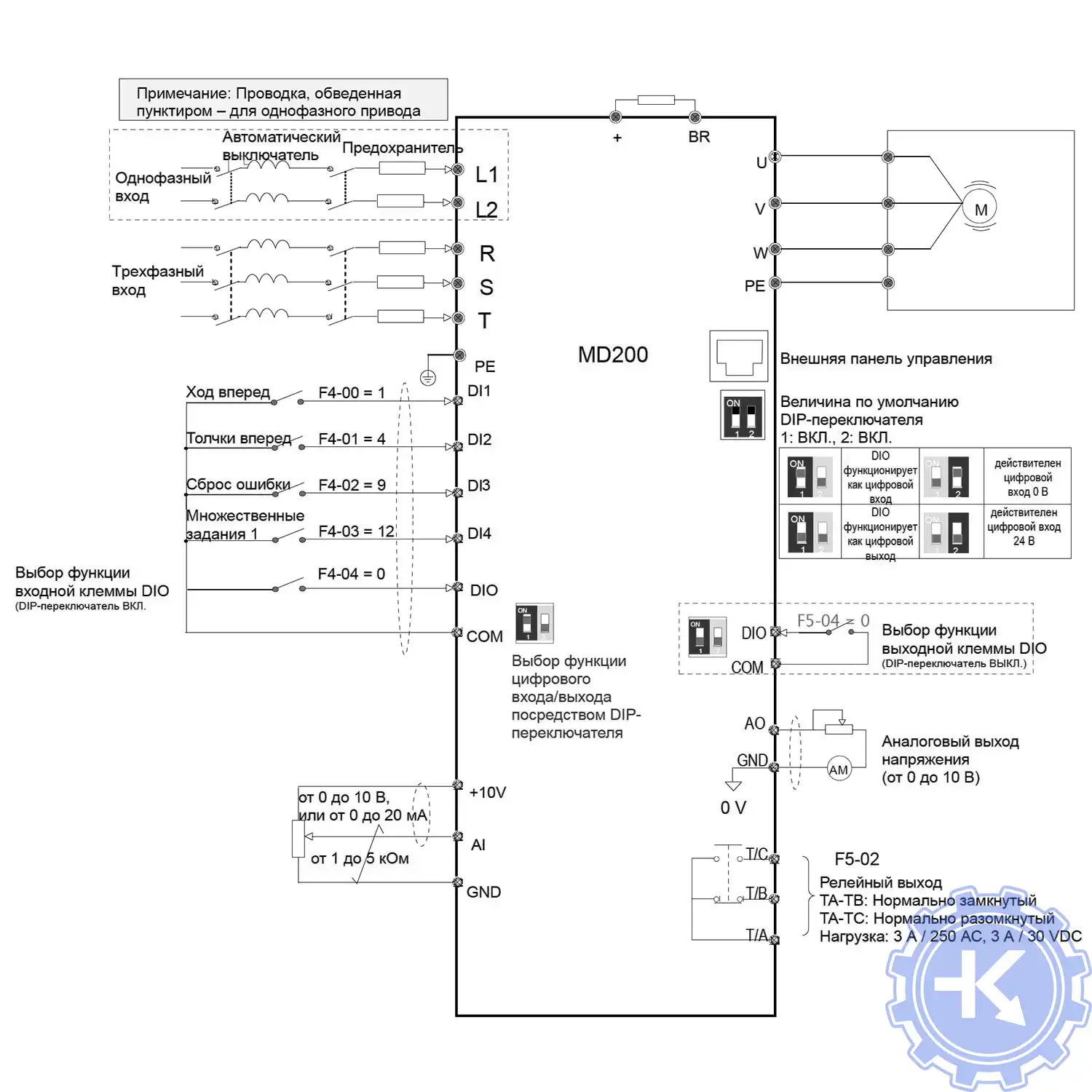

Page 37

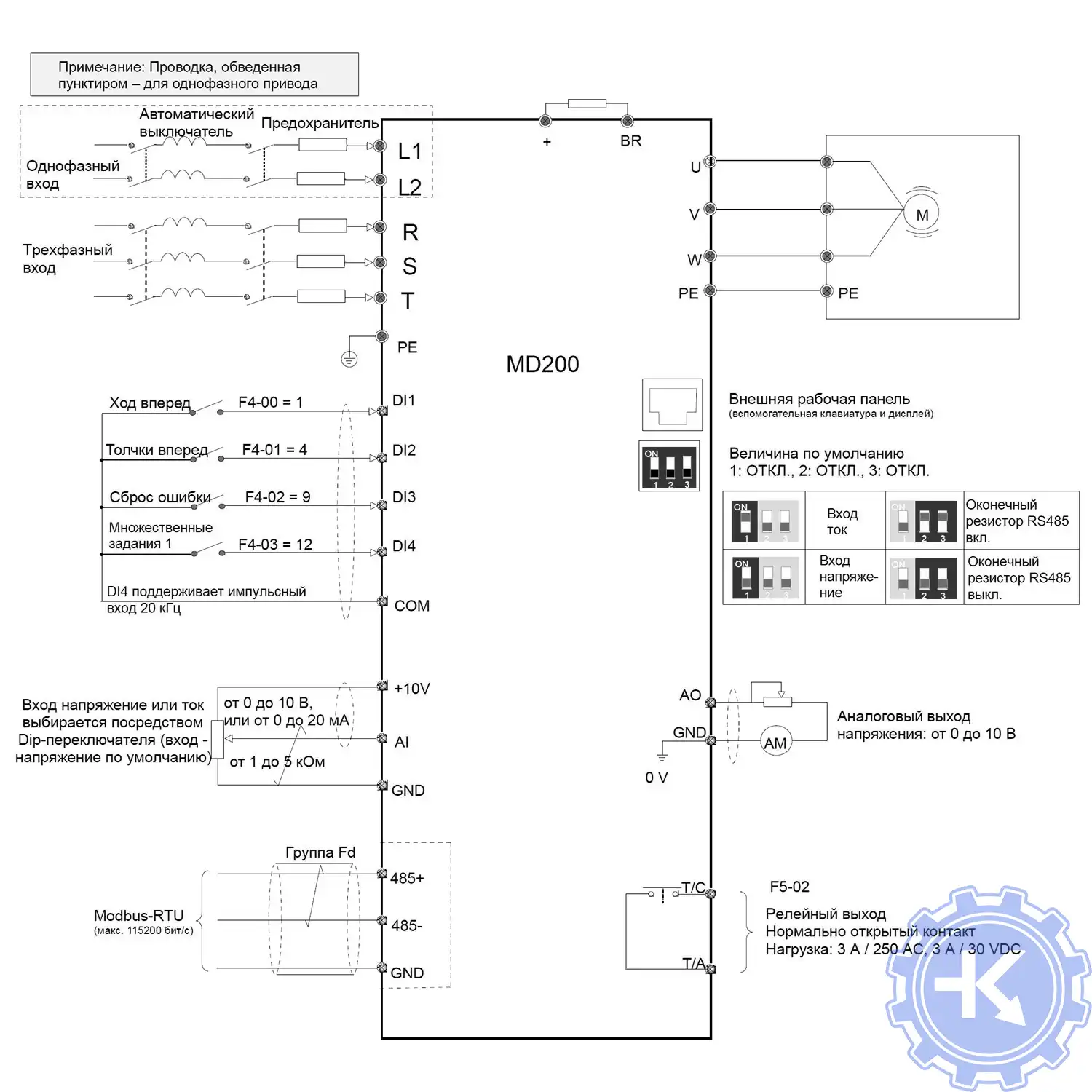

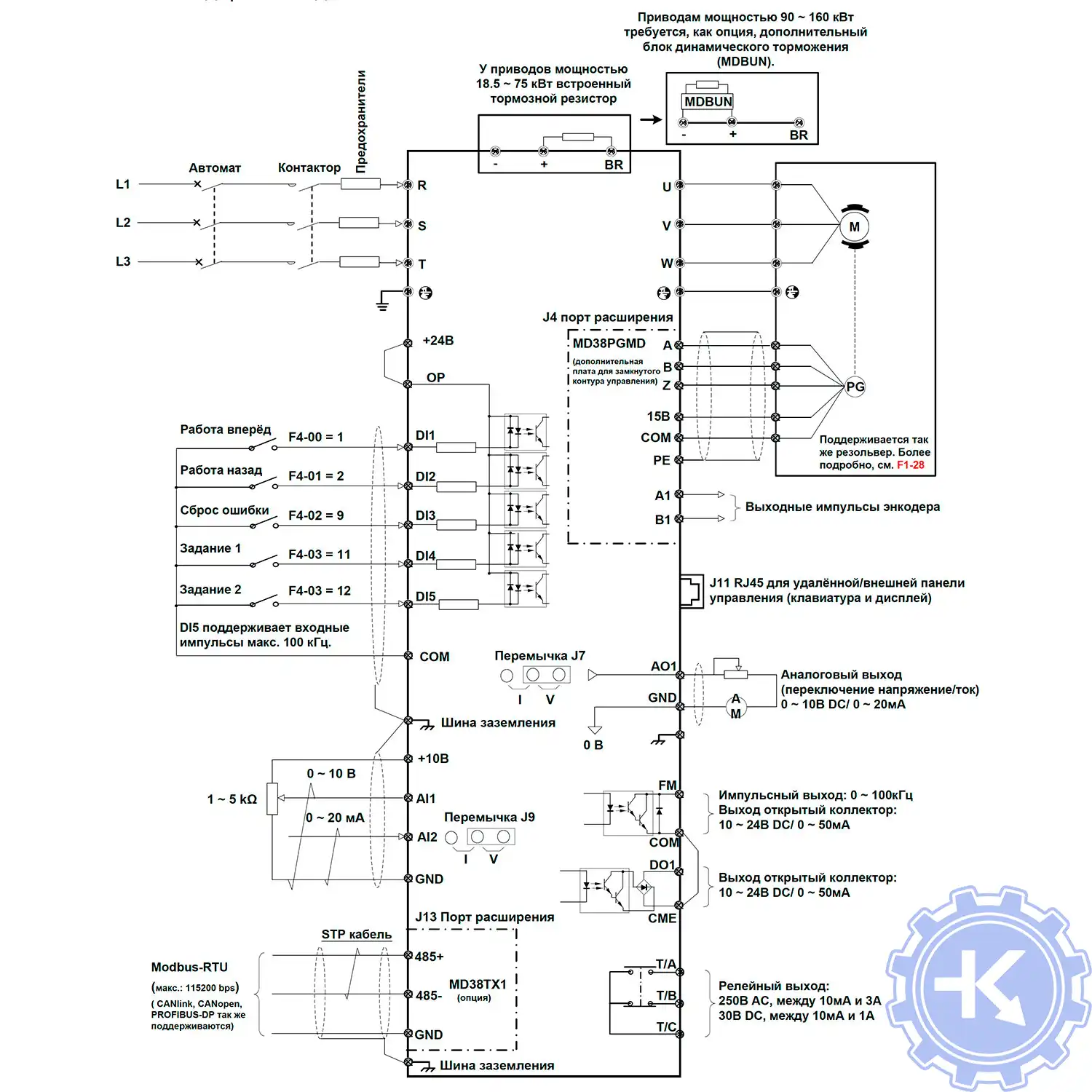

Mechanical and Electrical Installation MD380 User Manual Table 3-1 Description of main circuit terminals of single-phase AC drive Terminal Name Description Single-phase power supply Connect to the single-phase 220 VAC power L1, L2 input terminals supply. Positive and negative (+), (-) Common DC bus input point. -

Page 38

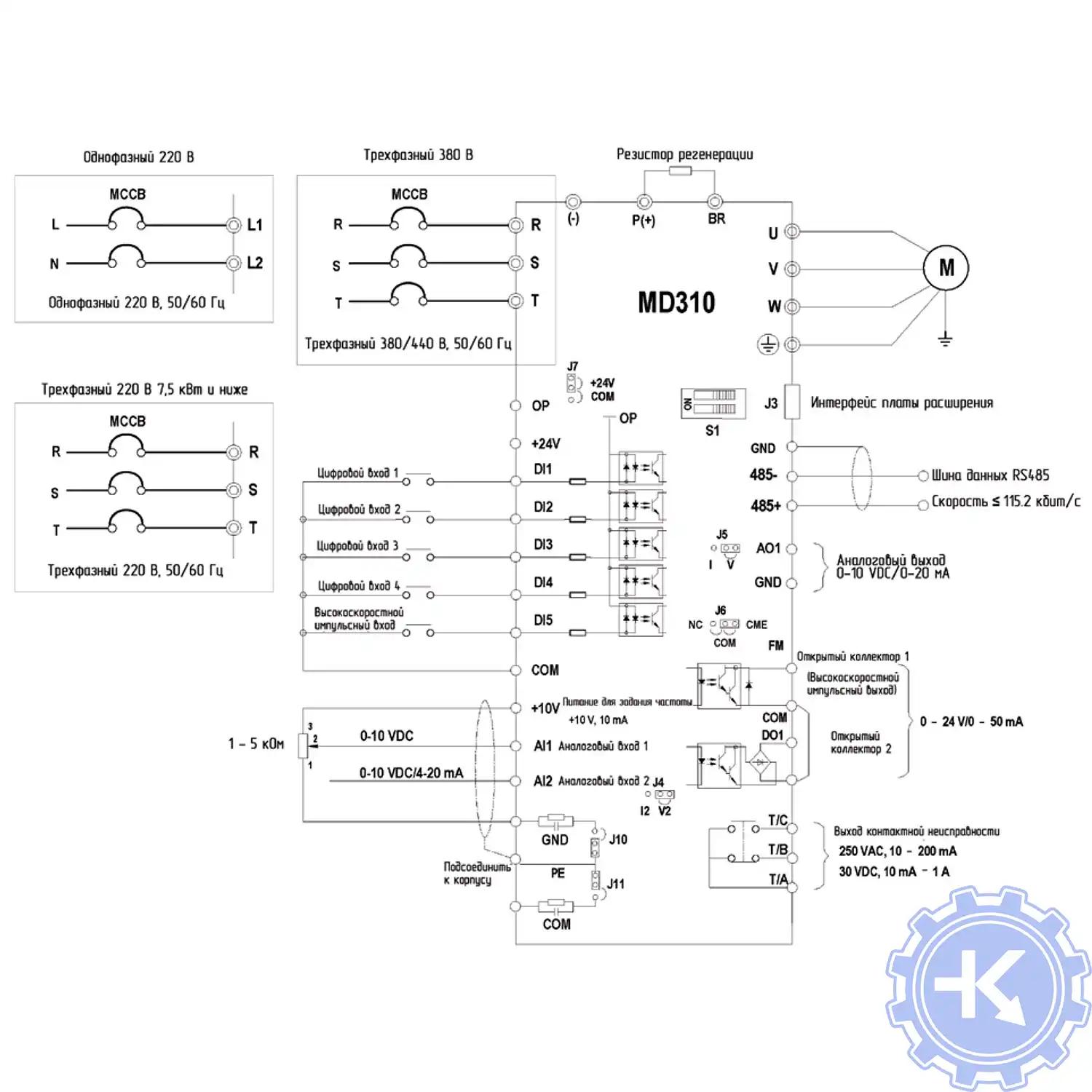

MD380 User Manual Mechanical and Electrical Installation 3.2.2 Wiring of AC Drive Main Circuit Table 3-3 Wiring of the AC drive main circuit Single-phase 220 V Three-phase 220 V (15 kW and elow) Single-phase (–) (–) 220 V Three -phase 220 V 50/60 Hz 50/60 Hz… -

Page 39

Mechanical and Electrical Installation MD380 User Manual Precautions on the Wiring Power input terminals L1, L2 or R, S, T – The cable connection on the input side of the AC drive has no phase sequence requirement. – with the local safety regulations and related IEC standards. –… -

Page 40

MD380 User Manual Mechanical and Electrical Installation – Do not connect the earthing terminal to the neutral conductor of the power supply. – The impedance of the PE conductor must be able to withstand the large short- circuit current that may arise when a fault occurs. –… -

Page 41

Mechanical and Electrical Installation MD380 User Manual Type Terminal Name Input voltage range: 0–10 VDC AI1-GND Analog input 1 Input range: 0–10 VDC/4–20 mA, decided by jumper J8 on the control board AI2-GND Analog input 2 input) DI1- OP Digital input 1 Optical coupling isolation, compatible with dual polarity input DI2- OP… -

Page 42

30 VDC 10 mA to 1 A (connect to the house) Note All MD380 series AC drives have the same wiring mode. The gure here shows the wiring of single-phase 220 VAC drive. indicates main circuit terminal, while indicates control circuit terminal. -

Page 43

Mechanical and Electrical Installation MD380 User Manual In applications where the analog signal suffers severe interference, install filter capacitor or ferrite magnetic core at the analog signal source. Cross or wind two or three coils in the same direction MD380 0.022 , 50 V magnetic core… -

Page 44

MD380 User Manual Mechanical and Electrical Installation Control board +24V +24V +VCC of AC drive 1 Signal 2.4k Control board +24V of AC drive 2 2.4k External controller b. SOURCE wiring In such wiring mode, remove the jumper between +24 V and OP. Connect +24 V to the common port of external controller and meanwhile connect OP to COM. -

Page 45

Mechanical and Electrical Installation MD380 User Manual Wiring of DO terminal When the digital output terminal needs to drive the relay, an absorption diode shall be installed between two sides of the relay coil. Otherwise, it may cause damage to the 24 VDC power supply. -

Page 46

Operation, Display and Application Examples efesotomasyon.com… -

Page 47: Chapter 4 Operation, Display And Application Examples

Operation, Display and Application Examples MD380 User Manual Chapter 4 Operation, Display and Application Examples 4.1 Operation Panel You can modify the parameters, monitor the working status and start or stop the MD380 by /Reverse Command rotation indicator source indicator ON: reverse rotation ON: local control (Local) : forward rotation…

-

Page 48

MD380 User Manual Operation, Display and Application Example TUNE/TC When the indicator is ON, it indicates torque control mode. When the indicator is blinking slowly, it indicates the auto-tuning state. When the indicator is blinking quickly, it indicates the fault state. Unit Indicators means that the indicator is ON, and Hz: unit of frequency… -

Page 49: Viewing And Modifying Unction Codes

Operation, Display and Application Examples MD380 User Manual Name unction Stop the AC drive when it is in the running state and perform the STOP Stop/Reset reset operation when it is in the fault state. The functions of this key are restricted in 7-02. Perform function switchover (such as quick switchover of Multifunction MF.K…

-

Page 50: Structure Of Unction Codes

MD380 User Manual Operation, Display and Application Example In Level III menu, if the parameter has no blinking digit, it means that the parameter cannot Such a function code is only readable, such as, AC drive model, actually detected parameter and running record parameter. at stop.

-

Page 51: Quick View Of Unction Codes

Operation, Display and Application Examples MD380 User Manual unction Parameter Name Setting Range Default Code Unit’s digit (group U display selection) 0: Not display 1: Display AC drive parameter P-02 display property Ten’s digit (group A display selection) 0: Not display 1: Display 4.4 Quick View of unction Codes The MD380 provides two quick modes of viewing the required function codes.

-

Page 52

MD380 User Manual Operation, Display and Application Example displayed. unction Code Parameter Name Setting Range Default -USEr Unit’s digit: group display selection 0: Not display Individualized 1: Display P-03 parameter display property —C— Ten’s digit: group display selection 0: Not display 1: Display -bASE -bASE… -

Page 53: De Nition And Operation Of The Multifunction Key (M .K)

Operation, Display and Application Examples MD380 User Manual 4.5 De nition and Operation of the Multifunction Key (M .K) 4.6 Viewing Status Parameters In the stop or running state, you can press on the operation panel to display status parameters. Whether parameters are displayed is determined by the binary bits of values In stop state, a total of 13 status parameters can be displayed, as listed in the following table.

-

Page 54

MD380 User Manual Operation, Display and Application Example In running state, five running status parameters are displayed by default, and you can following table. unction Parameter Setting Range Default Code Name 7 6 5 4 3 2 Running frequency 1 (Hz) Set frequency (Hz) Output voltage (V) Output current (A) -

Page 55: Starting Or Stopping The Ac Drive

Operation, Display and Application Examples MD380 User Manual When the AC drive is powered on again after power failure, the parameters that are selected before power failure are displayed. Select the required parameters by pressing . Set the values of the parameters by referring to the following example.

-

Page 56

MD380 User Manual Operation, Display and Application Example Example 1: To use the DIP switch as the start/stop source, and allocate the forward rotation switch signal to DI2 and the reverse rotation switch signal to DI3, perform the setting as shown Command source Setting selection… -

Page 57

Operation, Display and Application Examples MD380 User Manual 2: Communication control CANlink, and CANopen. The MD380 interacts with the user programmable card also by means of communication. 02 to 2. Then, you can start or stop the AC drive in communication mode. The following Command source Setting selection… -

Page 58

MD380 User Manual Operation, Display and Application Example 0-12 0-12 6-00 = 0 (Direct start) upper limit ) 6-00 = 0 (Direct start) 6-07 upper limit) (Acceleration / Deceleration mode ) Default: 6-06 = 0.0s 6-03 = 0.00 Hz 0-17 6-04 6-04 = 0.0s 0-17… -

Page 59

Operation, Display and Application Examples MD380 User Manual 4.7.3 Stop Mode 6-10 = 1: Coast to stop Running frequency Running 6-10 = 0: Decelerate to stop frequency Rotational speed under 0-18 load , coast to stop by (Deceleration time) inertia 6-12 (Waiting time of stop DC braking) -

Page 60

MD380 User Manual Operation, Display and Application Example 4.7.5 JOG Running In certain applications, the AC drive needs to run in low speed temporarily to facilitate equipment test or other commissioning operations. In this case, you can set the AC drive to perform JOG running. -

Page 61: Setting The Running Requency

Operation, Display and Application Examples MD380 User Manual Parameter Setting and Operation of JOG Running in DI Terminal Control is more convenient to control JOG running by using keys or buttons. To achieve Setting Terminal Parameter setting Terminal JOG control value value button…

-

Page 62

MD380 User Manual Operation, Display and Application Example According to the preceding figure, the running frequency of the AC drive can be set by means of function codes, manual adjustment, analog input, multi-speed terminal, external feedback signal, internal PID regulator, or the host computer. Set the corresponding function codes of each frequency setting mode, as shown in the 4.8.2 requency Setting by the Auxiliary requency Source The frequency setting by the auxiliary frequency source is the same as the frequency setting… -

Page 63

Operation, Display and Application Examples MD380 User Manual indicates the default setting. frequency sources Target running source source to frequency operation switchover frequency selection source 0-07 (unit ‘s digit) Main 0-27 (default value: 000) Hundred’s digit Ten’s digit Unit’s digit frequency (Communication) (Terminal) -

Page 64

MD380 User Manual Operation, Display and Application Example 4.8.4 AI as the requency Source The AI terminal can be used as the frequency source. The MD380 provides two AI terminals (AI1 and AI2) on the control board, and the optional I/O extension card provides another AI terminal (AI3). -

Page 65

Operation, Display and Application Examples MD380 User Manual 4.8.5 Pulse Setting as the requency Source signals are: voltage 9–30 V, frequency 0–100 kHz. Only DI5 can be used for pulse input. The relationship between pulse input from DI5 and Setting Terminal code value… -

Page 66

MD380 User Manual Operation, Display and Application Example 4.8.7 Swing Mode Swing frequency running With swing Without swing -01 0% frequency frequency -02: Jump frequency amplitude -03: Swing frequency cycle -04: Triangular wave rising time coefficient Winding motor rotates Pendulum at uniform linear speed Reciprocating motor… -

Page 67

Operation, Display and Application Examples MD380 User Manual 4.8.9 Setting the Motor Rotating Direction After the AC drive restores the default settings, press to drive the motor to rotate. In this case, the rotating direction is regarded as the forward rotation. If the rotating direction is reverse to the direction required by the equipment, power off the AC drive and exchange any two of the output UVW cables (wait until the main capacitor of the AC drive is completely discharged). -

Page 68

MD380 User Manual Operation, Display and Application Example After the length is (Set length) reached, the DO becomes 1. 4-04 = 27 5-00 5-05 = 10 Length pulses ÷ (Number of (Length pulses (Length reached) pulses per input) (Actual length) meter) Clear to 0 Reset… -

Page 69

Operation, Display and Application Examples MD380 User Manual 4.8.11 Use of the Counting unction The count value needs to be collected by the DI terminal that is allocated with function 25. function 8 (Set count value reached) becomes ON. Then the counter stops counting. with function 9 (Designated count value reached) becomes ON. -

Page 70: Setting And Auto-Tuning Of Motor Parameters

MD380 User Manual Operation, Display and Application Example 4.9 Setting and Auto-tuning of Motor Parameters 4.9.1 Motor Parameters to e Set Motor parameters (motor 1 by default) that need to be set are listed in the following table. Table 4-2 Motor parameters to be set Parameter Description Remark…

-

Page 71

Operation, Display and Application Examples MD380 User Manual 4.9.2 Motor Auto-tuning To obtain the motor parameters, the AC drive can perform dynamic auto-tuning or static can input the motor parameters of the same model that was successfully auto-tuned before. Auto-tuning Application Result No-load dynamic… -

Page 72

MD380 User Manual Operation, Display and Application Example Then press on the operation panel. The AC drive will drive the motor to accelerate/ decelerate and run in the forward/reverse direction, and the RUN indicator is ON. The auto- tuning lasts approximately 2 minutes. When the preceding display information disappears and the operation panel returns to the normal parameter display status, it indicates that the auto-tuning is complete. -

Page 73: Use Of Di Terminals

Operation, Display and Application Examples MD380 User Manual 0-01 = 2 0-01 = 0 or 1 0-01 = 0 or 1 0-24 0-24 0-24 0-24 Motor 1 Motor 2 Motor 3 Motor 4 In the V/ In the vector control mode , up to 4 motors In the vector control mode , multiple motors can be can be driven at different time .

-

Page 74: Use Of Do Terminals

MD380 User Manual Operation, Display and Application Example 4.11 Use of DO Terminals output, and can drive 250 VAC control circuit. Terminal Corresponding unction Code Output eature Description Transistor, able to output high-speed pulses 10 Hz 5-06 when 5-00 = 0 to 100 kHz;…

-

Page 75: Use Of Ao Terminals

Operation, Display and Application Examples MD380 User Manual or feedback The user can preset up to 5 curves. Different AIs can use one curve. Curve 1: 4-13 to Curve 2: 4-18 to Curve 5: A6-08 to 4-17 4-22 A6-15 Unit’s digit: AI1 AI1 internal U0-09 Curve selection: 1 5…

-

Page 76: Use Of The

MD380 User Manual Operation, Display and Application Example 4.14 Use of the PG Terminal accuracy of the AC drive. In this case, it is necessary to install an encoder for the motor. Signals from the encoder are fed back to the AC drive through the PG card. The MD380 provides PG cards of four different types of signal features.

-

Page 77: Use Of Multifunctional Extension Interfaces

3.7 kW and above. card User User programmable extension card, Applied to the models programmable MD38PC1 completely compatible with Inovance’s of 3.7 kW and above. card H1U series PLC Differential Differential encoder interface card, encoder MD38PG1 Applied to all models.

-

Page 78: Password Setting

MD380 User Manual Operation, Display and Application Example 4.17 Password Setting zero value, the value is the user password. The password takes effect after you after exit the function code editing state. When you press again, «——» will be displayed, and you must enter the correct user password to enter the menu.

-

Page 79

Operation, Display and Application Examples MD380 User Manual efesotomasyon.com — 78 -… -

Page 80

Function Code Table efesotomasyon.com… -

Page 81: Chapter 5 Unction Code Table

Function Code Table MD380 User Manual Chapter 5 unction Code Table correct user password to enter the menu. function parameters. The symbols in the function code table are described as follows: » «: The parameter can be modi ed when the AC drive is in either stop or running state. «…

-

Page 82

MD380 User Manual Function Code Table unction Parameter Name Setting Range Default Property Code 5: Pulse setting (DI5) 6: Multi-reference Main frequency source X 0-03 7: Simple PLC selection 8: PID 9: Communication setting Auxiliary frequency source Y 0-04 selection frequency source X selection) 0: Relative to maximum frequency Range of auxiliary frequency… -

Page 83

Function Code Table MD380 User Manual unction Parameter Name Setting Range Default Property Code 0-12 requency upper limit 50.00 Hz 0.00 Hz to maximum frequency 0-13 requency upper limit offset 0.00 Hz 0.00 Hz to frequency upper limit 0-14 requency lower limit 0.00 Hz Model 0-15… -

Page 84

MD380 User Manual Function Code Table unction Parameter Name Setting Range Default Property Code panel command to frequency source) 0: No binding setting 2: AI1 3: AI2 4: AI3 5: Pulse setting (DI5) inding command source to 6: Multi-reference 0-27 frequency source 7: Simple PLC 8: PID… -

Page 85

Function Code Table MD380 User Manual unction Parameter Name Setting Range Default Property Code Stator resistance Model 1-06 (asynchronous motor) dependent Rotor resistance Model 1-07 (asynchronous motor) dependent 0.01–655.35 mH (AC drive power Leakage inductive reactance Model 1-08 (asynchronous motor) dependent 0.001–65.535 mH (AC drive 0.1–6553.5 mH (AC drive power… -

Page 86

MD380 User Manual Function Code Table unction Parameter Name Setting Range Default Property Code 1-31 Encoder installation angle 0.0°–359.9° 0.0° U, V, W phase sequence of 1-32 UVW encoder 1: Reverse 1-33 UVW encoder angle offset 0.0°–359.9° 0.0° Number of pole pairs of 1-34 1–65535 resolver… -

Page 87

Function Code Table MD380 User Manual unction Parameter Name Setting Range Default Property Code Excitation adjustment 2-13 0–20000 2000 proportional gain Excitation adjustment 2-14 0–20000 1300 integral gain Torque adjustment 0–20000 2-15 2000 proportional gain Torque adjustment integral 2-16 0–20000 1300 gain Unit’s digit: integral separation… -

Page 88

MD380 User Manual Function Code Table unction Parameter Name Setting Range Default Property Code Multi-point V/ frequency 2 3-05 0.00 Hz ( 2) Multi-point V/ voltage 2 3-06 0.0%–100.0% 0.0% (V2) Multi-point V/ frequency 3 Note: The rated frequencies 3-07 0.00 Hz ( 3) of motors 2, 3, and 4 are… -

Page 89

Function Code Table MD380 User Manual unction Parameter Name Setting Range Default Property Code Group 4: Input Terminals 0: No function 2: Reverse RUN (REV) 4-00 DI1 function selection 3: Three-line control 5: Reverse JOG (RJOG) 6: Terminal UP 7: Terminal DOWN 8: Coast to stop 10: RUN pause 4-01… -

Page 90

MD380 User Manual Function Code Table unction Parameter Name Setting Range Default Property Code 30: Pulse input (enabled only for DI5) 31:Reserved 32: Immediate DC braking 4-05 DI6 function selection 33: Normally closed (NC) input of external fault forbidden 35: Reverse PID action direction 36: External STOP terminal 1 37: Command source switchover terminal 2… -

Page 91

Function Code Table MD380 User Manual unction Parameter Name Setting Range Default Property Code Corresponding setting of AI 4-14 -100.00%–100.0% 0.0% curve 1 minimum input 4-15 AI curve 1 maximum input 10.00 V Corresponding setting of AI 4-16 -100.00%–100.0% 100.0% curve 1 maximum input 4-17 AI1 lter time… -

Page 92

MD380 User Manual Function Code Table unction Parameter Name Setting Range Default Property Code Unit’s digit (AI1 curve selection) Curve 4 (4 points, see A6-00 to 4-33 AI curve selection A6-07) Curve 5 (4 points, see A6-08 to A6-15) Ten’s digit (AI2 curve selection) Curve 1 to curve 5 (same as AI1) Hundred’s digit (AI3 curve selection) -

Page 93

Function Code Table MD380 User Manual unction Parameter Name Setting Range Default Property Code Thousand’s digit (DI4 valid mode) 0, 1 (same as DI1) 4-38 DI valid mode selection 1 00000 Ten thousand’s digit (DI5 valid mode) 0, 1 (same as DI1) Unit’s digit (DI6 valid mode) 0, 1 (same as DI1) Ten’s digit (DI7 valid mode) -

Page 94

MD380 User Manual Function Code Table unction Parameter Name Setting Range Default Property Code Extension card relay function 14: Torque limited 5-03 (P/A-P/ -P/C) 15: Ready for RUN O1 function selection (open- 16: AI1 larger than AI2 5-04 collector output terminal) (no output at stop) DO1 function selection 19: Undervoltage state output… -

Page 95

Function Code Table MD380 User Manual unction Parameter Name Setting Range Default Property Code 5-06 MP function selection 0: Running frequency 1: Set frequency 5-07 AO1 function selection 2: Output current 3: Output torque (absolute value) 4: Output power 5: Output voltage 6: Pulse input 7: AI1 8: AI2… -

Page 96

MD380 User Manual Function Code Table unction Parameter Name Setting Range Default Property Code 0: Positive logic 1: Negative logic Ten’s digit (Relay 1 valid mode) Hundred’s digit (Relay 2 valid mode) 5-22 DO valid mode selection 00000 Thousand’s digit (DO1 valid mode) Ten thousand’s digit (DO2 valid mode) -

Page 97

Function Code Table MD380 User Manual unction Parameter Name Setting Range Default Property Code Time proportion of S-curve 6-08 30.0% start segment Time proportion of S-curve 6-09 30.0% end segment 0: Decelerate to stop 6-10 Stop mode 1: Coast to stop Initial frequency of stop DC 6-11 0.00 Hz to maximum frequency… -

Page 98

MD380 User Manual Function Code Table unction Parameter Name Setting Range Default Property Code LED display running 7-03 parameters 1 it02: Pulse setting frequency (kHz) correction (V) correction (V) 3 voltage before correction (V) LED display running 7-04 it08: Linear speed parameters 2 it09: Current power-on time (Hour) -

Page 99

Function Code Table MD380 User Manual unction Parameter Name Setting Range Default Property Code 7-05 LED display stop parameters (kHz) Load speed display 7-06 0.0001–6.5000 1.0000 coef cient Heatsink temperature of 7-07 0.0–100.0°C inverter module 7-08 Temporary software version — 7-09 Accumulative running time 0–65535 h… -

Page 100

MD380 User Manual Function Code Table unction Parameter Name Setting Range Default Property Code Model 8-05 Acceleration time 3 0.0–6500.0s dependent Model 8-06 Deceleration time 3 0.0–6500.0s dependent Model 0.0–500.0s 8-07 Acceleration time 4 dependent Model 8-08 Deceleration time 4 0.0–6500.0s dependent 8-09… -

Page 101

Function Code Table MD380 User Manual unction Parameter Name Setting Range Default Property Code requency detection value 8-28 0.00 to maximum frequency 50.00 Hz ( DT2) requency detection 8-29 5.0% hysteresis ( DT hysteresis 2) Any frequency reaching 8-30 0.00 Hz to maximum frequency 50.00 Hz detection value 1 Any frequency reaching… -

Page 102

MD380 User Manual Function Code Table unction Parameter Name Setting Range Default Property Code Module temperature 8-47 0–100°C 75°C threshold 8-48 Cooling fan control 8-49 Wakeup frequency 0.00 Hz 8-50 Wakeup delay time 0.0–6500.0s 0.0s 8-51 Dormant frequency 0.00 Hz 8-52 Dormant delay time 0.0–6500.0s… -

Page 103

Function Code Table MD380 User Manual unction Parameter Name Setting Range Default Property Code 0: Disabled Output phase loss protection 9-13 selection 1: Enabled 9-14 1st fault type 0: No fault 1: Reserved 2: Overcurrent during acceleration 3: Overcurrent during deceleration 4: Overcurrent at constant speed 5: Overvoltage during acceleration… -

Page 104

MD380 User Manual Function Code Table unction Parameter Name Setting Range Default Property Code 40: With-wave current limit fault 41: Motor switchover fault during running 42: Too large speed deviation 9-16 3rd (latest) fault type 43: Motor over-speed 45: Motor overheat 51: Initial position fault 9-17 requency upon 3rd fault… -

Page 105

Function Code Table MD380 User Manual unction Parameter Name Setting Range Default Property Code Unit’s digit (Motor overload, Err11) 0: Coast to stop 1: Stop according to the stop mode 2: Continue to run Ten’s digit (Power input phase loss, Err12) Same as unit’s digit ault protection Hundred’s digit (Power output… -

Page 106

MD380 User Manual Function Code Table unction Parameter Name Setting Range Default Property Code Err27) Err28) Hundred’s digit (Accumulative power-on time reached, Err29) Thousand’s digit (Load becoming ault protection action 0, Err30) 9-49 00000 selection 3 0: Coast to stop 1: Stop according to the stop mode 2: Continue to run at 7% of rated… -

Page 107

Function Code Table MD380 User Manual unction Parameter Name Setting Range Default Property Code ackup frequency upon 0.0%–100.0% (maximum 9-55 100.0% abnormality frequency) 0: No temperature sensor Type of motor temperature 9-56 1: PT100 sensor 2: PT1000 Motor overheat protection 9-57 0–200°C 110°C… -

Page 108

MD380 User Manual Function Code Table unction Parameter Name Setting Range Default Property Code 0: AI1 1: AI2 2: AI3 3: AI1 – AI2 A-02 PID feedback source 4: Pulse setting (DI5) 5: Communication setting 6: AI1 + AI2 7: MAX (|AI1|, |AI2|) 8: MIN (|AI1|, |AI2|) A-03 PID action direction… -

Page 109

Function Code Table MD380 User Manual unction Parameter Name Setting Range Default Property Code Maximum deviation between A-24 two PID outputs in reverse 0.00%–100.00% 1.00% direction Unit’s digit (Integral separated) 0: Invalid 1: Valid Ten’s digit (Whether to stop A-25 PID integral property integral operation when the output reaches the limit) -

Page 110

MD380 User Manual Function Code Table unction Parameter Name Setting Range Default Property Code C-05 Reference 5 -100.0%–100.0% 0.0% C-06 Reference 6 -100.0%–100.0% 0.0% C-07 Reference 7 -100.0%–100.0% 0.0% C-08 Reference 8 -100.0%–100.0% 0.0% C-09 Reference 9 -100.0%–100.0% 0.0% C-10 Reference 10 -100.0%–100.0% 0.0%… -

Page 111

Function Code Table MD380 User Manual unction Parameter Name Setting Range Default Property Code Running time of simple PLC C-26 0.0–6553.5s (h) 0.0s (h) reference 4 Acceleration/deceleration time C-27 0–3 of simple PLC reference 4 Running time of simple PLC C-28 0.0–6553.5s (h) 0.0s (h) -

Page 112

MD380 User Manual Function Code Table unction Parameter Name Setting Range Default Property Code Acceleration/deceleration time C-47 0–3 of simple PLC reference 14 Running time of simple PLC C-48 0.0–6553.5s (h) 0.0s (h) reference 15 Acceleration/deceleration time C-49 0–3 of simple PLC reference 15 Time unit of simple C-50 0: s (second)1:h (hour) -

Page 113

Function Code Table MD380 User Manual unction Parameter Name Setting Range Default Property Code Group D: Communication Parameters Unit’s digit (Modbus baud rate) rate) D-00 aud rate 6005 Hundred’s digit (reserved) Thousand’s digit (CANlink baud rate) 0: 20 1: 50 2: 100 3: 125 4: 250… -

Page 114

MD380 User Manual Function Code Table unction Parameter Name Setting Range Default Property Code 0–20 ms D-03 Response delay 2 ms Valid for Modbus 0.0s (invalid) 0.1–60.0s D-04 Communication timeout 0.0s and CANopen Unit’s digit: Modbus protocol 0: Non-standard Modbus protocol 1: Standard Modbus protocol Modbus protocol selection format… -

Page 115

Function Code Table MD380 User Manual unction Parameter Name Setting Range Default Property Code E-15 User-de ned function code 15 6-10 E-16 User-de ned function code 16 0-00 E-17 User-de ned function code 17 0-00 E-18 User-de ned function code 18 0-00 E-19 User-de ned function code 19… -

Page 116

MD380 User Manual Function Code Table unction Parameter Name Setting Range Default Property Code parameter display selection) 0: Not display 1: Display Individualized P-03 parameter display property parameter display selection) 0: Not display 1: Display Parameter P-04 modi cation property Group A0: Torque Control and Restricting Parameters 0: Speed control Speed/Torque… -

Page 117

Function Code Table MD380 User Manual unction Parameter Name Setting Range Default Property Code A1-04 VDI5 function selection 0–59 Unit’s digit (VDI1) 0: Decided by state of VDOx 1: Decided by A1-06 Ten’s digit (VDI2) 0, 1 (same as VDI1) Hundred’s digit (VDI3) A1-05 VDI state setting mode… -

Page 118

MD380 User Manual Function Code Table unction Parameter Name Setting Range Default Property Code 0: Short with physical DIx internally A1-11 VDO1 function selection 1–40: Refer to function selection 0: Short with physical DIx internally A1-12 VDO2 function selection 1–40: Refer to function selection 0: Short with physical Dix internally A1-13… -

Page 119

Function Code Table MD380 User Manual unction Parameter Name Setting Range Default Property Code Group A2: Motor 2 Parameters 0: Common asynchronous motor 1: Variable frequency A2-00 Motor type selection asynchronous motor 2: Permanent magnetic synchronous motor Model A2-01 Rated motor power 0.1–1000.0 kW dependent Model… -

Page 120

MD380 User Manual Function Code Table unction Parameter Name Setting Range Default Property Code 0.01–655.35 mH (AC drive power Shaft D inductance Model A2-17 (synchronous motor) dependent 0.001–65.535 mH (AC drive 0.01–655.35 mH (AC drive power Shaft Q inductance Model A2-18 (synchronous motor) dependent… -

Page 121

Function Code Table MD380 User Manual unction Parameter Name Setting Range Default Property Code A2-42 Speed loop integral time 2 0.01–10.00s 1.00s A2-40 to maximum output A2-43 Switchover frequency 2 10.00 Hz frequency A2-44 Vector control slip gain 50%–200% 100% Time constant of speed loop A2-45 0.000–0.100s… -

Page 122

MD380 User Manual Function Code Table unction Setting Range Parameter Name Default Property Code 1: Closed-loop vector control A2-61 Motor 2 control mode (CLVC) control 0: Same as motor 1 1: Acceleration/Deceleration time 1 Motor 2 acceleration/ A2-62 2: Acceleration/Deceleration time 2 deceleration time 3: Acceleration/Deceleration time 3 4: Acceleration/Deceleration time 4… -

Page 123

Function Code Table MD380 User Manual unction Parameter Name Setting Range Default Property Code 0.01–655.35 mH (AC drive power Leakage inductive reactance Model A3-08 (asynchronous motor) dependent 0.001–65.535 mH (AC drive 0.1–6553.5 mH (AC drive power Mutual inductive reactance Model A3-09 (asynchronous motor) dependent… -

Page 124

MD380 User Manual Function Code Table unction Parameter Name Setting Range Default Property Code Number of pole pairs of A3-34 1–65535 resolver 0.0s: No action Encoder wire-break fault A3-36 0.0s detection time 0.1–10.0s 0: No auto-tuning 1: Asynchronous motor static auto-tuning 2: Asynchronous motor complete A3-37… -

Page 125

Function Code Table MD380 User Manual unction Parameter Name Setting Range Default Property Code Torque adjustment A3-53 0–20000 2000 proportional gain Torque adjustment integral A3-54 0–20000 1300 gain Unit’s digit: Integral separated A3-55 Speed loop integral property 0: Disabled 1: Enabled ield weakening mode of A3-56 1: Direct calculation… -

Page 126

MD380 User Manual Function Code Table unction Parameter Name Setting Range Default Property Code Model A4-02 Rated motor voltage 1–2000 V dependent 55 kW) Model A4-03 Rated motor current dependent 55 kW) Model A4-04 Rated motor frequency 0.01 Hz to maximum frequency dependent Rated motor rotational Model… -

Page 127

Function Code Table MD380 User Manual unction Parameter Name Setting Range Default Property Code ack EM (synchronous Model A4-20 0.1–6553.5 V motor) dependent Encoder pulses per A4-27 1–65535 1024 revolution 1: UVW incremental encoder A4-28 Encoder type 2: Resolver 3: SIN/COS encoder 4: Wire-saving UVW encoder phase sequence of A A4-30… -

Page 128

MD380 User Manual Function Code Table unction Parameter Name Setting Range Default Property Code Vector control over- A4-46 0–200 excitation gain 0: A2-48 1: AI1 2: AI2 3: AI3 Torque upper limit source in A4-47 speed control mode 4: Pulse setting (DI5) 5: Via communication 6: MIN(AI1,AI2) 7: MIN(AI1,AI2) -

Page 129

Function Code Table MD380 User Manual unction Parameter Name Setting Range Default Property Code 0: Same as motor 1 1: Acceleration/Deceleration time 1 Motor 2 acceleration/ A4-62 2: Acceleration/Deceleration time 2 deceleration time 3: Acceleration/Deceleration time 3 4: Acceleration/Deceleration time 4 0.0%: Automatic torque boost Model A4-63… -

Page 130

MD380 User Manual Function Code Table unction Parameter Name Setting Range Default Property Code Corresponding setting of AI A6-07 -100.0%–100.0% 100.0% curve 4 maximum input A6-08 AI curve 5 minimum input -10.00 V to A6-10 0.00 V Corresponding setting of AI A6-09 -100.0%–100.0% 0.0%… -

Page 131

Function Code Table MD380 User Manual unction Parameter Name Setting Range Default Property Code digital output) 0: Controlled by the AC drive 1: Controlled by the user programmable card Same as unit’s digit Selection of control mode of A7-01 the output terminals on the Hundred’s digit: DO1 control board Same as unit’s digit… -

Page 132

MD380 User Manual Function Code Table unction Parameter Name Setting Range Default Property Code 2: Reverse RUN Command given by the user A7-08 4: Reverse JOG programmable card 5: Coast to stop 6: Decelerate to stop 0: No fault aults given by the user A7-09 programmable card Group A8: Point-point Communication… -

Page 133

Function Code Table MD380 User Manual unction Parameter Name Setting Range Default Property Code actory AC-03 AI1 displayed voltage 2 6.000–9.999 V corrected actory AC-04 AI2 measured voltage 1 0.500–4.000 V corrected actory 0.500–4.000 V AC-05 AI2 displayed voltage 1 corrected actory AC-06… -

Page 134: Monitoring Parameters

MD380 User Manual Function Code Table unction Parameter Name Setting Range Default Property Code actory AC-24 AO1 ideal current 1 0.000–20.000 mA corrected actory AC-25 AO1 sampling current 1 0.000–20.000 mA corrected actory AC-26 AO1 ideal current 2 0.000–20.000 mA corrected actory AC-27…

-

Page 135

Function Code Table MD380 User Manual Communication unction Code Parameter Name Min. Unit Address Group U0: Standard Monitoring Parameters U0-23 AI3 voltage before correction 0.001 V 7017H U0-24 Linear speed 1 m/Min 7018H U0-25 Accumulative power-on time 1 Min 7019 U0-26 Accumulative running time 0.1 Min… -

Page 136

Description of Function Codes efesotomasyon.com… -

Page 137: Chapter 6 Description Of Unction Codes

Description of Function Codes MD380 User Manual Chapter 6 Description of unction Codes Group 0: asic Parameters unction Code Parameter Name Setting Range Default 1: G type (constant torque load) Model 0-00 G/P type display 2: P type (variable torque load e.g. fan dependent and pump) unction Code…

-

Page 138

ription of Function Codes MD380 User Manual Desc unction Code Parameter Name Setting Range Default 0: Operation panel control (LED off) Command 0-02 1: Terminal control (LED on) source selection 2: Communication control (LED blinking) It is used to determine the input channel of the AC drive control commands, such as run, stop, forward rotation, reverse rotation and jog operation. -

Page 139

Description of Function Codes MD380 User Manual It is used to select the setting channel of the main frequency. You can set the main frequency in the following 10 channels: 0: Digital setting (non-retentive at power failure) change the set frequency by pressing on the operation panel (or using the UP/DOWN function of input terminals). -

Page 140

ription of Function Codes MD380 User Manual Desc If a DI terminal is used for the multi-reference function, you need to perform related 7: Simple PLC When the simple programmable logic controller (PLC) mode is used as the frequency source, the running frequency of the AC drive can be switched over among the 16 frequency references. -

Page 141

Description of Function Codes MD380 User Manual unction Code Parameter Name Setting Range Default 0: Digital setting (non-retentive at power failure) 1: Digital setting (retentive at power failure) 2: AI1 3: AI2 Auxiliary 4: AI3 0-04 frequency source Y selection 5: Pulse setting (DI5) 6: Multi-reference 7: Simple PLC… -

Page 142

ription of Function Codes MD380 User Manual Desc unction Code Parameter Name Setting Range Default Unit’s digit ( requency source selection) 0: Main frequency source X 1: X and Y operation (operation relationship determined by ten’s digit) 2: Switchover between X and Y 3: Switchover between X and «X and Y requency source operation»… -

Page 143

Description of Function Codes MD380 User Manual unction Code Parameter Name Setting Range Default 0.00 to maximum frequency (valid when 0-08 Preset frequency 50 Hz frequency source is digital setting) If the frequency source is digital setting or terminal UP/DOWN, the value of this parameter is the initial frequency of the AC drive (digital setting). -

Page 144

ription of Function Codes MD380 User Manual Desc unction Code Parameter Name Setting Range Default 0: Set by 0-12 1: AI1 2: AI2 0-11 Source of frequency upper limit 3: AI3 4: Pulse setting (DI5) 5: Communication setting pulse setting or communication setting. If the frequency upper limit is set by means of AI1, AI2, AI3, DI5 or communication, the setting is similar to that of the main frequency source X. -

Page 145

Description of Function Codes MD380 User Manual table. Carrier frequency High Motor noise Large Small Output current waveform Good Motor temperature rise High AC drive temperature rise High Leakage current Small Large External radiation Small Large interference The factory setting of carrier frequency varies with the AC drive power. If you need to modify the carrier frequency, note that if the set carrier frequency is higher than factory setting, it will lead to an increase in temperature rise of the AC drive’s heatsink. -

Page 146

ription of Function Codes MD380 User Manual Desc Output frequency (Hz) Acceleration/Deceleration base frequency Set frequency Time (t) Actual deceleration time Actual acceleration time Set acceleration time Set deceleration time The MD380 provides totally four groups of acceleration/deceleration time for selection. You can perform switchover by using a DI terminal. -

Page 147

Description of Function Codes MD380 User Manual unction Code Parameter Name Setting Range Default 1: 0.1 Hz 0-22 requency reference resolution 2: 0.01 Hz It is used to set the resolution of all frequency-related parameters. If the resolution is 0.1 Hz, the MD380 can output up to 3200 Hz. If the resolution is 0.01 Hz, the MD380 can output up to 600.00 Hz. -

Page 148

ription of Function Codes MD380 User Manual Desc unction Code Parameter Name Setting Range Default 0: Maximum frequency ( 0-10) Acceleration/Deceleration 0-25 1: Set frequency time base frequency 2: 100 Hz The acceleration/deceleration time indicates the time for the AC drive to increase from 0 time is related to the set frequency. -

Page 149: Group 1: Motor 1 Parameters

Description of Function Codes MD380 User Manual unction Code Parameter Name Setting Range Default 0: Modbus protocol 0-28 Serial communication protocol 1: PRO I US-DP bridge 2: CANopen bridge protocol based on the actual requirements. Group 1: Motor 1 Parameters unction Code Parameter Name Setting Range…

-

Page 150

ription of Function Codes MD380 User Manual Desc unction Code Parameter Name Setting Range Default Mutual inductive 0.1–6553.5 mH (AC drive power 55 kW) Model reactance 1-09 dependent 0.01–-655.35 mH (AC drive power 55 kW) (asynchronous motor) No-load current 0.01 to 1-03 (AC drive power 55 kW) Model 1-10… -

Page 151

Description of Function Codes MD380 User Manual unction Code Parameter Name Setting Range Default 0: A incremental encoder 1: UVW incremental encoder 1-28 Encoder type 2: Resolver 3: SIN/COS encoder 4: Wire-saving UVW encoder The MD380 supports multiple types of encoder. Different PG cards are required for different types of encoder. -

Page 152

ription of Function Codes MD380 User Manual Desc unction Code Parameter Name Setting Range Default 1-34 Number of pole pairs of resolver 1–65535 If a resolver is applied, set the number of pole pairs properly. unction Code Parameter Name Setting Range Default 0.0s: No action Encoder wire-break fault detection… -

Page 153: Group 2: Vector Control Parameters

Description of Function Codes MD380 User Manual Set this parameter to 2, and press . Then, the AC drive starts complete auto- tuning. 11: Synchronous motor with-load auto-tuning It is applicable to scenarios where the synchronous motor cannot be disconnected from the load.

-

Page 154

ription of Function Codes MD380 User Manual Desc unction Code Parameter Name Setting Range Default 2-04 Speed loop integral time 2 0.01–10.00s 1.00s 2-02 to maximum 2-05 Switchover frequency 2 10.00 Hz output frequency Speed loop PI parameters vary with running frequencies of the AC drive. are obtained from the linear switchover between the two groups of PI parameters, as parameters 2-00… -

Page 155

Description of Function Codes MD380 User Manual unction Code Parameter Name Setting Range Default 2-07 Time constant of speed loop lter 0.000–0.100s 0.000s In the vector control mode, the output of the speed loop regulator is torque current oscillation, decrease the value of this parameter properly. If the value of this parameter is small, the output torque of the AC drive may fluctuate greatly, but the response is quick. -

Page 156

ription of Function Codes MD380 User Manual Desc unction Code Parameter Name Setting Range Default 2-13 Excitation adjustment proportional gain 0–20000 2000 2-14 Excitation adjustment integral gain 0–20000 1300 2-15 Torque adjustment proportional gain 0–20000 2000 2-16 Torque adjustment integral gain 0–20000 1300 These are current loop PI parameters for vector control. -

Page 157: Group 3: V/ Control Parameters

Description of Function Codes MD380 User Manual Group 3: V/ Control Parameters where one AC drive operates multiple motors or there is a large difference between the AC drive power and the motor power. unction Code Parameter Name Setting Range Default 0: Linear V/ 1: Multi-point V/…

-

Page 158

ription of Function Codes MD380 User Manual Desc unction Code Parameter Name Setting Range Default Model 3-01 Torque boost 0.0%–30% dependent Cut-off frequency of 0.00 Hz to maximum output 3-02 50.00 Hz torque boost frequency If the torque boost is set to too large, the motor may overheat, and the AC drive may suffer overcurrent. -

Page 159

Description of Function Codes MD380 User Manual between voltages and frequencies is: At low frequency, higher voltage may cause overheat or even burnt out of the motor and overcurrent stall or overcurrent protection of the AC drive. Voltage V1-V3: 1st, 2nd and 3rd voltage 1- 3: 1st, 2nd and 3rd frequency percentages of multi -point V / percentages of multi -point V /… -

Page 160

ription of Function Codes MD380 User Manual Desc Set the over-excitation gain to 0 in the applications where the inertia is small and the bus voltage will not rise during motor deceleration or where there is a braking resistor. unction Code Parameter Name Setting Range Default… -

Page 161

Description of Function Codes MD380 User Manual 5: Multi-reference determine the corresponding relationship between setting signal and setting voltage. voltage. 6: Simple PLC determine the setting output voltage. 7: PID 8: Communication setting The output voltage is set by the host computer by means of communication. voltage. -

Page 162: Group 4: Input Terminals

ription of Function Codes MD380 User Manual Desc Group 4: Input Terminals (DI6 to DI10) and an AI terminal (AI3). unction Code Parameter Name Default Remark 4-00 DI1 function selection 1: orward RUN ( WD) Standard 4-01 DI2 function selection 4: orward JOG ( JOG) Standard 4-02…

-

Page 163

Description of Function Codes MD380 User Manual Value unction Description The AC drive decelerates to stop, but the running parameters are all memorized, such as PLC, swing RUN pause frequency and PID parameters. After this function is disabled, the AC drive resumes its status before stop. If this terminal becomes ON, the AC drive reports Err15 Normally open (NO) input and performs the fault protection action. -

Page 164

ription of Function Codes MD380 User Manual Desc Value unction Description The AC drive is prohibited from torque control and Torque control prohibited enters the speed control mode. Pulse input (enabled only DI5 is used for pulse input. for DI5) Reserved Reserved. -

Page 165

Description of Function Codes MD380 User Manual Value unction Description When this terminal becomes ON, the AC drive stops within the shortest time. During the stop process, the Emergency stop current remains at the set current upper limit. This function is used to satisfy the requirement of stopping the AC drive in emergency state. -

Page 166

ription of Function Codes MD380 User Manual Desc different setting values. Two terminals for acceleration/deceleration time selection have four state combinations, as listed in the following table. Table 6-3 State combinations of two terminals for acceleration/deceleration time selection Acceleration/Deceleration Time Corresponding Terminal 2 Terminal 1… -

Page 167

Description of Function Codes MD380 User Manual 0: Two-line mode 1 It is the most commonly used two-line mode, in which the forward/reverse rotation of the motor is decided by DI1 and DI2. The parameters are set as below: unction Code Parameter Name Value unction Description… -

Page 168

ription of Function Codes MD380 User Manual Desc drive stops. 2: Three-line mode 1 In this mode, DI3 is RUN enabled terminal, and the direction is decided by DI1 and DI2. The parameters are set as below: unction Code Parameter Name Value unction Description 4-11… -

Page 169

Description of Function Codes MD380 User Manual MD380 button RUN command Running Stop direction button Stop running Running direction Reverse Digital common unction Code Parameter Name Setting Range Default 4-12 Terminal UP/DOWN rate 0.01–65.535 Hz/s 1.00 Hz/s It is used to adjust the rate of change of frequency when the frequency is adjusted by means of terminal UP/DOWN. -

Page 170

ription of Function Codes MD380 User Manual Desc details, refer to the description of different applications. Corresponding set value (frequency, torque) 100.0% 0 V (0 mA) 10 V (20 mA) Corresponding set value (frequency, torque) 100.0% 0 V (0 mA) 10 V (20 mA) -100.0% unction Code… -

Page 171

Description of Function Codes MD380 User Manual unction Code Parameter Name Setting Range Default 4-28 Pulse minimum input 0.00 kHz to 4-30 0.00 kHz Corresponding setting of 4-29 -100.00%–100.0% 0.0% pulse minimum input 4-30 Pulse maximum input 4-28 to 50.00 kHz 50.00 kHz Corresponding setting of 4-31… -

Page 172

ription of Function Codes MD380 User Manual Desc This parameter is used to determine the corresponding setting when the analog input voltage is less than the minimum value. The unit’s digit, ten’s digit and hundred’s digit of this parameter respectively correspond to the setting for AI2, AI2 and AI3. If the value of a certain digit is 0, when analog input voltage is less than the minimum input, If the value of a certain digit is 1, when analog input voltage is less than the minimum input, the corresponding value of this analog input is 0.0%. -

Page 173: Group 5: Output Terminals

Description of Function Codes MD380 User Manual These parameters are used to set the valid mode of DI terminals. 0: High level valid The DI terminal is valid when being connected with COM, and invalid when being disconnected from COM. 1: Low level valid The DI terminal is invalid when being connected with COM, and invalid when being disconnected from COM.

-

Page 174

ription of Function Codes MD380 User Manual Desc Value unction Description No output The terminal has no function. When the AC drive is running and has output frequency AC drive running (can be zero), the terminal becomes ON. When the AC drive stops due to a fault, the terminal ault output (stop) becomes ON. -

Page 175

Description of Function Codes MD380 User Manual Value unction Description Undervoltage state If the AC drive is in undervoltage state, the terminal output becomes ON. Communication Refer to the communication protocol. setting Reserved Reserved. Reserved Reserved. ero-speed running 2 If the output frequency of the AC drive is 0, the terminal (having output at stop) becomes ON. -

Page 176

ription of Function Codes MD380 User Manual Desc unction Code Parameter Name Default 5-06 MP function selection 5-07 AO1 function selection 5-08 AO2 function selection The output range of AO1 and AO2 is 0–10 V or 0–20 mA. The relationship between pulse and analog output ranges and corresponding functions is listed in the following table. -

Page 177

Description of Function Codes MD380 User Manual unction Code Parameter Name Setting Range Default 5-10 AO1 offset coef cient -100.0%–100.0% 0.0% 5-11 AO1 gain -10.00–10.00 1.00 5-12 AO2 offset coef cient -100.0%–100.0% 0.00% 5-13 AO2 gain -10.00–10.00 1.00 These parameters are used to correct the zero drift of analog output and the output If «b»… -

Page 178: Group 6: Start/Stop Control

ription of Function Codes MD380 User Manual Desc 0: Positive logic The output terminal is valid when being connected with COM, and invalid when being disconnected from COM. 1: Positive logic The output terminal is invalid when being connected with COM, and valid when being disconnected from COM.

-

Page 179

Description of Function Codes MD380 User Manual It is the commonly selected mode. It is applicable to restart after a long time of power failure. It is applicable to the power-generating load. unction Code Parameter Name Setting Range Default 6-02 Rotational speed tracking speed 1–100 In the rotational speed tracking restart mode, select the rotational speed tracking speed. -

Page 180

ription of Function Codes MD380 User Manual Desc unction Code Parameter Name Setting Range Default 6-05 Startup DC braking current/Pre-excited current 0%–100% 6-06 Startup DC braking time/Pre-excited time 0.0–100.0s 0.0s Startup DC braking is generally used during restart of the AC drive after the rotating motor motor before startup to improve the responsiveness. -

Page 181

Description of Function Codes MD380 User Manual When the set frequency is higher than the rated frequency, the acceleration/ deceleration time is: 4 ( ( ) In the formula, is the set frequency, is the rated motor frequency and is the acceleration time from 0 Hz to unction Code Parameter Name… -

Page 182

ription of Function Codes MD380 User Manual Desc unction Code Parameter Name Setting Range Default 0: Decelerate to stop 6-10 Stop mode 1: Coast to stop 0: Decelerate to stop After the stop command is enabled, the AC drive decreases the output frequency according to the deceleration time and stops when the frequency decreases to zero. -

Page 183

Description of Function Codes MD380 User Manual cancelled. Output frequency (Hz) Initial frequency of stop DC braking Time (t) Effective value of output voltage Waiting time of stop DC braking Stop DC braking Time t Stop DC braking time command unction Code Parameter Name Setting Range… -

Page 184: Group 7: Operation Panel And Display

ription of Function Codes MD380 User Manual Desc Group 7: Operation Panel and Display unction Code Parameter Name Setting Range Default 0: M .K key disabled 1: Switchover between operation panel control and remote command control (terminal or communication) M .K Key function 7-01 selection 2: Switchover between forward rotation…

-

Page 185

Description of Function Codes MD380 User Manual unction Parameter Setting Range Default Code Name 0000– 7 6 5 4 3 2 Running frequency 1 (Hz) Set frequency (Hz) Output voltage (V) Output current (A) Output power (kW) Output torque (%) DI input status (V) LED display 15 14… -

Page 186

ription of Function Codes MD380 User Manual Desc unction Parameter Setting Range Default Code Name 0000– 7 6 5 4 3 2 PID feedback PLC stage Pulse setting frequency (kHz) Running frequency 2 Remaining running time AI1 voltage before correction AI2 voltage before correction AI3 voltage before correction LED display… -

Page 187

Description of Function Codes MD380 User Manual unction Parameter Setting Range Default Code Name 0000– 7 6 5 4 3 2 Set frequency (Hz) DI input status DO output status AI1 voltage (V) AI2 voltage (V) AI3 voltage (V) Count value 7-05 display stop 15 14… -

Page 188: Group 8: Auxiliary Unctions

ription of Function Codes MD380 User Manual Desc unction Code Parameter Name Setting Range Default 7-09 Accumulative running time 0–65535 h It is used to display the accumulative running time of the AC drive. After the accumulative becomes ON. unction Code Parameter Name Setting Range Default…

-

Page 189

Description of Function Codes MD380 User Manual unction Code Parameter Name Setting Range Default 8-03 Acceleration time 2 0.0–6500.0s Model dependent 8-04 Deceleration time 2 0.0–6500.0s Model dependent 8-05 Acceleration time 3 0.0–6500.0s Model dependent 8-06 Deceleration time 3 0.0–6500.0s Model dependent 8-07 Acceleration time 4… -

Page 190

ription of Function Codes MD380 User Manual Desc unction Code Parameter Name Setting Range Default 8-12 orward/Reverse rotation dead-zone time 0.0–3000.0s 0.0s It is used to set the time when the output is 0 Hz at transition of the AC drive forward rotation Output frequency (Hz) -

Page 191

Description of Function Codes MD380 User Manual corresponding DO terminal becomes ON. reports an alarm when the actual accumulative power-on time reaches the threshold of 100 hours, perform the setting as follows: Set virtual DI1 to user-de ned fault 1: A1-00 = 44. Set that the valid state of virtual DI1 is from virtual DO1: A1-05 = 0000. -

Page 192

ription of Function Codes MD380 User Manual Desc These two parameters are respectively used to set the detection value of output frequency Output frequency (Hz) = 8-19 8-20 Time (t) detection signal (DO, relay) Time (t) unction Code Parameter Name Setting Range Default Detection range of frequency… -

Page 193

Description of Function Codes MD380 User Manual unction Code Parameter Name Setting Range Default 0: Disabled Jump frequency during 8-22 acceleration/deceleration 1: Enabled It is used to set whether the jump frequencies are valid during acceleration/deceleration. When the jump frequencies are valid during acceleration/deceleration, and the running frequency is within the frequency jump range, the actual running frequency will jump over the set frequency jump amplitude (rise directly from the lowest jump frequency to the highest valid during acceleration/deceleration. -

Page 194

ription of Function Codes MD380 User Manual Desc Output frequency (Hz) Set frequency 8-25 8-26 Time (t) Deceleration Acceleration time 2 time 2 Acceleration Deceleration time 1 time 1 time 1 is selected. time 2 is selected. unction Code Parameter Name Setting Range Default 0: Disabled… -

Page 195

Description of Function Codes MD380 User Manual unction Code Parameter Name Setting Range Default Any frequency reaching 0.0%–100.0% (maximum 8-33 0.0% detection amplitude 2 frequency) If the output frequency of the AC drive is within the positive and negative amplitudes of the any frequency reaching detection value, the corresponding DO becomes ON. -

Page 196

ription of Function Codes MD380 User Manual Desc unction Code Parameter Name Setting Range Default 0.0% (no detection) 8-36 Output overcurrent threshold 200.0% 0.1%–300.0% (rated motor current) Output overcurrent detection 8-37 0.00–600.00s 0.00s delay time If the output current of the AC drive is equal to or higher than the overcurrent threshold and the duration exceeds the detection delay time, the corresponding DO becomes ON. -

Page 197

Description of Function Codes MD380 User Manual Output current Any current reaching amplitude Any current reaching amplitude Any current reaching Any current reaching detection signal DO or relay unction Code Parameter Name Setting Range Default 0: Disabled 8-42 Timing function 1: Enabled 0: 8-44 1: AI1… -

Page 198

ription of Function Codes MD380 User Manual Desc unction Code Parameter Name Setting Range Default 0: an working during running 8-48 Cooling fan control 1: an working continuously It is used to set the working mode of the cooling fan. If this parameter is set to 0, the fan works when the AC drive is in running state. -

Page 199: Group 9: Ault And Protection

Description of Function Codes MD380 User Manual Group 9: ault and Protection Setting Range unction Code Parameter Name Default 0: Disabled 9-00 Motor overload protection selection 1: Enabled 0.20–10.00 9-01 Motor overload protection gain 1.00 The motor overload protective function is disabled. The motor is exposed to potential damage due to overheating.

-

Page 200

ription of Function Codes MD380 User Manual Desc result will be poor and an overvoltage fault may occur. If the overvoltage stall gain is set to 0, the overvoltage stall function is disabled. The overvoltage stall protective voltage setting 100% corresponds to the base values in the following table: Table 6-7 Overvoltage stall protective voltage setting 100% corresponds to base values Voltage Class… -

Page 201

Description of Function Codes MD380 User Manual Output current Overcurrent stall protective current Time (t) Output frequency (Hz) frequency Time (t) Acceleration Constant- Deceleration process speed process process unction Code Parameter Name Setting Range Default 0: Disabled Short-circuit to ground upon power- 9-07 1: Enabled It is used to determine whether to check the motor is short-circuited to ground at power-on… -

Page 202

ription of Function Codes MD380 User Manual Desc unction Code Parameter Name Setting Range Default Unit’s digit: Input phase loss protection Input phase loss Ten’s digit: Contactor energizing protection/contactor protection 9-12 energizing protection 0: Disabled selection 1: Enabled It is used to determine whether to perform input phase loss or contactor energizing protection. -

Page 203

Description of Function Codes MD380 User Manual unction Code Parameter Name Description It displays the status of all DI terminals when the latest fault occurs. The sequence is as follows: 9-20 DI status upon 3rd fault If a DI is ON, the setting is 1. If the DI is O the setting is 0. -

Page 204

ription of Function Codes MD380 User Manual Desc unction Code Parameter Name Setting Range Default Unit’s digit (Motor overload, Err11) 0: Coast to stop 1: Stop according to the stop mode 2: Continue to run Ten’s digit (Power input phase loss, Err12) Same as unit’s digit ault protection 9-47… -

Page 205

Description of Function Codes MD380 User Manual unction Code Parameter Name Setting Range Default Unit’s digit (User-de ned fault 1, Err27) Same as unit’s digit in 9-47 Ten’s digit (User-de ned fault 2, Err28) Same as unit’s digit in 9-47 Hundred’s digit (Accumulative power-on time reached, Err29) Same as unit’s digit in 9-47… -

Page 206

ription of Function Codes MD380 User Manual Desc If a fault occurs during the running of the AC drive and the handling of fault is set to «Continue unction Code Parameter Name Setting Range Default 0: No temperature sensor 9-56 Type of motor temperature sensor 1: PT100 2: PT1000… -

Page 207

Description of Function Codes MD380 User Manual Voltage rally judging time at instantaneous power failure 9-61 Action judging voltage at instantaneous power failure 9-62 Running frequency Action pause judging voltage at instantaneous 9-59 = 1: Decelerate power failure 9-60 Deceler Deceler Acceler -ation… -

Page 208: Group A: Process Control Pid Unction

ription of Function Codes MD380 User Manual Desc unction Code Parameter Name Setting Range Default Detection value of too large 0.0%–50.0% (maximum 9-69 20.0% speed deviation frequency) Detection time of too large speed 9-70 0.0–60.0s 5.0s deviation This function is valid only when the AC drive runs in the CLVC mode. If the AC drive detects the deviation between the actual motor rotational speed detected by protection action.

-

Page 209

Description of Function Codes MD380 User Manual unction Code Parameter Name Setting Range Default 0: AI1 1: AI2 2: AI3 3: AI1 – AI2 A-02 PID feedback source 4: Pulse setting (DI5) 5: Communication setting 6: AI1 + AI2 7: MAX (|AI1|, |AI2|) 8: MIN (|AI1|, |AI2|) This parameter is used to select the feedback signal channel of process PID. -

Page 210

ription of Function Codes MD380 User Manual Desc It decides the regulating intensity of the PID regulator. The higher the Kp1 is, the larger the regulating intensity is. The value 100.0 indicates when the deviation between PID feedback and PID setting is 100.0%, the adjustment amplitude of the PID regulator on the output frequency reference is the maximum frequency. -

Page 211

Description of Function Codes MD380 User Manual unction Code Parameter Name Setting Range Default A-12 PID feedback lter time 0.00–60.00s 0.00s A-13 PID output lter time 0.00–60.00s 0.00s slowing the response of the process closed-loop system. drive output frequency but slowing the response of the process closed-loop system. unction Code Parameter Name Setting Range… -

Page 212

ription of Function Codes MD380 User Manual Desc parameters Group 1 of PID parameters -05, -06, Group 2 of PID parameters -15, -16, PID deviation unction Code Parameter Name Setting Range Default A-21 PID initial value 0.0%–100.0% 0.0% A-22 PID initial value holding time 0.00–650.00s 0.00s When the AC drive starts up, the PID starts closed-loop algorithm only after the PID output… -

Page 213: Group : Swing Requency, Ixed Length And Count

Description of Function Codes MD380 User Manual unction Code Parameter Name Setting Range Default Unit’s digit (Integral separated) 0: Invalid 1: Valid A-25 PID integral property Ten’s digit (Whether to stop integral operation when the output reaches the limit) 0: Continue integral operation 1: Stop integral operation Integral separated If it is set to valid, , the PID integral operation stops when the DI allocated with function…

-

Page 214

ription of Function Codes MD380 User Manual Desc is 0 and the swing frequency does not take effect. Output Swing amplitude frequency (Hz) Aw = Swing frequency upper limit Swing frequency lower limit Textile kick frequency Time (t) Swing Accelerate by Decelerate by Triangular cycle… -

Page 215

Description of Function Codes MD380 User Manual unction Code Parameter Name Setting Range Default Swing frequency cycle 0.0–3000.0s 10.0s Triangular wave rising time coef cient 0.0%–100.0% 50.0% frequency cycle). unction Code Parameter Name Setting Range Default Set length 0–65535 m 1000 m Actual length 0–65535 m… -

Page 216: Group C: Multi-Reference And Simple Plc Unction

ription of Function Codes MD380 User Manual Desc U0-12: Count value Count pulses input 20 21 U0-12 = 0 Count pulses input -09 = 11 Designated count U0-12 = 11 value reached output -08 = 20 Set count value U0-12 = 20 reached output Group C: Multi-Reference and Simple PLC unction addition, the multi-reference is relative value.

-

Page 217

Description of Function Codes MD380 User Manual unction Code Parameter Name Setting Range Default 0: Stop after the AC drive runs one cycle Simple PLC 1: Keep nal values after the AC drive runs C-16 running mode one cycle 2: Repeat after the AC drive runs one cycle 0: Stop after the AC drive runs one cycle The AC drive stops after running one cycle, and will not start up until receiving another command. -

Page 218

ription of Function Codes MD380 User Manual Desc unction Code Parameter Name Setting Range Default Unit’s digit (Retentive upon power failure) 0: No Simple PLC 1: Yes C-17 retentive selection Ten’s digit (Retentive upon stop) 0: No 1: Yes PLC retentive upon power failure indicates that the AC drive memorizes the PLC running moment and running frequency before power failure and will continue to run from the memorized moment after it is powered on again. -

Page 219

Description of Function Codes MD380 User Manual unction Code Parameter Name Setting Range Default C-34 Running time of simple PLC reference 8 0.0–6553.5s (h) 0.0s (h) Acceleration/deceleration time of simple C-35 0–3 PLC reference 8 C-36 Running time of simple PLC reference 9 0.0–6553.5s (h) 0.0s (h) Acceleration/deceleration time of simple… -

Page 220: Group D: User-De Ned Parameters

ription of Function Codes MD380 User Manual Desc Group D: User-de ned Parameters Group E: User-De ned unction Codes unction Code Parameter Name Setting Range Default 0-00 to P-xx, A0-00 to 0-00 E-00 User-de ned function code 0 Ax-xx, U0-xx E-01 User-de ned function code 1 Same as E-00…

-

Page 221: Group P: User Password

Description of Function Codes MD380 User Manual Group P: User Password unction Code Parameter Name Setting Range Default P-00 User password 0–65535 If it is set to any non-zero number, the password protection function is enabled. After a password has been set and taken effect, you must enter the correct password in order to enter the menu.

-

Page 222

ription of Function Codes MD380 User Manual Desc unction Code Parameter Name Setting Range Default Unit’s digit (Group U display selection) 0: Not display AC drive 1: Display P-02 parameter display Ten’s digit (Group A display selection) property 0: Not display 1: Display Unit’s digit (User-de ned parameter display selection) -

Page 223: Group A0: Torque Control And Restricting Parameters

Description of Function Codes MD380 User Manual The MD380 provides display of two types of individualized parameters: user-defined parameters, convenient for commissioning. unction Code Name Setting Range Default 0: Modi able P-04 Parameter modi cation property 1: Not modi able Group A0: Torque Control and Restricting Parameters unction Code Parameter Name…

-

Page 224

ription of Function Codes MD380 User Manual Desc A0-01 is used to set the torque setting source. There are a total of eight torque setting sources. The torque setting is a relative value. 100.0% corresponds to the AC drive’s rated torque. The setting range is -200.0% to 200.0%, indicating the AC drive’s maximum torque is twice of the AC drive’s rated torque. -

Page 225: Group A1: Virtual Di (Vdi)/Virtual Do (Vdo)

Description of Function Codes MD380 User Manual If the communication mode is used, a communication card must be installed. The MD380 provides four optional communication cards and you can select one based or CANopen, the corresponding serial communication protocol needs to be selected The CANlink protocol is always valid.

-

Page 226

ription of Function Codes MD380 User Manual Desc unction Code Parameter Name Setting Range Default A1-03 VDI4 function selection 0–59 A1-04 VDI5 function selection 0–59 VDI1 to VDI5 have the same functions as DI terminals on the control board and can be used unction Code Parameter Name Setting Range… -

Page 227

Description of Function Codes MD380 User Manual When the AI1 input exceeds the limit, VDO1 becomes ON. At this moment, VDI1 Err27 and stops. Decided by A1-06 the function that the AC drive automatically enters the running state after power-on, perform the following setting: Allocate VDI1 with function 1 «… -

Page 228

ription of Function Codes MD380 User Manual Desc AI input voltage 7 VDC 3 VDC Time AI terminal state unction Code Parameter Name Setting Range Default 0: Short with physical DIx internally A1-11 VDO1 function selection 1–40: Refer to function selection of physical DO in group 5. -

Page 229: Group A2 To A4: Motor 2 To Motor 4 Parameters

Description of Function Codes MD380 User Manual unction Code Parameter Name Setting Range Default Unit’s digit (VDO1) 0: Positive logic 1: Reverse logic Ten’s digit (VDO2) 0, 1 (same as unit’s digit) A1-21 VDO state selection Hundred’s digit (VDO3) 00000 0, 1 (same as unit’s digit) Thousand’s digit (VDO4) 0, 1 (same as unit’s digit)

-

Page 230

ription of Function Codes MD380 User Manual Desc unction Code Parameter Name Setting Range Default Model A2-01 Rated motor power 0.1–1000.0 kW dependent Model A2-02 Rated motor voltage 1–2000 V dependent 0.01–655.35 A (AC drive power 55 kW) Model A2-03 Rated motor current dependent 0.1–6553.5 A (AC drive power… -

Page 231

Description of Function Codes MD380 User Manual unction Code Parameter Name Setting Range Default Encoder installation A2-31 0.0°–359.9° 0.0° angle U, V, W phase 0: orward A2-32 sequence of UVW 1: Reverse encoder UVW encoder angle 0.0°–359.9° 0.0° A2-33 offset Number of pole pairs A2-34 1–65535… -

Page 232

ription of Function Codes MD380 User Manual Desc unction Code Parameter Name Setting Range Default Digital setting of A2-48 torque upper limit in 0.0%–200.0% 150.0% speed control mode Excitation adjustment A2-51 2000 0–20000 proportional gain Excitation adjustment 1300 A2-52 0–20000 integral gain Torque adjustment A2-53… -

Page 233: Group A5: Control Optimization Parameters