-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

Liebert NXr

Liebert NX

30 to 200 kVA UPS cubicles

parallelable to 800kVA

Related Manuals for Emerson NXr

Summary of Contents for Emerson NXr

-

Page 1

Liebert NX Liebert NXr 30 to 200 kVA UPS cubicles parallelable to 800kVA… -

Page 2: User Manual

Revision date 2011 0401 (ENPAu 2011 1108) 31012244 Emerson Network Power provides customers with technical support. Users may contact the nearest Emerson local sales office or service center. Copyright © 2010 by Emerson Network Power Co., Ltd. All rights reserved. The contents in this document are subject to change without notice.

-

Page 3: Safety Precaution

Failure to observe this could result in personnel safety risk, equipment malfunction and invalidation of warranty. The NXr UPS is only used for commercial or industrial purpose and cannot be used as life support equipment. This is a C2 type UPS product. In a domestic environment, this product may cause radio frequency interference, in which case, the user may be required to take additional measures.

-

Page 4

Battery voltage higher than 400Vdc All the battery physical maintenance and servicing procedures need special tools or keys and should be carried out only by trained personnel. Take special care when working with the batteries associated with this UPS. When the batteries are connected together, the battery terminal voltage exceeds 400vdc and is potentially leathal. -

Page 6: Table Of Contents

Contents Chapter 1 Installation Of single UPS cubicle ……………………1 1.1 Brief Introduction …………………………1 1.2 Initial Check …………………………..1 1.3 Location Selection …………………………2 1.3.1 UPS Room …………………………2 1.3.2 External Battery Room……………………..2 1.3.3 Storage …………………………

-

Page 7

2.5 Battery Recycling …………………………20 2.6 Connection Of External Battery Circuit-Breaker (BCB ………………20 Chapter 3 Installation Of Multiple UPS cubicles …………………… 22 3.1 Overview …………………………..22 3.2 1 + N Parallel System ……………………….22 … -

Page 8

5.2.1 Start Screen ……………………….. 34 5.2.2 Primary Screen ……………………….34 5.2.3 Default Screen ……………………….35 5.3 Selecting Language ……………………….35 5.4 Changing The Current Date And Time …………………… 35 5.5 Control Password …………………………35 5.6 Detailed Description Of Menu Items …………………… -

Page 9

8.8 Efficiency, Heat Losses And Air Exchange ………………….54 Appendix 1 Option List …………………………55 Appendix 2 List Of Abbreviations ……………………….56 … -

Page 10: Chapter 1 Installation Of Single Ups Cubicle

Chapter 1 Installation Of UPS Module Chapter 1 Installation Of single UPS cubicle This chapter introduces the installation of Emerson NXr 30kVA ~ 200kVA UPS (hereinafter referred to as UPS) module, including the initial check, location selection, positioning, external protective device and cable connection.

-

Page 11: Location Selection

During storage, periodically charge the battery according to the battery manufacturer instructions. In the charge process, temporarily connect the UPS to the mains and activate the battery for the time required for recharging the battery. NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 12: Positioning

UPS base. If the UPS is mounted on raised floor, a suitable pedestal should be designed, which should be able to bear the UPS weight. When designing the pedestal, refer to the bottom view in Figure 1-1 and Figure 1-2. NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 13

Chapter 1 Installation Of UPS Module Front view Side view Anchor hole Top view Bottom view A amplified view ~ Figure 1-1 30kVA 160kVA UPS installation dimensions (unit: mm) NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual… -

Page 14: Cable Entry

External circuit breakers or other protective devices must be fitted at the input AC supply of the UPS. This section provides a general guide for qualified installation engineers. The installation engineers should have the knowledge of the local wiring regulations on the equipment to be installed. NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 15: Rectifier And Bypass Input

380V 400V 415V 380V 400V 415V Bolt Bolt Torque (N.m) (N.m) 150, 160 90 、 100 30-B Note: 1. Input mains current for common rectifier and bypass AC input. NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 16: Distance From Floor To Connection Point On The Equipment

Once the equipment has been finally positioned and secured, refer to Figure 1-3 to connect the power cables as described in the following procedures: NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 17

2. Open the UPS door and remove the protective cover at the lower part in the front to gain access to the power terminals, as shown in Figure 1-4 to Figure 1-6. NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual… -

Page 18

Chapter 1 Installation Of UPS Module Figure 1-4 30kVA (NXr 30K-B) UPS power terminals NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual… -

Page 19

2. Bypass input: bA, bB, bC, mN 3. UPS output: oA, oB, oC, oN 4. Battery input: + , — , N 5. Earth: PE Figure 1-6 200kVA UPS power terminals NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual… -

Page 20

(+) to (+) and (–) to (–), but disconnect one or more battery cell links in each tier. Do not reconnect these links and do not close the BCB before authorized by the commissioning engineer. 6. For frequency converter applications ensure the bypass links are removed. 7. Replace the protective cover. NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual… -

Page 21: Control Cables And Communication

+12V power J8.1 BAT_IN Internal battery temperature detection J8.2 +12V +12V power J8.3 BAT_OUT External battery temperature detection J8.4 Power ground Note*: Activating this feature turns off the battery charger NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 22: Battery Circuit-Breaker (Bcb) Port

IN_S J9.2 shorted to J9.4 when Internal maintenance switch is closed J9.3 EXT_OUT External output isolator (EOI) Aux Contact closed to J9.4 when EOI is closed. J9.4 Power ground NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 23: Backfeed Protection Output Dry Contact Port

Pins 1 and 2 of J10 are supplied factory-shorted. If the UPS EPO function is not used, pins 1 and 2 of J10 must remain shorted and pins 3 and 4 of J10 must remain open . NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 24: Relay And Network Interface Card Ports, Service Ports

For details, refer to the user manuals of the each specific network interface card. Service ports J2 and J3: Parallel connection ports — used for control of two or more NXr UPS cabinets operating in parallel. J4: Load Bus Synch (LBS) interface — used to synchronize the outputs of two NXr UPS systems operating in dual bus mode.

-

Page 25: Chapter 2 Battery

Batteries of different brand, model and age should nottbe used together. Except for the NXr 30K-B model that contains internal batteries, all UPS batteries are located external to the UPS cabinet and is normally housed in a battery cabinet or located on stands/racks.

-

Page 26: Safety

12) Before connecting or disconnecting the battery connection cables, please cut off the charging power. 13) Check if the battery has been unexpectedly earthed. If yes, remove the earth power. Contact with any part of the earthed battery may cause electric shock. NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 27: Battery Power Cable

8. Refer to Figure 2-1 and Figure 2-2 for the battery cable connection. 9. For NXr 30K-B UPS, it is required to install the factory supplied separators between the two rows of batteries on each layer of the battery compartment, as shown in Figure 2-2.

-

Page 28: Battery Maintenance

Figure 2-2 Internal battery cable connection (NXr 30K-B) 2.4 Battery Maintenance The battery supplied by Emerson complies with the safety requirements of IEC 62040-1:2008. For the battery maintenance and maintenance precautions, refer to the relevant manual provided by the battery manufacturer and observe applicable local regulation e.g.

-

Page 29: Battery Recycling

Emerson, please consult the local customer service center or sales office of Emerson. If the customer refuses to accept this special note or does not use the disused battery recycling system of Emerson. Emerson will not undertake any environment responsibility caused by the improper disposal of the disused battery products.

-

Page 30

Auxiliary Bypass module contactor BCB control board UHW241C2 X101 X102 X108 +12V +12V BAT -T BAT-T GND2 GND1 Figure 2-6 Connections between UPS, BCB and BCB control board (option) NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual… -

Page 31: Chapter 3 Installation Of Multiple Ups Cubicles

The basic installation steps of parallel system are the same as those of the single UPS cubicle. The following sections describe the differences between the parallel system installation and single UPS installation. NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

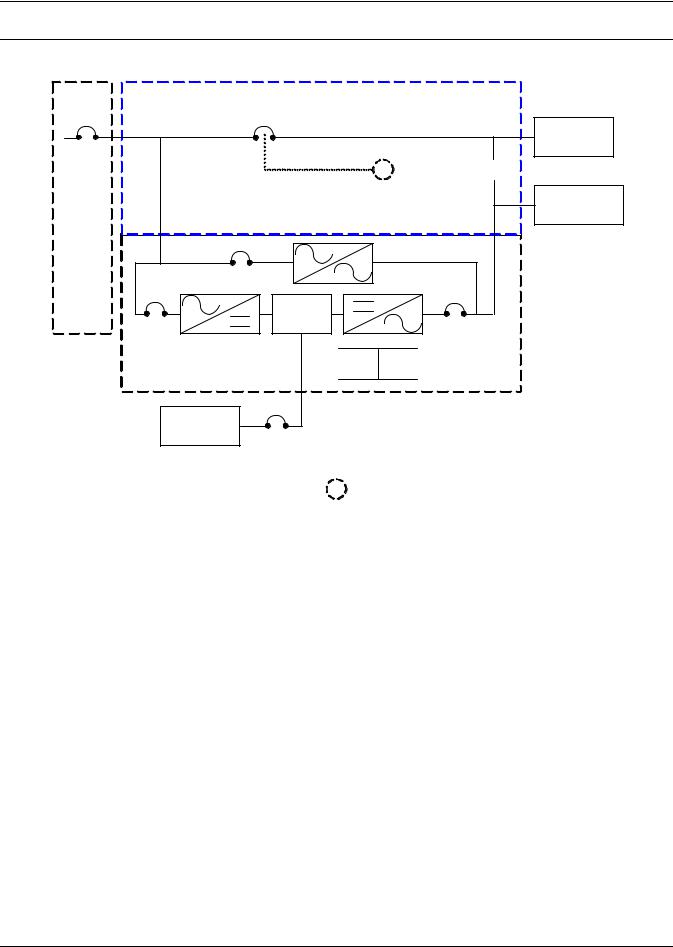

Page 32: Cabinet Installation

UPS output switches and maintenance bypass must be installed, as shown in Figure 3-2, to facilitate maintenance and system testing. Figure 3-2 Typical “1+N” system schematic diagram (with common input, separate battery and output/bypass distribution cabinet) NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 33: External Protective Device

. Note The length and specification of power cables including the bypass input cables and UPS output cables should be the same. This facilitates load sharing in bypass mode. NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 34: Auxiliary Control Wiring

Be sure to verify the reliable cable connection before starting up the system. UPS 1 UPS 3 UPS 4 UPS 2 Figure 3-5 Connection of parallel control cables of 1+N parallel system NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 35: Dual Bus System

3.3.4 Control Cable For NXr-to-NXr dual bus system, connect the optional LBS cables between the LBS ports (J4) of the two parallel systems, as shown in Figure 3-8. The LBS port (J4) is provided on the front panel of the bypass module, as shown in Figure 3-6.

-

Page 36

Chapter 3 Installation Of Parallel System UPS 1 UPS 2 UPS 3 UPS 4 Bypass module Bypass module Bypass module Bypass module LBS cable LBS cable Figure 3-8 Connection of typical dual bus system NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual… -

Page 37: Chapter 4 System Description

(no-break) load transfer between the inverter output and static bypass line. The synchronization between the inverter output and static bypass is achieved through the inverter control electronics, which make the NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 38: N Parallel System

The UPS is an on-line, double-conversion, reverse-transfer UPS that permits operation in these modes: Normal mode Battery mode (“stored energy mode”) Automatic restart mode Bypass mode Maintenance mode (manual bypass) Parallel redundancy mode NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 39: Normal Mode

The boost charge voltage can be set as required by the type of battery. For valve-regulated lead-acid (VRLA batteries, the maximum boost charge voltage should not exceed 2.4V/cell. 3. Float charge. NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 40: Advanced Function

The battery disconnect device alarm occurs when the battery disconnect device disconnects. The external battery connects to the UPS through the external BCB. The BCB is manually closed and tripped by the UPS control circuit. NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 41: Chapter 5 Operator Control And Display Panel

State Description Solid green Rectifier in normal operation Flashing green Mains input normal, but rectifier not operating Rectifier indicator Solid red Rectifier fault Rectifier not operating, mains input abnormal NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 42: Audible Alarm (Buzzer)

The operator control and display panel provides an LCD and five menu keys (F1 ~ F5). The menu keys are described in Table 5-5. Table 5-5 Menu key description Function 1 Escape HOME Left Right Enter Function 2 Down NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 43: Lcd Screen Type

The functions of the menu keys F1 ~ F5 for the current screen are shown by self-explanatory icons in the keypad window as appropriate. From any menu on the primary screen, pressing the F1 key returns to the Output menu。 NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 44: Default Screen

This password provides access to UPS and battery test functions. 5.6 Detailed Description Of Menu Items The description that follows refers to the LCD primary screen shown in Figure 5-3. NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 45

Displays the alarm history. For the list of the alarms that may be displayed on Records (alarm history) the LCD on the UPS operator control and display panel, refer to Table 5-9 Language (language option) Provides 12 optional LCD languages NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual… -

Page 46: Prompt Window

This prompt appears to require your confirmation. Cancelling the test will ends cancel the test and transfers the UPS to Normal mode System self test finished, everything is No action required NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 47: Alarm List

UPS. If the bypass voltage and frequency are abnormal, check the external bypass supply. 4. If the mains is likely to trigger this alarm frequently, the bypass limits can be changed to a wider NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 48

The neutral line of the AC input mains is not detected The battery ground fault option has detected a battery ground fault. Contact the local customer service Battery ground fault center of Emerson to inspect the battery installation NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual… -

Page 49

Rectifier software being updated Inv Flash Update Inverter software being updated Monitor Flash Update Monitoring software being updated Bypass Flash Update Bypass software being updated LBS abnormal LBS abnormal NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual… -

Page 50: Chapter 6 Operating Instructions

The UPS provides a maintenance switch only (silkscreen: MAINTAIN CB), as shown in Figure 6-1 to Figure 6-3. The user needs to provide the other switches. Maintenance switch Figure 6-1 Location of maintenance switch of 30kVA (NXr 30K-B) UPS NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 51: Ups Startup Procedures

Chapter 6 Operating Instructions Maintenance switch Figure 6-2 Location of maintenance switch of 30kVA (NXr 30K) ~ 160kVA UPS Maintenance switch Figure 6-3 Location of maintenance switch of 200kVA UPS 6.2 UPS Startup Procedures It is assumed that the installation is complete, the system has been commissioned by authorized personnel, and the external power isolators are closed.

-

Page 52: Procedures For Startup Into Normal Mode

At this point, the LCD starts up, and the battery indicator starts flashing in green color. After the rectifier has operated normally for 30s, the battery indicator stops flashing and becomes solid green. 电池启动按钮 Battery start button Figure 6-4 Location of battery start button Note NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 53: Procedures For Transfer Between Operation Modes

1. If you need to maintain a faulty module, wait for 10min to let the internal DC bus capacitor fully discharge before removing the faulty module for maintenance. 2. When the UPS in operating in maintenance mode, the neutral line is still energized. Therefore, only qualified personnel shall NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 54: Procedures For Completely Powering Down The Ups

4. Open the output switch of the UPS. 6.6 Isolation Procedures (Of One UPS In A Parallel System) Caution The following procedures will switch off all power to the load. NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 55: Insertion Procedures (Of One Ups In A Parallel System)

In the case of a mains failure, the UPS draws power from the battery system to supply the load until the batteries are depleted. When the UPS reaches its end of EOD threshold, it shut will down. The UPS will automatically restart and enable output power: NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 56: Ups Reset Procedures

UPS. 2. If you need to maintain a faulty module, wait for 10min to let the internal DC bus capacitor fully discharge before removing the faulty module for maintenance. NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 57: Chapter 7 Service

If the UPS has been transferred to bypass, press and hold the INVERTER ON button for two seconds to start up all power modules. 7.1.3 Service Procedures Of Bypass Module Provided that the UPS is in normal mode, and that the bypass is normal: NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 58: Replacement Procedures Of Air Filter

5. Tighten the fixing screws of the fixing bar on the other side. Fixing screw Fixing bar Fixing bar Air filter Figure 7-1 Replacing air filter of 30kVA ~ 160kVA UPS NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 59

Chapter 7 Service Fixing screw Fixing bar Fixing bar Air filter Figure 7-2 Replacing air filter of 200kVA UPS NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual… -

Page 60: Chapter 8 Product Specification

600 × 843 × 1400 600 × 843 × 1600 Weight (excluding battery) Color Charcoal Grey ZP7021 / RAL 7021 Protection degree, IEC(60529) IP20 (front door open or closed) NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 61: Electrical Characteristics (Input Rectifier)

2.4 (selectable from 2.30V/cell to 2.40V/cell) Constant current and constant voltage charge mode Programmable automatic trigger or inhibit of boost mode Battery 13.5 22.5 charging power and max charging 14.7 current (adjustable) NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 62: Electrical Characteristics (Inverter Output)

Current rating of neutral 1.7 × In cable Frequency 50/60 Synchronous transfer: ≤1 Transfer time (between Asynchronous transfer (default): 15 (50Hz), 13.3 (60Hz); or 40, 60, 80, 100 bypass and inverter) selectable NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 63

Heat losses & air exchange Normal mode No load Maximum forced air cooling (front L/sec intake, rear exhaust) Note: 400Vac input and output, battery fully charged, full-rated linear load NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual… -

Page 64: Option List

Applicable to 30kVA (NXr 30K) ~ 100kVA UPS Bypass load sharing inductor UF-NRBYPCK-160 02354042 Applicable to 120kVA ~ 160kVA UPS Bypass load sharing inductor UF-NRBYPCK-200 02354314 Applicable to 200kVA UPS NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

-

Page 65

MCCB Moulded-case circuit breaker Center tap Battery circuit breaker Load bus synchronizer Pulse width modulation Full digital control Static transfer switch VRLA Valve-regulated lead-acid liquid crystal display Electromagnetic compatibility NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual…

Similar to Emerson UPS: Manuals for POWLI BU100XR2, POWLI BN50S, Duo II 350

-

UPS003LSM PA27224A01 Rev: 02 3-2014 UNINTERRUPTIBLE POWER SUPPLY LOAD SENSE MODULE OPERATION MANUAL © Panduit Corp. 2014 Original Instructions TO REDUCE THE RISK OF INJURY, USER MUST READ INSTRUCTION MANUAL Email: [email protected] EU Website: www.panduit.com/emea EU Email: emeatoolservic …

UPS003LSM 8

-

1Maintenance Bypass PanelModels: SU10KMBPKX, SU20KMBPKXInstallation and Operation Manual1111 W. 35th Street, Chicago, IL 60609 USA • www.tripplite.com/supportCopyright © 2019 Tripp Lite. All trademarks are the sole property of their respective owners.Contents1. Introduction …

SU10KMBPKX 32

-

COMEX S.A. CSA-2120.01 Uninterruptible Power Supply UPS COVER CORE 6-10 kVA User manual The content of this document is the copyright of the publisher and may not be reproduced without prior permission. The right to modify the design and specificat …

COVER CORE 6K 23

Popular UPS Devices: Liebert PSA, POWLI BN50S, UPS45

CONTACTING LIEBERT FOR SUPPORT

To contact Emerson Network Power Liebert Services for information or repair service in the United States, call 1-800-LIEBERT (1-800-543-2378). Liebert Services offers a complete range of start-up services, repair services, preventive maintenance plans and service contracts.

For repair or maintenance service outside the 48 contiguous United States, contact Liebert Services, if available in your area. For areas not covered by Liebert Services, the authorized distributor is responsible for providing qualified, factory-authorized service.

For Liebert Services to assist you promptly, have the following information available: Part Numbers: ________________________________________________________________

Serial Numbers: _______________________________________________________________

kVA Rating: __________________________________________________________________

Date Purchased: _______________________________________________________________

Date Installed: ________________________________________________________________

Location: _____________________________________________________________________

Input Voltage/Frequency: ______________________________________________________

Output Voltage/Frequency: _____________________________________________________

Product Warranty Registration

To register for warranty protection, visit the Service and Support section of our Web site at: www.liebert.com

Click on Product Registration and fill out the form.

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.0 SINGLE-MODULE MECHANICAL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Preliminary Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Environmental Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3.1 Room . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3.2 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4.1 Moving the Cabinets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4.2 Clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4.3 Floor Installation/Anchoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.5 Cable Entry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.6 Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.6.1 Power Cable Connection Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.0 INSTALLATION DRAWINGS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.0 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

i

|

FIGURES |

||

|

Figure 1 |

Cabinet arrangement—Liebert NXL UPS, battery cabinets, maintenance bypass cabinet. . . . . |

. 4 |

|

Figure 2 |

Two-Breaker Maintenance Bypass Cabinet, one-input, attached . . . . . . . . . . . . . . . . . . . . . . . . . |

. 7 |

|

Figure 3 |

Two-Breaker Maintenance Bypass Cabinet, two-input, attached . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

|

Figure 4 |

Two-Breaker Maintenance Bypass Cabinet, three-input, attached or detached . . . . . . . . . . . . . . |

8 |

|

Figure 5 |

Liebert NXL Maintenance Bypass Cabinet—250 and 300kVA main component location . . . . . . . |

9 |

|

Figure 6 |

Liebert NXL Maintenance Bypass Cabinet—400kVA main component location . . . . . . . . . . . . . |

10 |

|

Figure 7 |

Liebert NXL Maintenance Bypass Cabinet—250 and 300kVA outline drawing . . . . . . . . . . . . . |

11 |

|

Figure 8 |

Liebert NXL Maintenance Bypass Cabinet—400kVA outline drawing. . . . . . . . . . . . . . . . . . . . . |

12 |

|

Figure 9 |

Liebert NXL Maintenance Bypass Cabinet—250 and 300kVA terminal details . . . . . . . . . . . . . |

13 |

|

Figure 10 |

Liebert NXL Maintenance Bypass Cabinet—400Kva terminal details. . . . . . . . . . . . . . . . . . . . . |

14 |

|

Figure 11 |

Cable routing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

15 |

|

Figure 12 |

Liebert NXL Maintenance Bypass Cabinet, one-input system, point-to-point wiring |

|

|

to UPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

16 |

|

|

Figure 13 |

Liebert NXL Maintenance Bypass Cabinet, two-input system, point-to-point wiring |

|

|

to UPS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

18 |

|

|

Figure 14 |

Liebert NXL Maintenance Bypass Cabinet, three-input system, point-to-point wiring |

|

|

to UPS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

20 |

|

|

Figure 15 |

Liebert NXL Maintenance Bypass Cabinet Control wire diagram without interlock . . . . . . . . . |

22 |

|

Figure 16 |

Liebert NXL Maintenance Bypass Cabinet control wire diagram with interlock. . . . . . . . . . . . . |

23 |

|

Figure 17 |

Liebert NXL Maintenance Bypass Cabinet control wire routing. . . . . . . . . . . . . . . . . . . . . . . . . . |

24 |

|

Figure 18 |

Ground strap location for connected cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

25 |

|

TABLES |

||

|

Table 1 |

Liebert-supplied interconnect wiring for one-input Liebert NXL Maintenance |

|

|

Bypass Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

17 |

|

|

Table 2 |

Liebert-supplied interconnect wiring for two-input Liebert NXL Maintenance |

|

|

Bypass Cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

19 |

|

|

Table 3 |

Liebert-supplied interconnect wiring for three-input Liebert NXL Maintenance |

|

|

Bypass Cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

21 |

|

|

Table 4 |

Control wiring connections without interlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

22 |

|

Table 5 |

Control wiring connections with interlock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

23 |

|

Table 6 |

Liebert NXL Maintenance Bypass Cabinet specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

26 |

|

Table 7 |

Liebert NXL Maintenance Bypass Cabinet current ratings—System Input . . . . . . . . . . . . . . . . |

27 |

|

Table 8 |

Liebert NXL Maintenance Bypass Cabinet current ratings—System Output . . . . . . . . . . . . . . . |

27 |

|

Table 9 |

Recommended conduit and cable sizes—Maintenance Bypass Input . . . . . . . . . . . . . . . . . . . . . . |

27 |

|

Table 10 |

Recommended conduit and cable sizes—Rectifier Input (1-Input System) . . . . . . . . . . . . . . . . . . |

27 |

|

Table 11 |

Recommended conduit and cable sizes—Module Bypass Input . . . . . . . . . . . . . . . . . . . . . . . . . . . |

28 |

|

Table 12 |

Recommended conduit and cable sizes—Module Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

28 |

|

Table 13 |

Recommended conduit and cable sizes—Load Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

28 |

|

Table 14 |

Recommended conduit and cable sizes—Load Bank Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

28 |

|

Table 15 Recommended lug sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

29 |

ii

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important instructions that should be followed during installation of your Liebert NXL™ Maintenance Bypass Cabinet.

! WARNING

Exercise extreme care when handling cabinets to avoid equipment damage or injury to personnel. The Liebert NXL Maintenance Bypass Cabinet weight ranges from 700 to 900 lb (317 to 409kg).

Locate center of gravity symbols and determine unit weight before handling each cabinet. Test lift and balance the cabinets before transporting. Maintain minimum tilt from vertical at all times.

Slots at the base of the cabinets are intended for forklift use. Base slots will support the unit only if the forks are completely beneath the unit.

In case of fire involving electrical equipment, use only carbon dioxide fire extinguishers or those approved for use in fighting electrical fires.

Extreme caution is required when performing maintenance.

Be constantly aware that the system contains high DC as well as AC voltages. Check for voltage with both AC and DC voltmeters prior to making contact.

Read this manual thoroughly before working with the maintenance bypass cabinet. Retain this manual for use by installing personnel.

! WARNING

Under typical operation and with all doors closed, only normal safety precautions are necessary. The area around the system should be kept free of puddles of water, excess moisture and debris.

Special safety precautions are required for procedures involving handling, installation and maintenance of the Maintenance Bypass Cabinet. Observe all safety precautions in this manual before handling or installing the Maintenance Bypass Cabinet. Observe all precautions in the Operation and Maintenance Manual, before as well as during performance of all maintenance procedures.

This equipment contains circuits that are energized with high voltage. Only test equipment designed for troubleshooting should be used. This is particularly true for oscilloscopes. Always check with an AC and DC voltmeter to ensure safety before making contact or using tools. Even when the power is turned Off, dangerously high potential electric charges may exist.

All power and control wiring should be installed by a qualified electrician. All power and control wiring must comply with the NEC and applicable local codes.

ONLY properly trained and qualified personnel should perform maintenance on the Maintenance Bypass Cabinet. When performing maintenance with any part of the equipment under power, service personnel and test equipment should be standing on rubber mats. The service personnel should wear insulating shoes for isolation from direct contact with the floor ground.

One person should never work alone, even if all power is removed from the equipment. A second person should be standing by to assist and summon help in case of an accident.

! CAUTION

This unit complies with the limits for a Class A digital device, pursuant to Part 15 Subpart J of the FCC rules. These limits provide reasonable protection against harmful interference in a commercial environment. This unit generates, uses and radiates radio frequency energy and, if not installed and used in accordance with this instruction manual, may cause harmful interference to radio communications. Operation of this unit in a residential area may cause harmful interference that the user must correct at his own expense.

NOTE

Liebert Corporation neither recommends nor knowingly sells this product for use with life support or other FDA-designated “critical” devices.

1

Single-Module Mechanical Installation

1.0SINGLE-MODULE MECHANICAL INSTALLATION

1.1Introduction

This section describes the requirements that must be taken into account when planning the positioning and cabling of the Liebert NXL Maintenance Bypass Cabinet.

This chapter is a guide to general procedures and practices that should be observed by the installing engineer. The particular conditions of each site will determine the applicability of such procedures.

! WARNING

Do not apply electrical power to the UPS equipment before the arrival of the commissioning engineer.

! WARNING

The Maintenance Bypass Cabinet should be installed by a qualified engineer in accordance with the information contained in this chapter and all equipment not referred to this manual is shipped with details of its own mechanical and electrical installation.

! WARNING

Eye protection should be worn to prevent injury from accidental electrical arcs. Remove rings, watches and all metal objects. Only use tools with insulated handles. Wear rubber gloves.

NOTICE

Three-phase input supply required.

The standard Liebert NXL UPS is suitable for connection to three-phase, four-wire (+ Earth) TN-C, TN-S, IT-G, IT-IG or three-phase, three-wire plus ground, IT-UG.

If using the Liebert NXL UPS with an IT Power system, a four-pole disconnect device must be included as part of building installation.

1.2Preliminary Checks

Before installing the Maintenance Bypass Cabinet, carry out the following preliminary checks:

•Visually examine the equipment for transit damage, both internally and externally. Report any damage to the shipper immediately.

•Verify that the correct equipment is being installed. The equipment supplied has an identification tag on the back of the main door reporting: the type, size and main calibration parameters of the UPS.

•Verify that the room satisfies the environmental conditions stipulated in the equipment specifications, paying particular attention to the ambient temperature and air exchange system.

1.3Environmental Considerations

1.3.1Room

The Maintenance Bypass Cabinet is intended for indoor installation and should be located in a cool, dry, clean-air environment with adequate ventilation to keep the ambient temperature within the specified operating range (see 3.0 — Specifications).

All models of the Liebert NXL Maintenance Bypass Cabinet are convection-cooled. To permit air to enter and exit and prevent overheating or malfunctioning, do not cover the ventilation openings.

When bottom entry is used, the conduit plate can be removed and punched and replaced. The bottom conduit plate must be replaced for proper airflow. If necessary to cool the room, install a system of room extractor fans.

NOTE

The Maintenance Bypass Cabinet is suitable for mounting on concrete or other noncombustible surface only.

2

Single-Module Mechanical Installation

1.3.2Storage

Should the equipment not be installed immediately, it must be stored in a room for protection against excessive humidity and or heat sources (see Table 6).

1.4Positioning

The cabinet is structurally designed to handle lifting from the base.

Access to the power terminals, auxiliary terminals blocks and power switches is from the front.

The top and front removable panels are secured to the chassis by screws. The door can be opened to give access to the power connections bars, auxiliary terminal blocks and power isolators. Front door can be opened at 180° for better Service and more flexibility in installations.

1.4.1Moving the Cabinets

The route to be travelled between the point of arrival and the unit’s position must be planned to make sure that all passages are wide enough for the unit and that floors are capable of supporting its weight (for instance, check that doorways, lifts, ramps, etc. are adequate and that there are no impassable corners or changes in the level of corridors).

Ensure that the cabinet weight is within the designated surface weight loading (kg/cm2) of any handling equipment. See Table 6 for weight.

Ensure that any lifting equipment used in moving the cabinet has sufficient lifting capacity.

The Maintenance Bypass Cabinet can be handled by means of a fork lift or similar equipment. For operations with a fork lift, refer to installation drawings in 2.0 — Installation Drawings.

Because the weight distribution in the cabinet is uneven, use extreme care during handling and transporting.

When moving the unit by forklift, care must be taken to protect the panels. Do not exceed a 15-degree tilt with the forklift. Bottom structure will support the unit only if the forks are completely beneath the unit.

Handling the unit with straps is not authorized.

! CAUTION

Take extreme care when handling Maintenance Bypass Cabinets to avoid equipment damage or injury to personnel.

1.4.2Clearances

Liebert NXL Maintenance Bypass Cabinets have no ventilation grilles at either side or at the rear. Clearance around the front of the equipment should be sufficient to enable free passage of personnel with the doors fully opened. It is important to leave a distance of 24″ (610mm) between the top of the cabinet and any overhead obstacles to permit adequate circulation of air coming out of the unit.

1.4.3Floor Installation/Anchoring

The installation diagrams in 2.0 — Installation Drawings of this manual identify the location of the holes in the base plate through which the equipment can be bolted to the floor. If the equipment is to be located on a raised floor it should be mounted on a pedestal suitably designed to accept the equipment point loading. Refer to the base view to design this pedestal.

1.5Cable Entry

Cables can enter the Maintenance Bypass Cabinet from the bottom or top.

3

Single-Module Mechanical Installation

1.6Power Cables

The Maintenance Bypass Cabinet requires both power and control cabling once it has been mechanically installed. All control cables must be separate from the power cables. Run control cables in metal conduits or metal ducts that are electrically bonded to the cabinets they are connected to.

The cable design must comply with the voltages and currents provided in Tables 7 and 8, follow local wiring practices and take into consideration the environmental conditions (temperature and physical support media).

For cable entry terminal, refer to Figure 9.

! WARNING

Before cabling up the cabinet, ensure that you are aware of the location and operation of the external isolators that connect the input/bypass supply.

Check that these supplies are electrically isolated, and post any necessary warning signs to prevent their inadvertent operation.

The following are guidelines only and superseded by local regulations and codes of practice where applicable:

•Take special care when determining the size of the neutral cable (grounded conductor), because current circulating on the neutral cable may be greater than nominal current in the case of nonlinear loads. Refer to Tables 7 and 8.

•The grounding conductor should be sized according to the fault rating, cable lengths, type of protection, etc. The grounding cable connecting the UPS to the main ground system must follow the most direct route possible.

•Consider using smaller, paralleled cables for heavy currents as a way of easing installation.

Figure 1 Cabinet arrangement—Liebert NXL UPS, battery cabinets, maintenance bypass cabinet

Liebert

NXL

UPS

|

Maintenance |

Note: If a maintenance bypass |

|

cabinet is used, it must be |

|

|

Bypass |

installed on the right side of |

|

Cabinet |

the Liebert NXL UPS |

|

Additional |

Battery |

Liebert |

Maintenance |

|

|

Battery |

NXL |

Bypass |

||

|

Cabinet |

||||

|

Cabinet(s) |

UPS |

Cabinet |

||

Additional

Battery Battery

Cabinet(s) Cabinet

Additional

Battery Battery

Cabinet Cabinet(s)

4

Single-Module Mechanical Installation

1.6.1Power Cable Connection Procedure

The system input, UPS bypass, UPS output and system output cables (all require lug type terminations) are connected to busbars situated behind the power isolator switches as shown in 2.0 — Installation Drawings. These are accessible when the power compartment door is opened.

Equipment Ground

The equipment ground busbar is located near the input and output power supply connections as shown in 2.0 — Installation Drawings. The grounding conductor must be connected to the ground busbar.

All cabinets and cable trunking should be grounded in accordance with local regulations.

! WARNING

Failure to follow adequate grounding procedures can result in electric shock hazard to personnel, or the risk of fire, should an ground fault occur.

! WARNING

The operations described in this section must be performed by authorized electricians or qualified technical personnel. If you have any difficulties, do not hesitate to contact Emerson Network Power Liebert Services. See the back page of this manual for contact information.

NOTE

Proper grounding considerably reduces problems in systems caused by electromagnetic interference.

5

Single-Module Mechanical Installation

Once the equipment has been finally positioned and secured, connect the power cables as described in the following procedure.

Refer to the appropriate cable connection drawing in 2.0 — Installation Drawings.

1.Verify that the bypass equipment is isolated from its external power source and all the power isolators are open. Check that these supplies are electrically isolated and post any necessary warning signs to prevent their inadvertent operation.

2.Open the door to the cabinet and remove the interior panels.

3.Connect the ground and any necessary main bonding jumper to the equipment ground busbar.

NOTE

The grounding and neutral bonding arrangement must be in accordance with local and national codes of practice.

NOTE

Care must be taken when routing power cable. Ensure that cables do not touch other busbars (see Figure 11).

NOTE

Do not double-stack lugs: do not layer two lugs on the same side of the busbar (see Figure 11).

4.Connect the AC input supply cables between the power distribution panel and the bypass input supply busbars (A-B-C or A-B-C-N terminals) and tighten the connections to the proper torque. Ensure correct phase rotation!

5.If system is oneor two-input, connect the AC input supply cables between the maintenance bypass cabinet and the UPS bypass input supply busbars (A-B-C or A-B-C-N terminals) and tighten the connections to the proper torque.

Ensure correct phase rotation!

6.If system is single-input, connect AC jumper connectors between UPS bypass input supply busbars and UPS rectifier input supply busbars (A-B-C terminals) and tighten the connections to the proper torque.

Ensure correct phase rotation!

7.Connect the system output power cables between the Maintenance Bypass Cabinet output (A-B-C or A-B-C-N terminals) and the critical load and tighten the connections to the proper torque. Ensure correct phase rotation!

8.Connect the auxiliary cables of any external interface/signals to the respective connections of the output auxiliary terminal block (X4) (see2.0 — Installation Drawings).

9.Replace interior panels and close door.

6

Installation Drawings

2.0INSTALLATION DRAWINGS

Figure 2 Two-Breaker Maintenance Bypass Cabinet, one-input, attached

Two Breaker Maintenance Bypass Cabinet

Critical

Load

Load Bank

(FBO)

|

BFB |

|||

|

CB1 |

DC Bus |

CB2 |

|

|

Main Input |

N |

||

|

Switchgear |

UPS Module |

MBJ |

|

|

EG |

|||

|

Battery |

MIB — Maintenance Isolation Breaker |

||

|

MBB — Maintenance Bypass Breaker |

|||

|

System |

MBD |

||

|

FBO – Furnished By Others |

|||

|

N – Neutral |

|||

|

EG – Equipment Ground |

|||

|

MBJ – Main Bonding Jumper(3-wire systems only) |

|||

|

I — Option Interlock |

7

Найди любой мануал:

Например: Sony VGN-FW460J/T

Вы можете бесплатно скачать Руководство пользователя для Emerson Liebert APM On-line UPS 15-90kW.

Также вы сможете прочесть онлайн этот документ без скачивания.

Скачать Руководство пользователя для Emerson Liebert APM On-line UPS 15-90kW

Тип файла

PDF

Размер

8.89 Mb

Кол-во страниц

56

Просмотров

1238

Читать онлайн Руководство пользователя для Emerson Liebert APM On-line UPS 15-90kW (Страница 1)

Другие ИБП для дата-центров и заводов Emerson Liebert APM On-line UPS 15-90kW

Топ Emerson ИБП для дата-центров и заводов

Вопросы

Ранее вы смотрели

Эта страница полезна для вас? Поделитесь ссылкой: